Magnetic powder concentration sensor of magnetic suspension

A concentration sensor and magnetic suspension technology, applied in the field of concentration sensors, can solve the problems of inaccurate detection results, affecting the quality of magnetic particle flaw detection of rail vehicle parts, and the inability to realize real-time detection, etc., and achieve the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

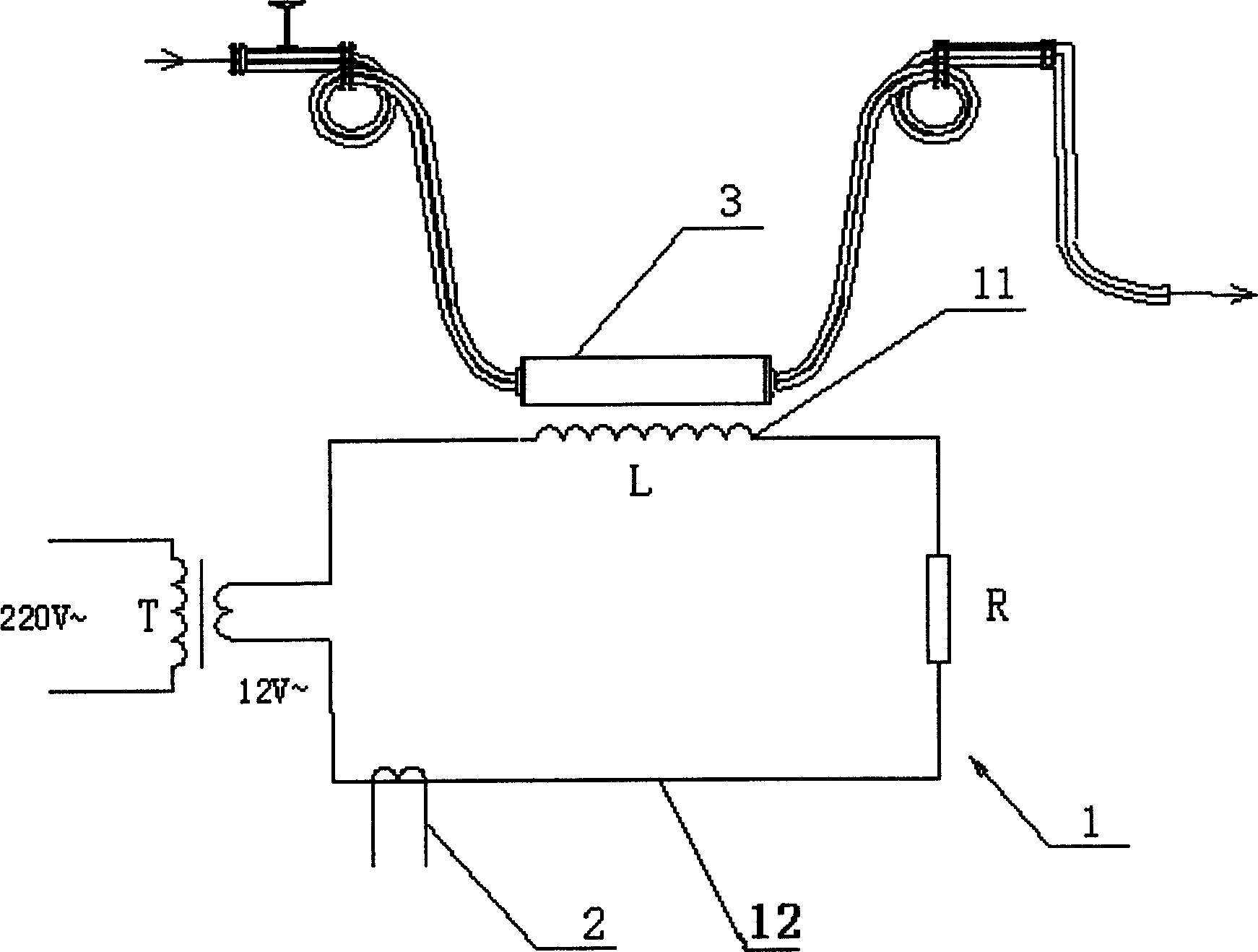

[0009] A magnetic suspension liquid magnetic particle concentration sensor used in a magnetic particle flaw detection system for rail vehicle parts, which is composed of an inductance coil loop 1, a current sensor 2 and a non-magnetic tube 3, and the inductance coil loop 1 is composed of an inductance coil 11 and a current sensing line 12 The non-magnetic tube 3 is arranged in the inductance coil 11 of the inductance coil circuit 1. One end of the non-magnetic tube 3 is the inlet of the magnetic suspension, and the other end is the outlet of the magnetic suspension. The current sensor 2 is set in the induction coil circuit 1. On the current sensing line 12, the above-mentioned current sensor 2 adopts a current sensor whose model is WBI4114aD1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com