A kind of porous silicon-copper composite material and its preparation method and application

A composite material and porous silicon technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of high energy consumption, unsuitability for large-scale industrial production, and high equipment requirements, and achieve large specific surface area, excellent performance, The effect of uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) CuO, Mg 2 Si is uniformly mixed in a mass ratio of 2:1.

[0032] 2) The homogeneously mixed raw materials are heat-treated at 600° C. for 10 h, and the heat treatment process is carried out under a protective atmosphere of argon.

[0033] 3) Treat the product obtained in step 2) in a certain concentration of hydrochloric acid for 5 hours, the concentration of hydrochloric acid is 0.2 mol / liter, after the acid treatment, use deionized water to wash 3 times, then centrifuge, and finally carry out vacuum drying.

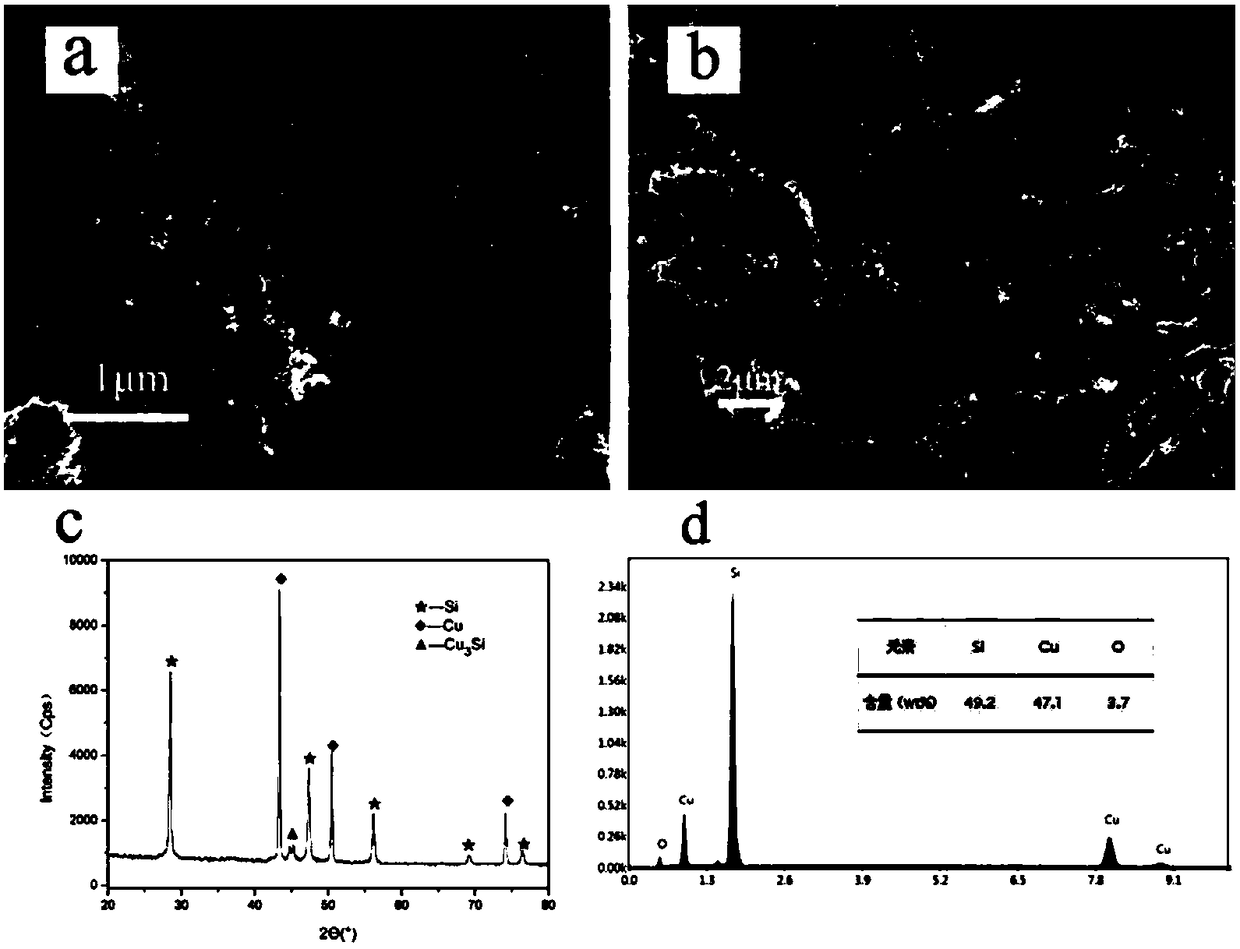

[0034] The product prepared in this example is a porous silicon-copper composite material, and its morphology and structural characterization are as follows: figure 1 shown by figure 1 It can be seen that the particles of porous silicon-copper are about 2-10 μm, and countless nanoscale holes are evenly distributed on the surface and inside of the particles. The overall mass fraction of copper is 47.1%, which is mainly composed of elemental copper and the mol...

