Tire reinforcing triangular combination structure

A combined structure and triangular technology, applied in the reinforcement layer, tire parts, tire edge and other directions of pneumatic tires, can solve the problems of easy heat generation of the bead, low cost performance, empty sub-holes, etc., to improve the bearing performance, The effect of uniform material transition and prevention of wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings.

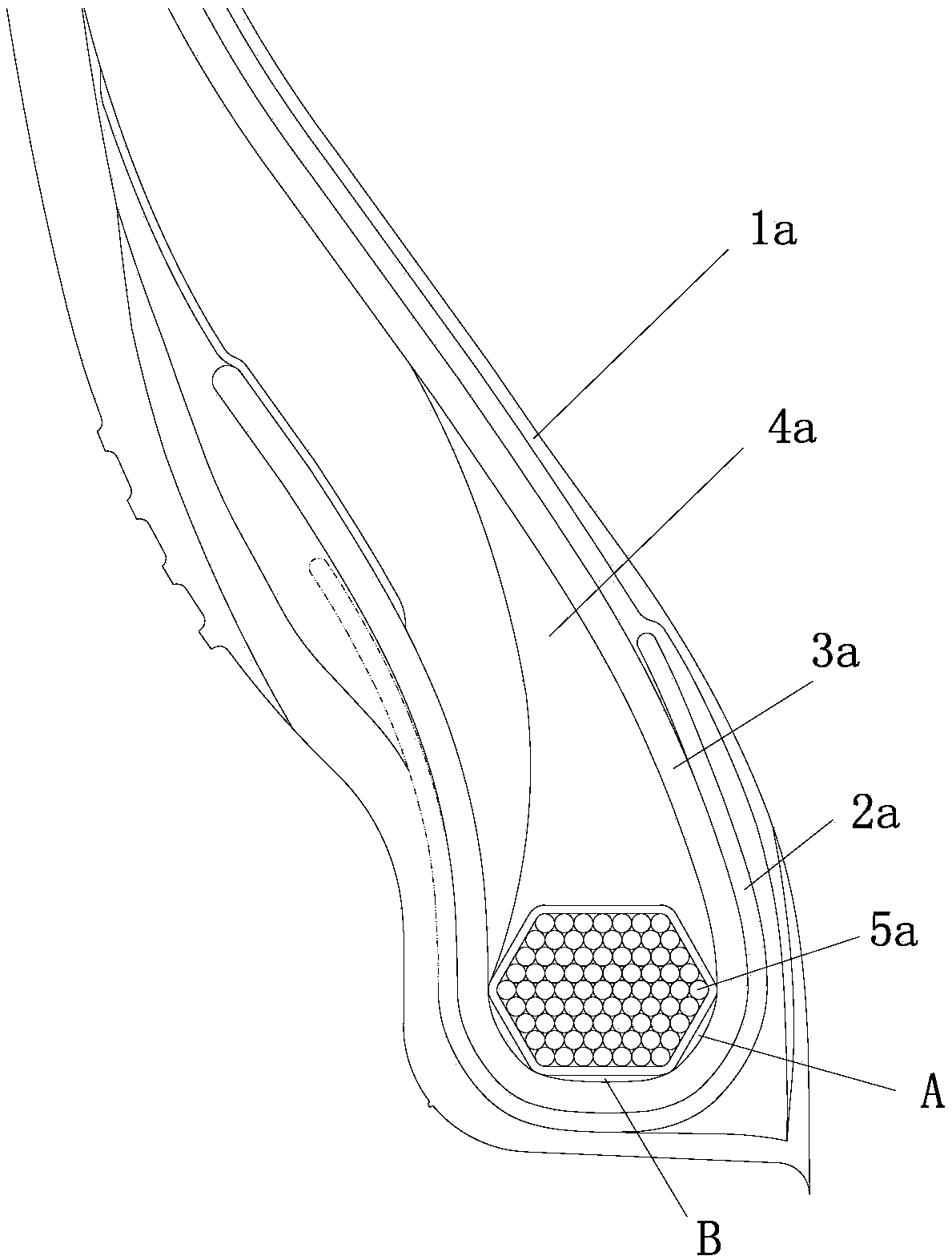

[0022] Such as Picture 1-1 As shown, the bead position of the tire in the prior art is successively the inner liner 1a, the steel wire slit 2a, the carcass 3a, and the triangular assembly 4a (such as Figure 1-2 Shown) and the traveler 5a, due to the high rigidity of the carcass, there is inevitably a void area A and a void area B.

