Multi-type tap grinding machine

A grinding machine, multi-model technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of non-processing, waste, change of the total length of the tap, etc., and achieve the effect of not easy to fall off, easy to operate, and reasonable to set.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

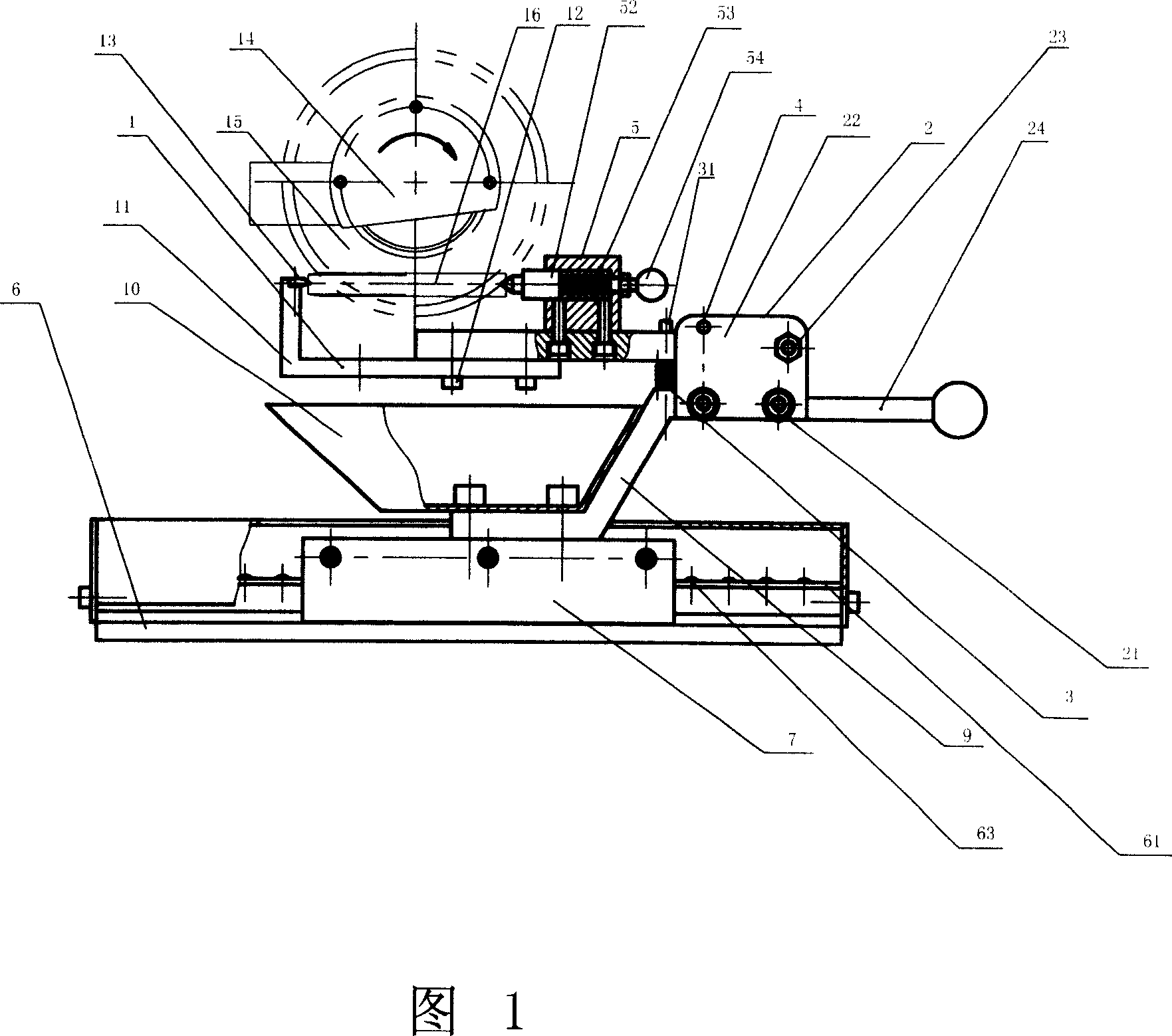

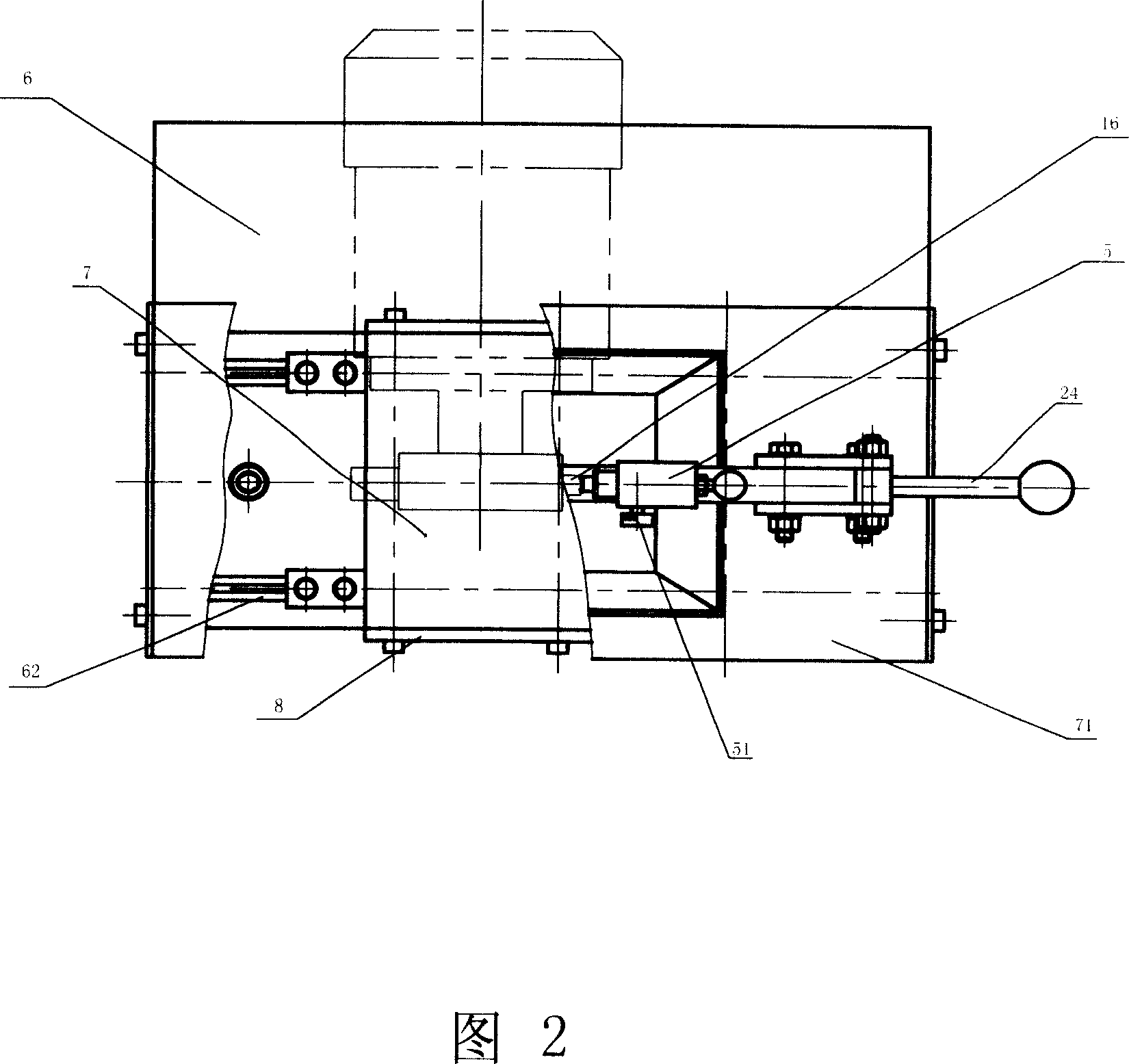

[0018] Embodiment 1: multi-type tap grinding machine, including a bed base 6, two V-shaped steel ball slides 62 are arranged on the bed base 6, and a shelf plate 61 and steel balls 63 are arranged in the V-shaped steel ball slides 62. A slide table 7 is provided above the shaped steel ball slideway 62, and a limit plate 8 is provided on both sides of the slide table 7. The slide table 7 is fixedly connected with a connecting arm 9, the connecting arm 9 is provided with an ash hopper 10, and the afterbody of the connecting arm 9 is provided with There is a handle 24, and the outside of the connection between the two is hinged with a connecting body 2. The connecting body 2 is formed by fixing two identical metal blocks 22 through bolts 21. The connecting body 2 is equipped with a lever arm 1, and the lever arm 1 is formed by 2 The middle of the two metal rods is combined by screws 12. The front end of the lever arm 1 is bent at an angle of 90 degrees and is equipped with a top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com