Embodiment 2

[0040] 1) CuO, Mg 2 Si is uniformly mixed in a mass ratio of 1:1.

[0041] 2) The homogeneously mixed raw materials were heat-treated at 650° C. for 9 hours, and the heat treatment process was carried out under the protective atmosphere of argon.

[0042] 3) The product obtained in step 2) was treated for 4 hours in a certain concentration of hydrochloric acid and hydrofluoric acid solution, the concentration of hydrochloric acid was 2.0 mol / liter, and then washed 4 times with deionized water, then centrifuged, and finally vacuum-dried.

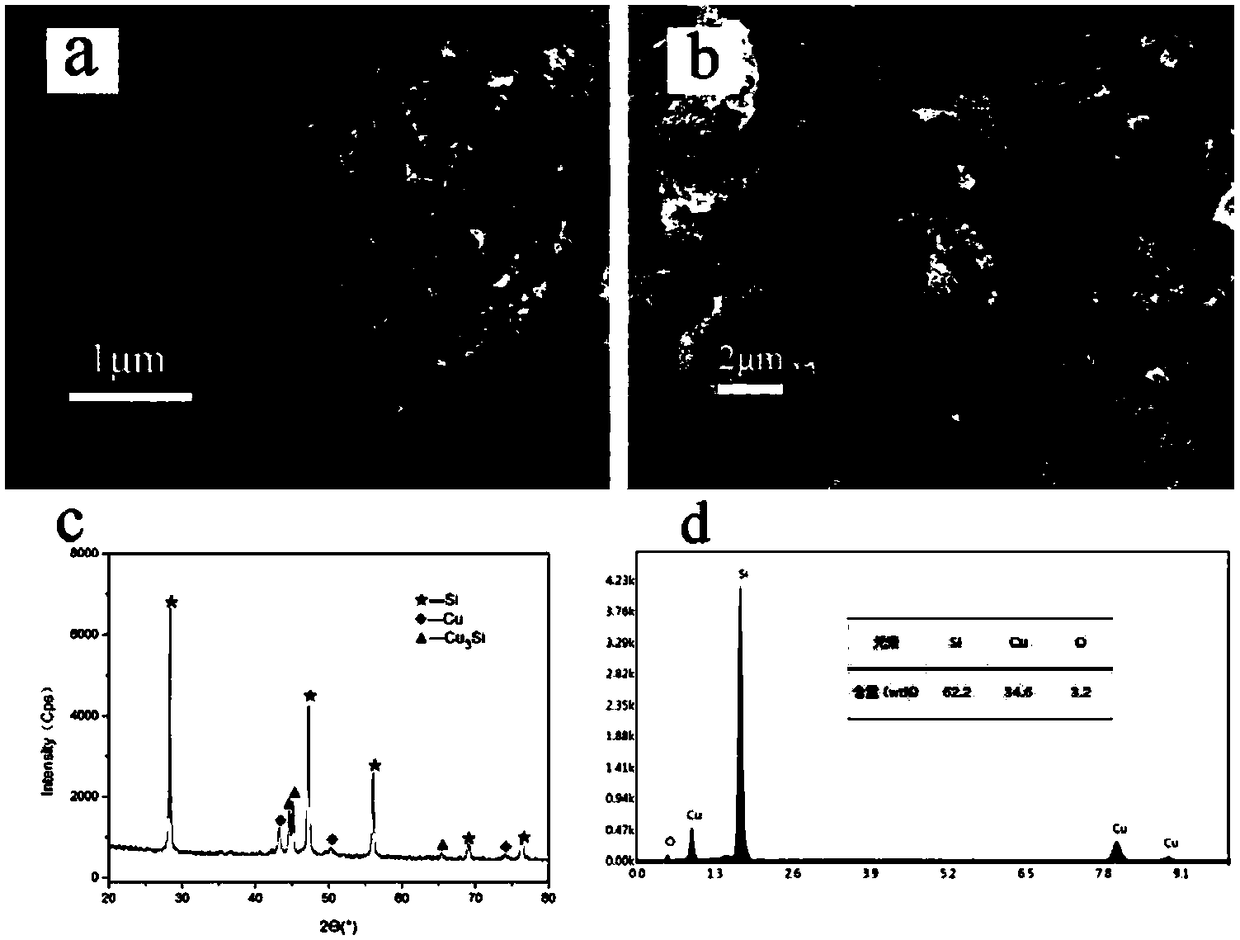

[0043] The product obtained in this embodiment is a porous silicon-copper composite material, wherein about half of Cu and Si have formed a molecular formula of Cu 3 Copper-silicon alloy of Si, the overall mass fraction of copper is 34.6%.