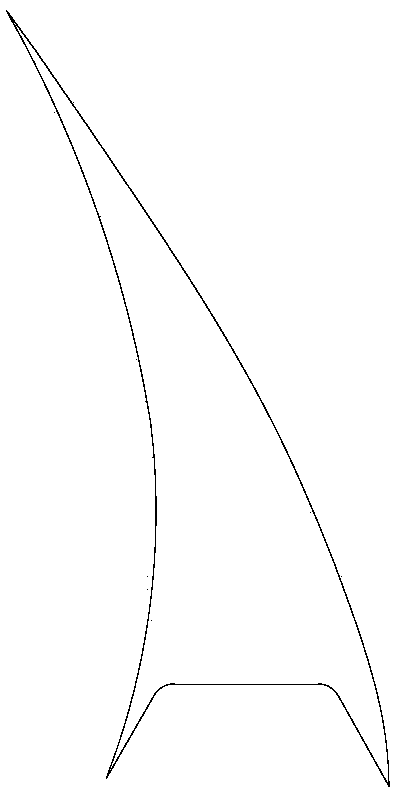

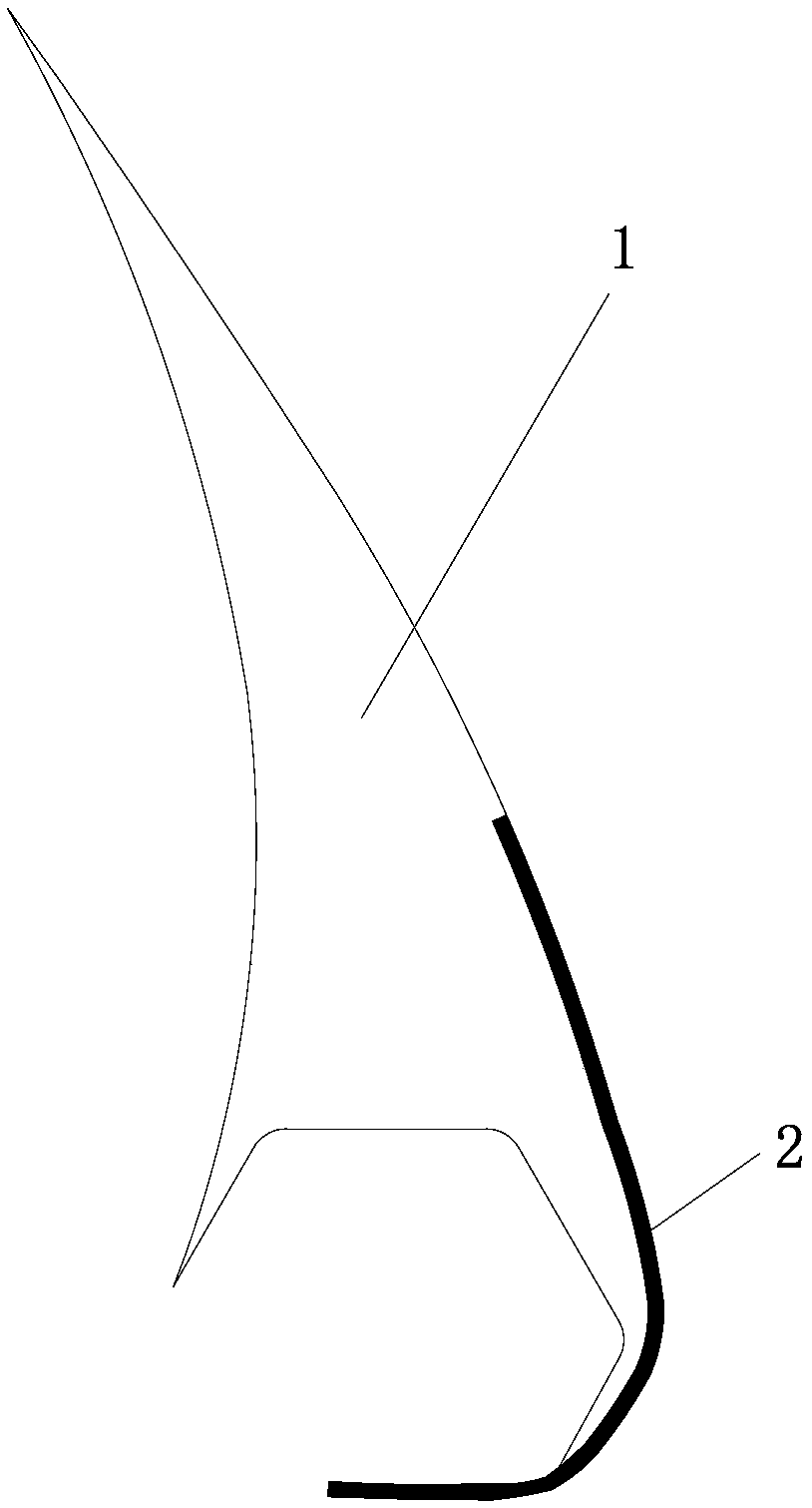

[0023] Such as figure 2 As shown, the tire reinforced triangular combination structure of the present invention includes a triangular part 1 extruded by a triangular mouth plate of a specific shape. Production of butadiene rubber and white carbon black with low heat generation; the main function of the triangular part 1 is to fill the gaps in the corresponding parts and make a uniform transition, so that the heat generation in this area of the tire is lower, the strength is higher, and the fit is better. Good, to prevent the problems of brok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com