Pressure-responsive fragrant sustained-release microcapsule, and preparation method and application thereof

An aroma sustained-release and microcapsule technology, which is applied in microcapsule preparations, microsphere preparation, essential oils/flavors, etc., can solve the problems of waste of raw materials, low service life, and poor fragrance release effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

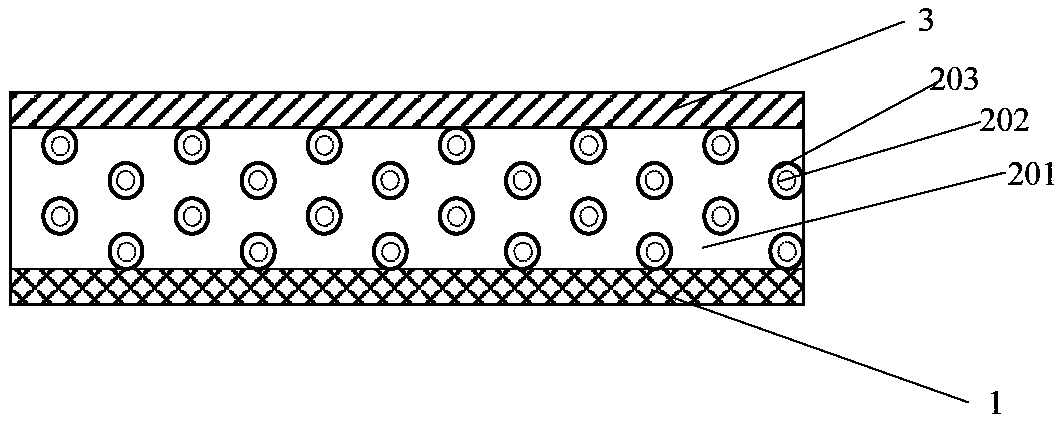

Image

Examples

Embodiment 1

[0043] A method for preparing pressure-responsive aromatic slow-release microcapsules, the specific steps are as follows:

