Reduced graphene oxide/stannate sodium ion battery negative electrode material and preparation method and application thereof

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as capacity decay, limit practical applications, volume expansion, etc., and achieve improved conductivity , Improve the effect of volume expansion, and the effect of easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

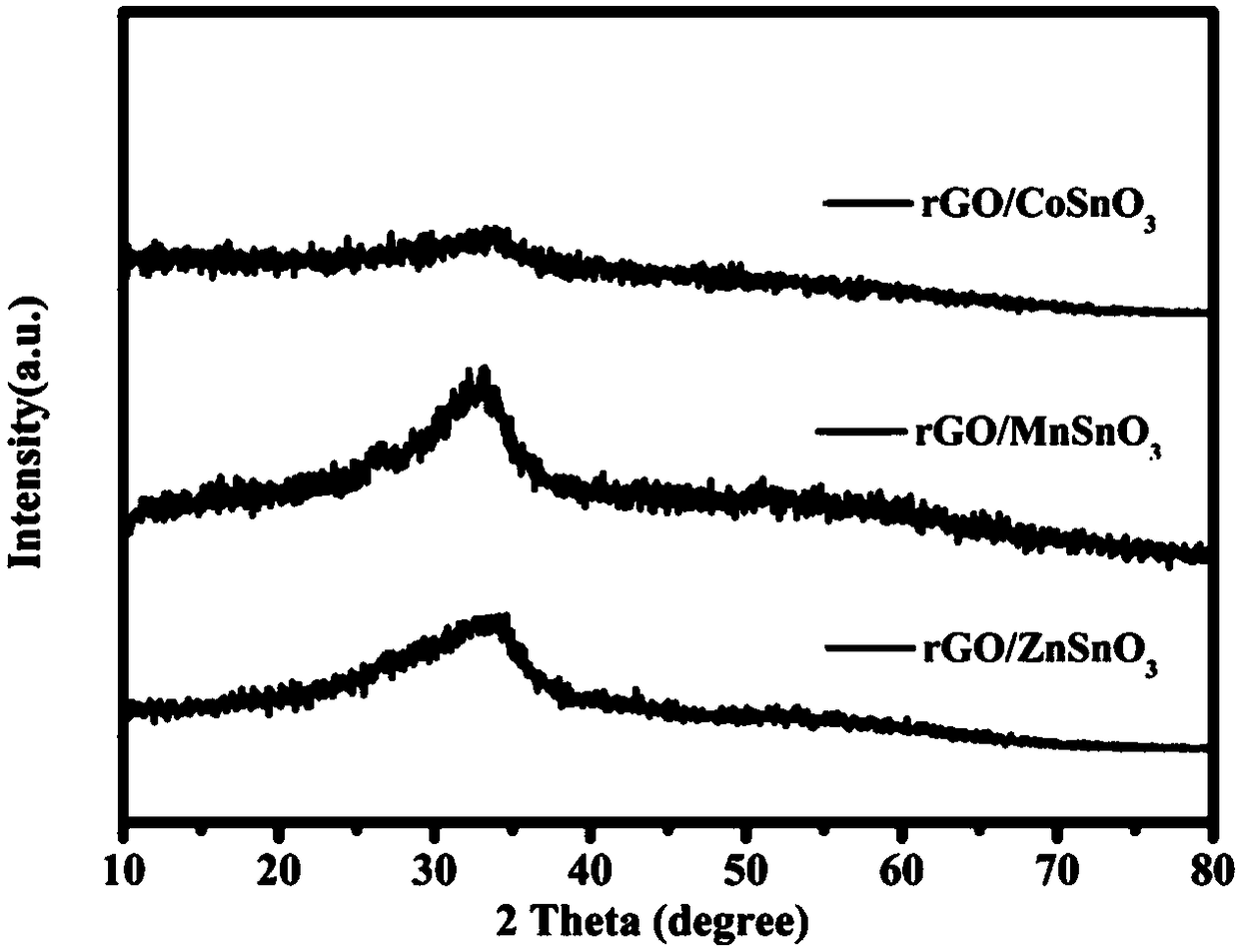

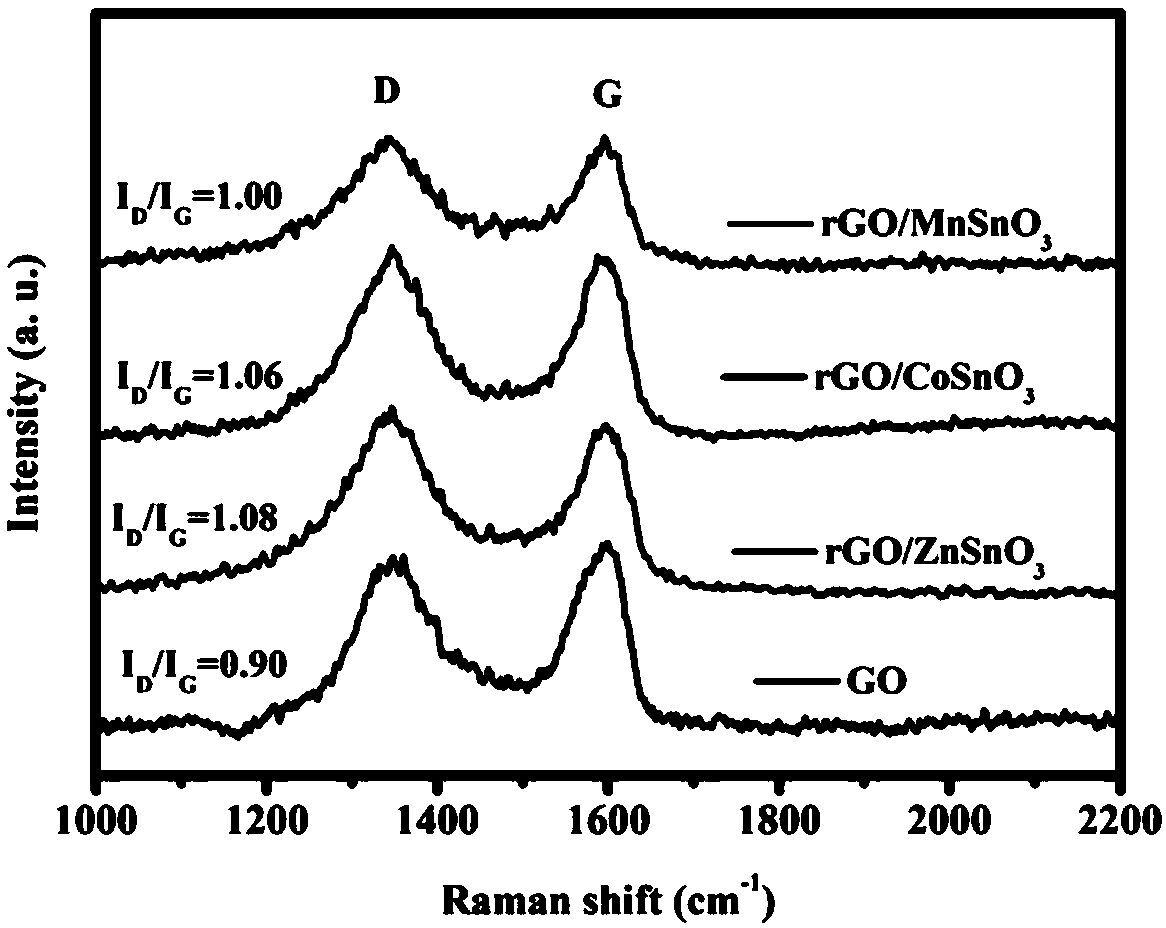

[0067] In the present embodiment, a method for preparing a negative electrode material for a reduced graphene oxide / stannate (manganese stannate) sodium ion battery comprises the following steps:

[0068] Step 1. First, dissolve 0.5mmol manganese chloride and 0.5mmol sodium stannate in 10mL deionized water, stir for 2 hours, and then add 20mL graphene oxide solution (20mg graphene oxide is dissolved in 20mL deionized water, at a power of 300w conditions, ultrasonic cleaning 3h), and then magnetic stirring for 1h;

[0069] Step 2, then transfer to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and heat and react at 180° C. for 24 hours. Cool to room temperature to obtain a suspension;

[0070] Step 3: Filtrate the suspension in step 2 to obtain a precipitate, which is washed three times with deionized water and absolute ethanol in sequence; and vacuum-dried at 60° C. for 12 hours. The reduced graphene oxide / stannate (manganese stannate) battery negative electro...

Embodiment 2

[0074] In the present embodiment, a method for preparing a negative electrode material for a reduced graphene oxide / stannate (cobalt stannate) sodium ion battery comprises the following steps:

