Method and device for flaw detection of magnetic powder

A technology of magnetic particle inspection and magnetization device, applied in the direction of material magnetic variables, can solve problems such as difficult inspection defects, and achieve the effect of high-precision magnetic particle inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

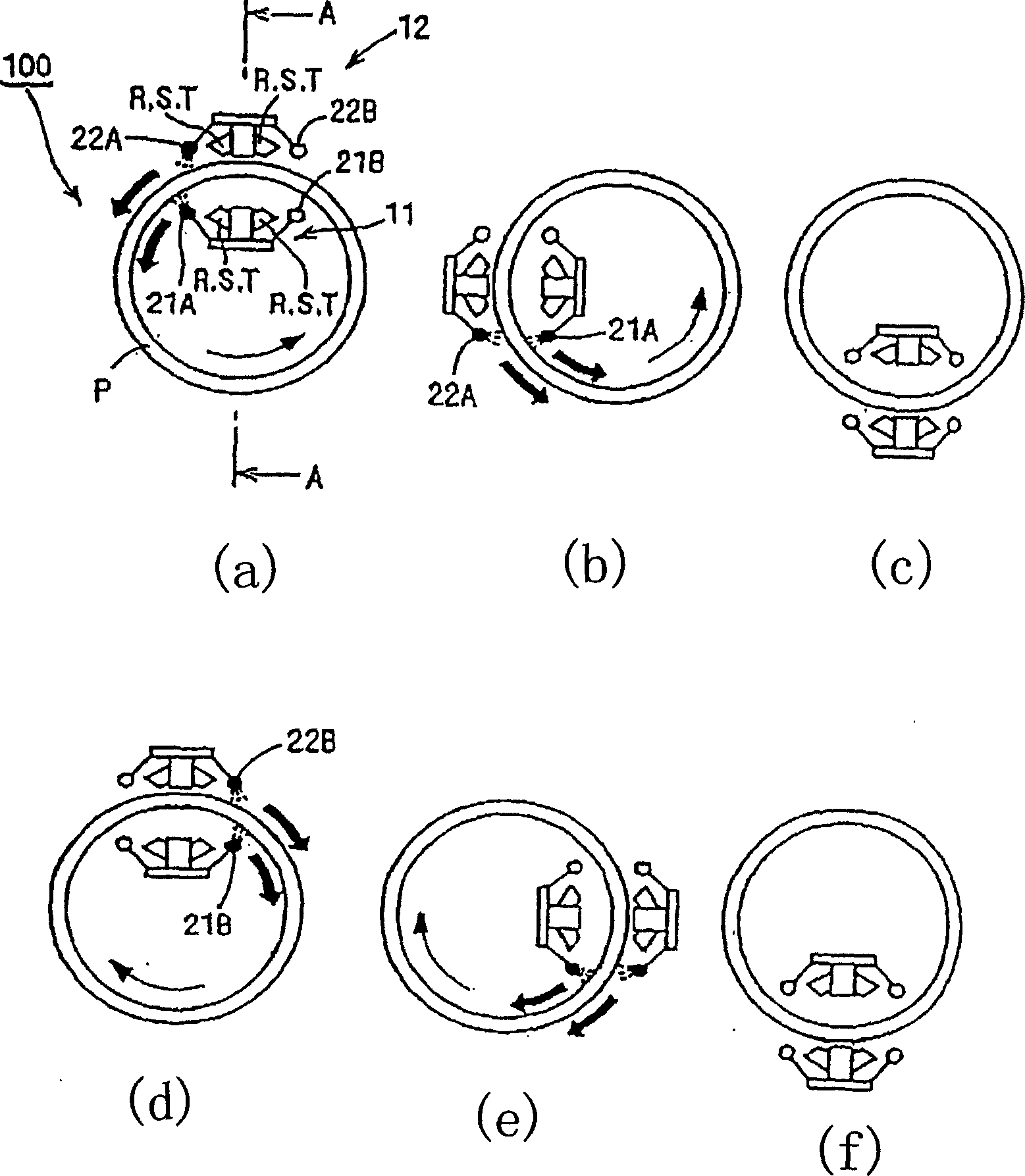

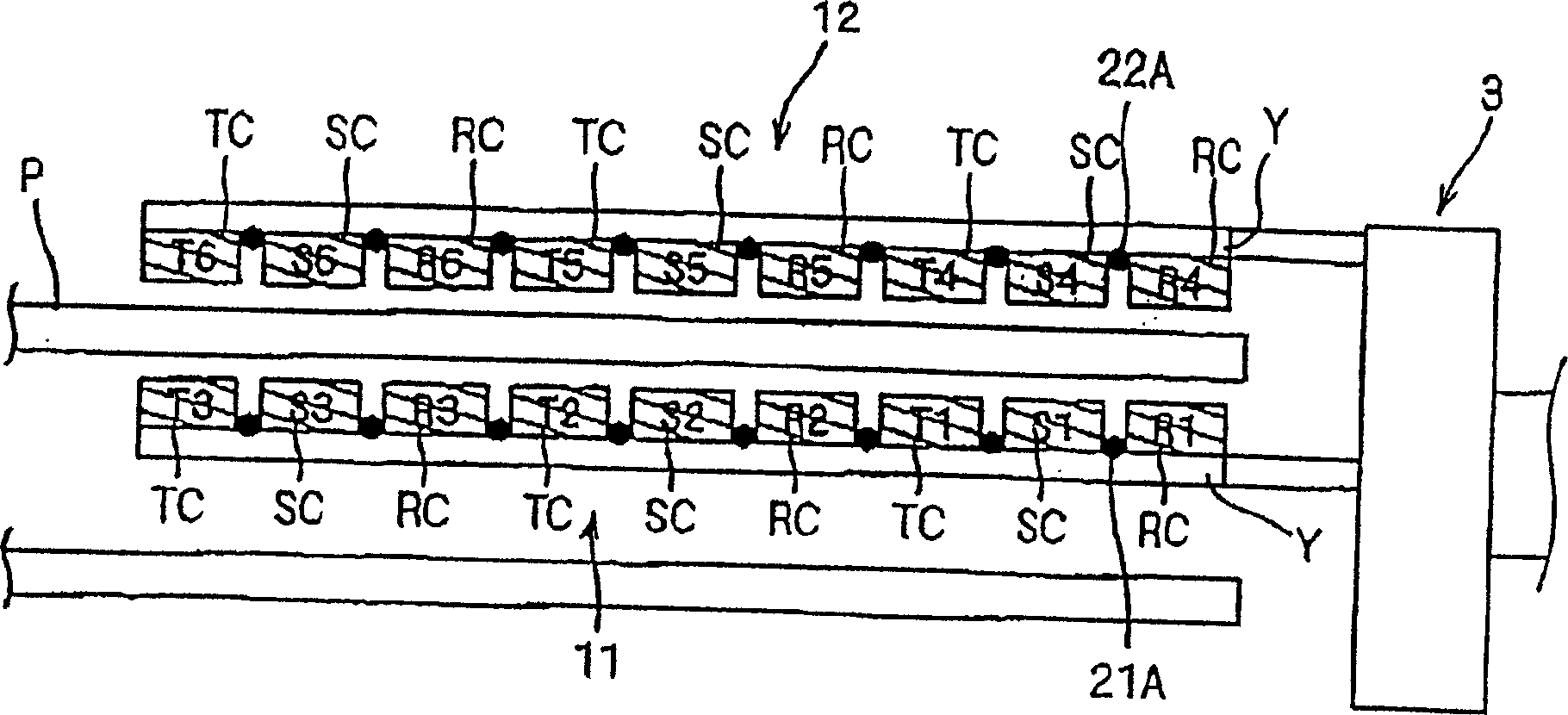

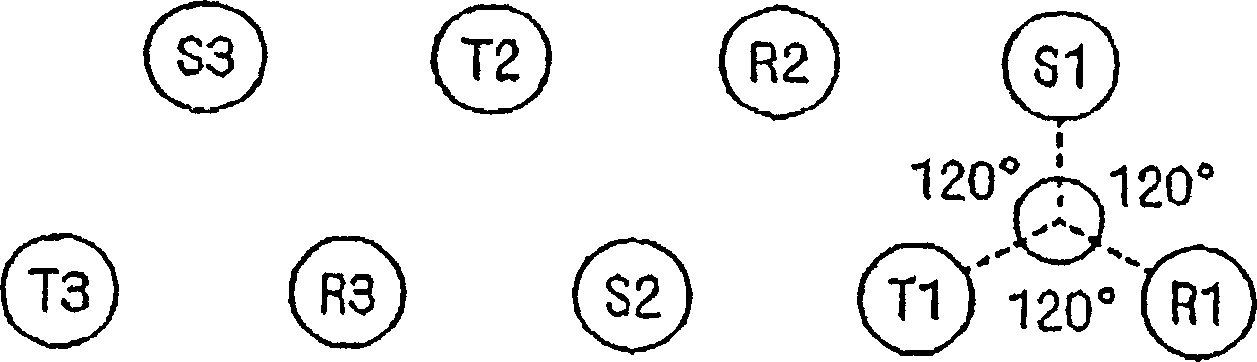

[0049] Hereinafter, the best mode for carrying out the magnetic particle inspection method and the magnetic particle inspection apparatus of the present invention will be described with reference to the drawings. In addition, in the description of each of the following embodiments, the object to be inspected is a steel pipe, and a case where magnetic particle inspection is performed on the inner surface and the outer surface of the steel pipe as inspection objects is taken as an example. However, the present invention is not limited to this form, and it can be used other than steel pipes as long as it is a tubular object made of a ferromagnetic material. In addition, it goes without saying that it can be used even if the inspection surface is only either the inner surface or the outer surface of the object to be inspected.