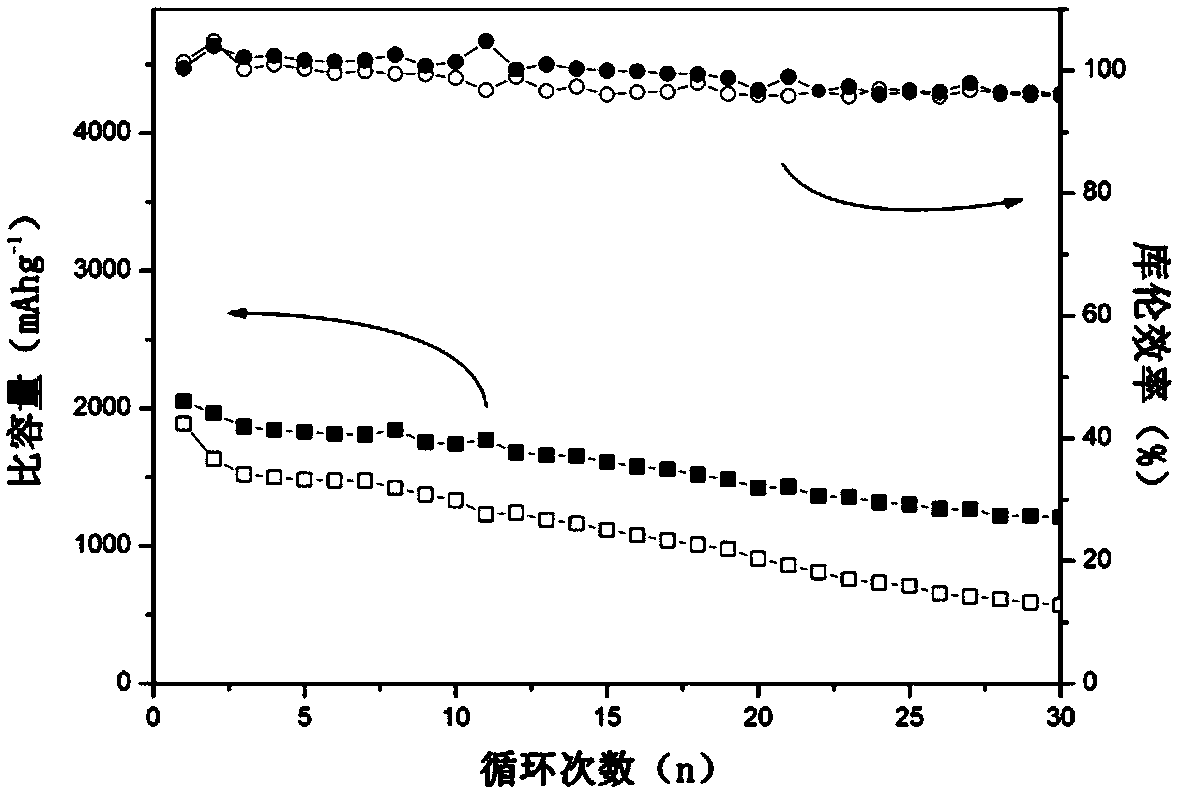

[0044] The porous silicon-copper prepared in this example was made into a button battery for lithium battery performance testing, and compared with ordinary porous silicon to obtain a comparison chart o...

Embodiment 3

[0046] 1) CuO, Mg 2 Si is uniformly mixed in a mass ratio of 1:1.

[0047] 2) The homogeneously mixed raw materials were heat-treated at 700° C. for 8 hours, and the heat treatment process was carried out under the protective atmosphere of argon.

[0048] 3) The product obtained in step 2) was treated in a certain concentration of hydrochloric acid for 3 hours, and the concentration of hydrochloric acid was 5 mol / liter, and then washed 5 times with deionized water, then centrifuged, and finally vacuum-dried.

[0049] The product obtained in this embodiment is a porous silicon-copper composite material, wherein most of Cu and Si form a molecular formula of Cu 3 Copper-silicon alloy of Si, the overall mass fraction of copper is 35.8%.

[0050] The porous silicon-copper prepared in the above example was made into a button battery for lithium battery performance testing, and compared with ordinary porous silicon to obtain a comparison chart of cycle capacity curve and Coulombic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com