[0075] Step 1, first take 0.5mmol cobalt chloride hexahydrate, 0.5mmol sodium stannate dissolved in 10mL deionized water, stir for 2h, then add 20mL graphene oxide solution (20mg graphene oxide is dissolved in 20mL deionized water, at power Under the condition of 300w, ultrasonic cleaning for 3h), and then magnetic stirring for 1h;

[0076] Step 2, then transfer to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and heat and react at 180° C. for 24 hours. Cool to room temperature to obtain a suspension;

[0077] Step 3: Filtrate the suspension in step 2 to obtain a precipitate, which is washed three times with deionized water and absolute ethanol in sequence; and vacuum-dried at 60° C. for 12 hours. The reduced graphene oxide / stannate (cobalt stannate) battery negative ...

Embodiment 3

[0081] In the present embodiment, a method for preparing a negative electrode material for a reduced graphene oxide / stannate (zinc stannate) sodium ion battery comprises the following steps:

[0082] Step 1. First, dissolve 0.5mmol zinc chloride and 0.5mmol sodium stannate in 10mL deionized water, stir for 2 hours, and then add 20mL graphene oxide solution (20mg graphene oxide is dissolved in 20mL deionized water, at a power of 300w conditions, ultrasonic cleaning 3h), and then magnetic stirring for 1h;

[0083] Step 2, then transfer to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and heat and react at 180° C. for 24 hours. Cool to room temperature to obtain a suspension;

[0084] Step 3: Filtrate the suspension in step 2 to obtain a precipitate, which is washed three times with deionized water and absolute ethanol in sequence; and vacuum-dried at 60° C. for 12 hours. The reduced graphene oxide / stannate (zinc stannate) battery negative electrode material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com