[0050] figure 1 (a)~ figure 1 (f) is explanatory drawing which shows the state of the magnetic particle flaw detection of the inner surface and the oute...

no. 2 approach

[0079] Next, a second embodiment will be described. In addition, in the description of each of the following embodiments, parts different from those of the first embodiment will be described, and the same parts will be given the same symbols in the drawings to appropriately omit overlapping descriptions.

[0080] Figure 4 (a)~ Figure 4 (f) is explanatory drawing which shows the state of the magnetic particle flaw detection of the inner surface and the outer surface of the steel pipe P using the magnetic particle flaw detection apparatus 100-1 which concerns on this embodiment with time. The main difference between this magnetic particle testing device 100 - 1 and the magnetic particle testing device 100 of the first embodiment is that a spreading device 23 is provided on the magnetizing device 11 and a spreading device 24 is provided on the magnetizing device 12 .

[0081] That is, on the magnetizing device 11, it is provided that the distributing device 23 can be switched...

no. 3 approach

[0095] Next, a third embodiment will be described.

[0096] Figure 5 (a)~ Figure 5 (f) is explanatory drawing which shows the state of the magnetic particle flaw detection of the inner surface and the outer surface of the steel pipe P using the magnetic particle flaw detection apparatus 100-2 of this embodiment with time. The main difference between this magnetic particle flaw detection apparatus 100-2 and the magnetic particle flaw detection apparatus 100-1 of the second embodiment is that the spreading device configuration switching devices 25 and 26 are not provided, so the spreading device 23 provided on the magnetizing device 11 and the The spreading means 24 provided on the magnetizing means 12 are all arranged in fixed positions.

[0097] Next, the state of performing the magnetic particle flaw detection will be described based on the magnetic particle flaw detection apparatus 100-2 of the present embodiment having the above configuration.

[0098] Firstly, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com