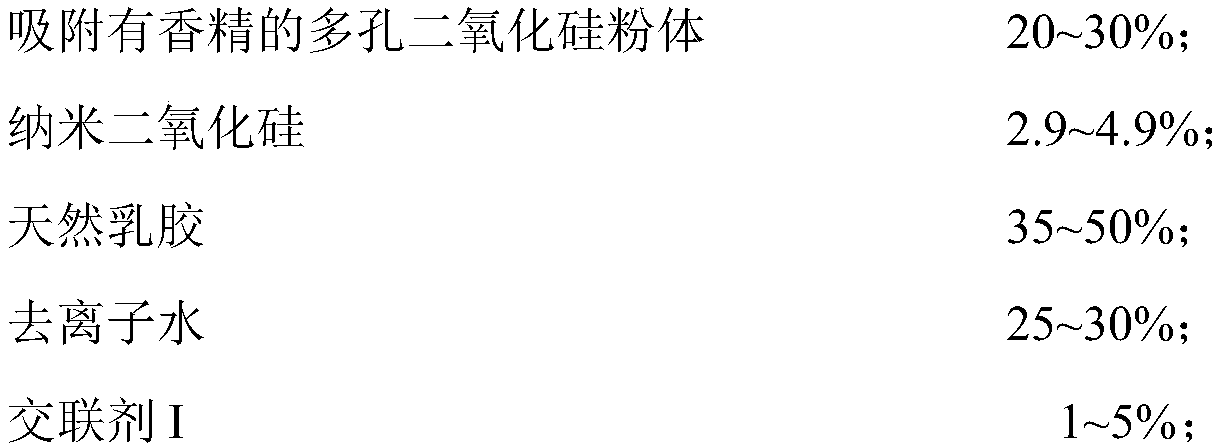

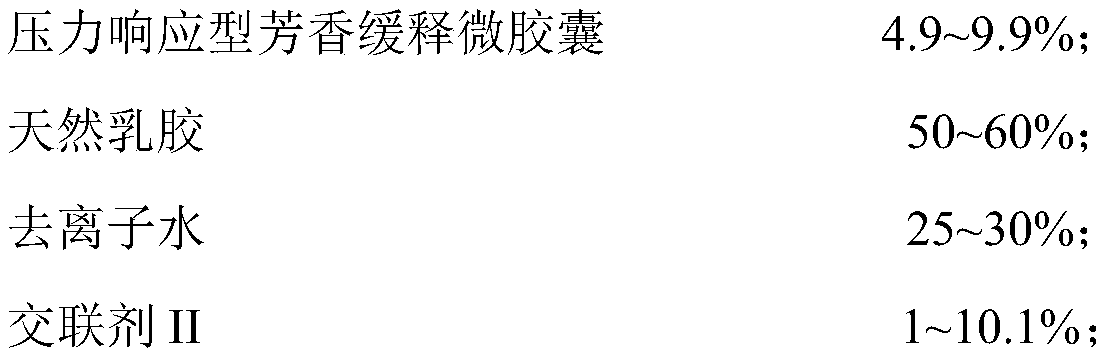

[0044] (1) Preparation of porous silica powder adsorbed with plant essential oil: use porous silica powder as the adsorption material to absorb plant essential oil at 80°C for 45min, filter while hot and wash with ethanol three times, and then Dry at room temperature and -0.05MPa for 48 hours to obtain porous silica powder adsorbed with essence, wherein the average particle size of the porous silica powder is 1.0 μm, the porosity is 30%, and the specific surface area is 300m 2 / g, the mass ratio of silicon dioxide powder and plant essential oil is 1:100;

[0045] (2) Disperse the porous silica powder adsorbed with plant essential oil in deionized water whose stirring speed is 6000r / min;

[0046] (3) After adding nano-silica, natural latex and cross-linking agent XR-500 and cross-linking at 60°C for 15 minutes, cross-linking at 85°C for 10 minutes to prep...

Embodiment 2

[0058] A method for preparing pressure-responsive aromatic slow-release microcapsules, the specific steps are as follows:

[0059] (1) Preparation of porous silica powder adsorbed with grapefruit essence: use porous silica powder as the adsorption material to absorb grapefruit essence at 60°C for 25 minutes, filter while hot and wash with ethanol three times, Then dry at room temperature and -0.05MPa for 48 hours to obtain a porous silica powder adsorbed with essence, wherein the average particle diameter of the porous silica powder is 0.5 μm, the porosity is 30%, and the specific surface area is 150m 2 / g, the mass ratio of silicon dioxide powder and grapefruit essence is 1:10;

[0060] (2) Disperse the porous silica powder adsorbed with grapefruit essence in deionized water whose stirring speed is 3000r / min;

[0061] (3) After adding nano-silica, natural latex and cross-linking agent XR-500, cross-linking at 45°C for 15 minutes, and then cross-linking at 70°C for 10 minutes...

Embodiment 3

[0071] A method for preparing pressure-responsive aromatic slow-release microcapsules, the specific steps are as follows:

[0072] (1) Preparation of porous silica powder adsorbed with lemon essence: use porous silica powder as the adsorption material, after adsorbing lemon essence at 75°C for 35 minutes, filter while hot and wash with ethanol three times, then in room temperature , Dry for 48 hours under the condition of -0.05MPa to obtain porous silica powder with essence adsorbed, wherein the average particle size of the porous silica powder is 0.5μm, the porosity is 30%, and the specific surface area is 200m 2 / g, the mass ratio of silicon dioxide powder and lemon essence is 1:50;

[0073] (2) Disperse the porous silica powder adsorbed with lemon essence in deionized water whose stirring speed is 6000r / min;

[0074] (3) After adding nano-silica, natural latex and cross-linking agent XR-500, cross-linking at 60°C for 15 minutes, cross-linking at 85°C for 5 minutes to prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com