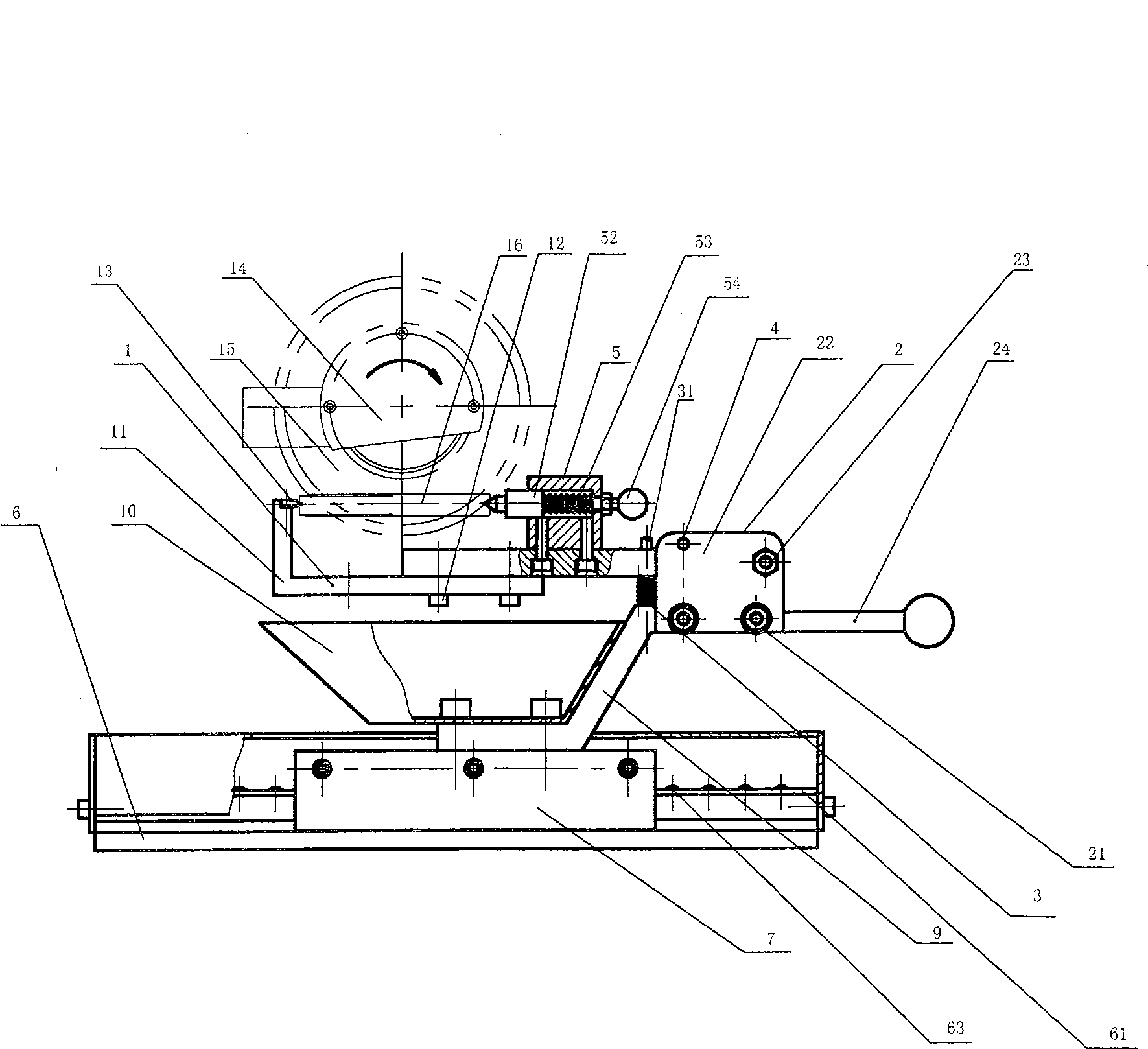

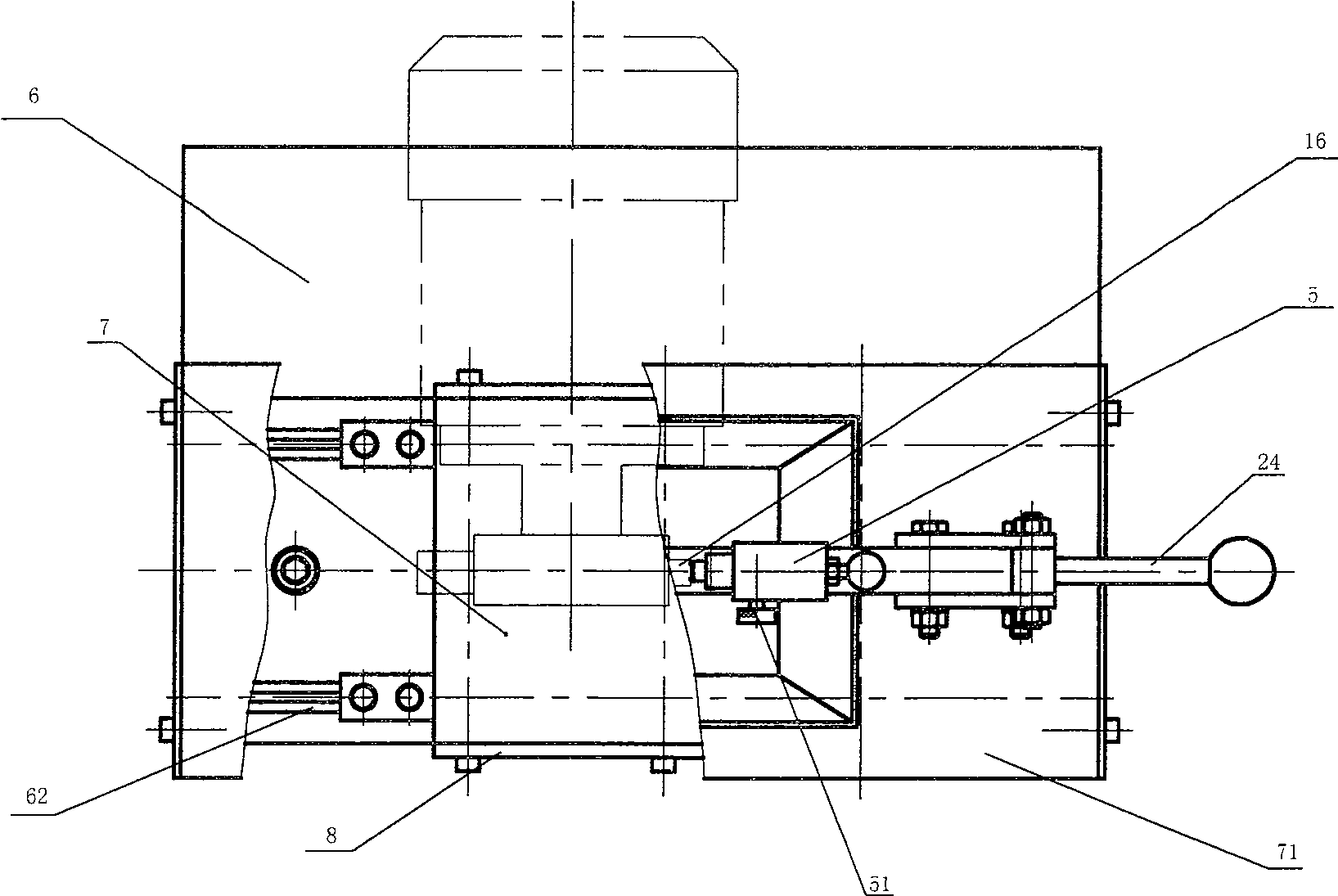

Multi-type tap grinding machine

A grinding machine, multi-model technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of tap total length change, waste, and inability to process, and achieve the effect of reasonable setting, convenient operation, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: multi-type tap grinding machine, including a bed base 6, two V-shaped steel ball slides 62 are arranged on the bed base 6, and a shelf plate 61 and steel balls 63 are arranged in the V-shaped steel ball slides 62. A slide table 7 is provided above the shaped steel ball slideway 62, and a limit plate 8 is provided on both sides of the slide table 7. The slide table 7 is fixedly connected with a connecting arm 9, the connecting arm 9 is provided with an ash hopper 10, and the afterbody of the connecting arm 9 is provided with There is a handle 24, and the outside of the connection between the two is hinged with a connecting body 2. The connecting body 2 is formed by fixing two identical metal blocks 22 through bolts 21. The connecting body 2 is equipped with a lever arm 1, and the lever arm 1 is formed by 2 The middle of the two metal rods is combined by screws 12. The front end of the lever arm 1 is bent at an angle of 90 degrees and is equipped with a top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com