Graphene coated p@sno 2 Core-shell quantum dot electrode material and its preparation method and application

A core-shell quantum dot and graphene-coated technology, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of low lithium ion conductivity and damage cycle performance, achieve good cycle stability, reduce diffusion paths, and ensure stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Graphene-coated P@SnO 2 The preparation method of core-shell quantum dot electrode material, it comprises the steps:

[0028] 1) Prepare graphene (GO, ~2mg / mL) by the Hummer method;

[0029] 2) Add 0.379g of anhydrous stannous chloride to ethanolamine and stir to dissolve to obtain a solution; then sequentially add 0.0465g of red phosphorus and 5mL of graphene to obtain a black solution in an ultrasonic machine with a power of 80Hz for 1h;

[0030] 3) Transfer the black solution to the reaction kettle and heat it in an oven at 200°C for 12 hours, wash it with alcohol for 5 times after cooling, and dry the final graphene-coated P@SnO 2 Core-shell quantum dot electrode materials.

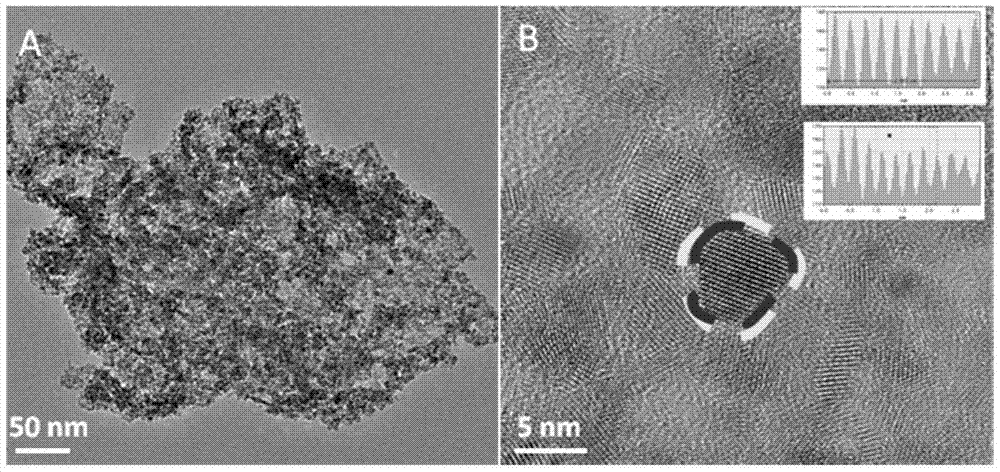

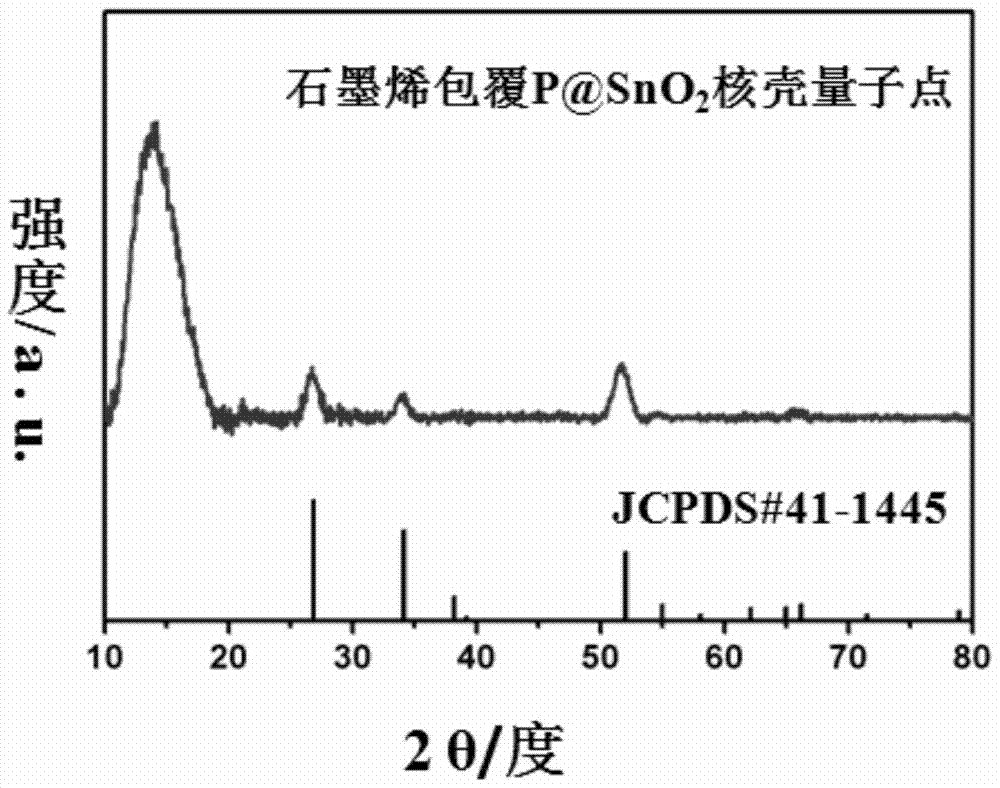

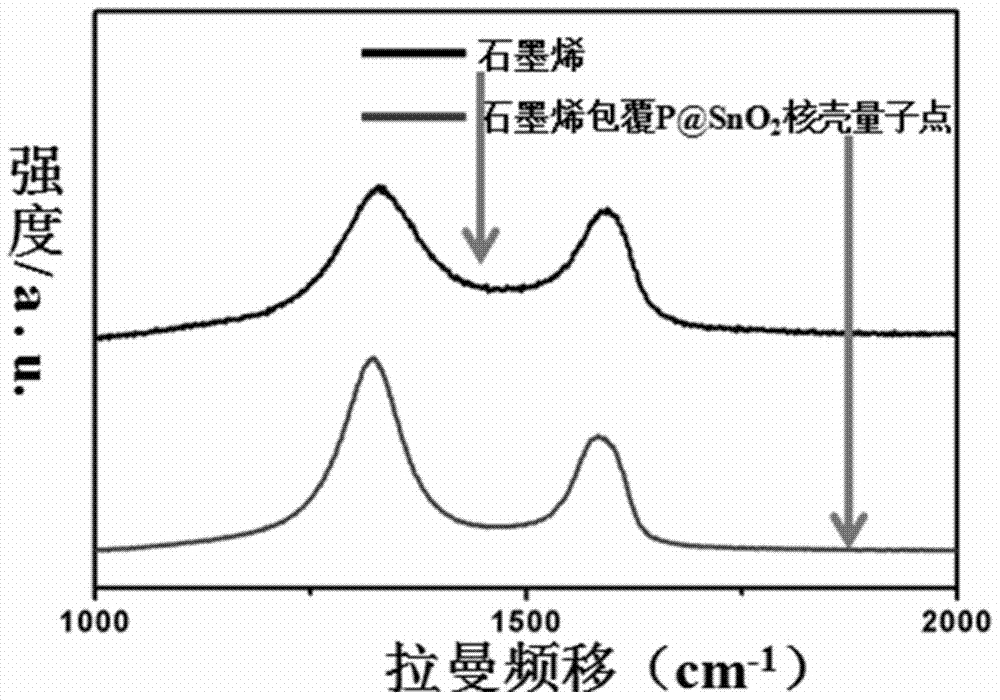

[0031] as attached figure 1 The shown TEM image shows amorphous P-coated SnO 2 The quantum dots become a core-shell structure, these quantum dots are evenly distributed on the graphene, and the size of the core-shell structure is 2-10nm;

[0032] Coated P@SnO with graphene in this example ...

Embodiment 2

[0037] 1) Prepare graphene (GO, ~2mg / mL) by the Hummer method;

[0038] 2) Add 0.379g of anhydrous stannous chloride to ethanolamine and stir to dissolve to obtain a solution; then sequentially add 0.0465g of red phosphorus and 5mL of graphene to obtain a black solution in an ultrasonic machine with a power of 80Hz for 1h;

[0039] 3) Transfer the black solution to the reactor and heat it in an oven at 200°C for 6 hours, wash it with alcohol for 5 times after cooling, and dry the final graphene-coated P@SnO 2 Core-shell quantum dot negative electrode material.

[0040] Coating P@SnO with the graphene obtained in this example 2Core-shell quantum dots as an example, at a current density of 1000mAh / g, graphene-coated P@SnO 2 The second discharge specific capacity of the core-shell quantum dots can reach 399mAh / g, after 700 cycles the discharge specific capacity is 300mAh / g, and the capacity retention rate is 75.1%.

Embodiment 3

[0042] 1) Prepare graphene (GO, ~2mg / mL) by the Hummer method;

[0043] 2) Add 0.379g of anhydrous stannous chloride to ethanolamine and stir to dissolve to obtain a solution; then sequentially add 0.0465g of red phosphorus and 2mL of graphene to obtain a black solution in an ultrasonic machine with a power of 80Hz for 1h;

[0044] 3) Transfer the black solution to the reaction kettle and heat it in an oven at 200°C for 12 hours, wash it with alcohol for 5 times after cooling, and dry the final graphene-coated P@SnO 2 Core-shell quantum dot electrode materials.

[0045] Coating P@SnO with the graphene obtained in this example 2 Core-shell quantum dots as an example, at a current density of 1000mAh / g, graphene-coated P@SnO 2 The second discharge specific capacity of the core-shell quantum dots can reach 405mAh / g, after 700 cycles the discharge specific capacity is 280mAh / g, and the capacity retention rate is 69.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com