Device and method for flaw detection of small crawler-type rails based on three-way ultrasonic diffraction

A flaw detection device, crawler-type technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problem of poor quantitative detection performance, low detection rate, and low efficiency Low and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

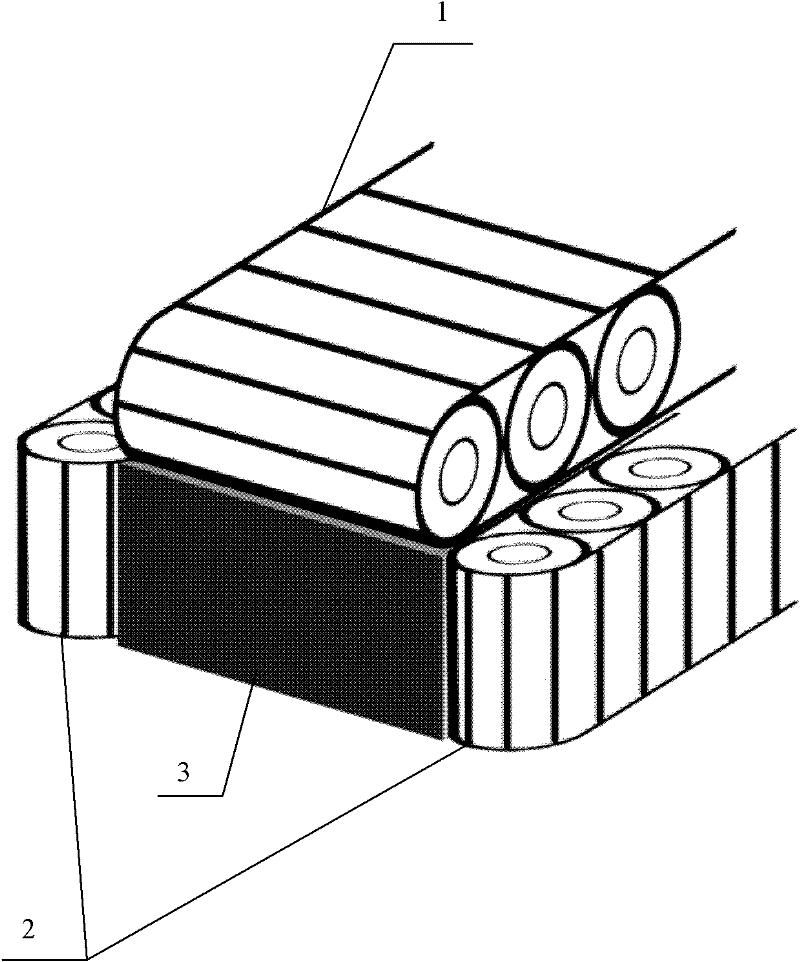

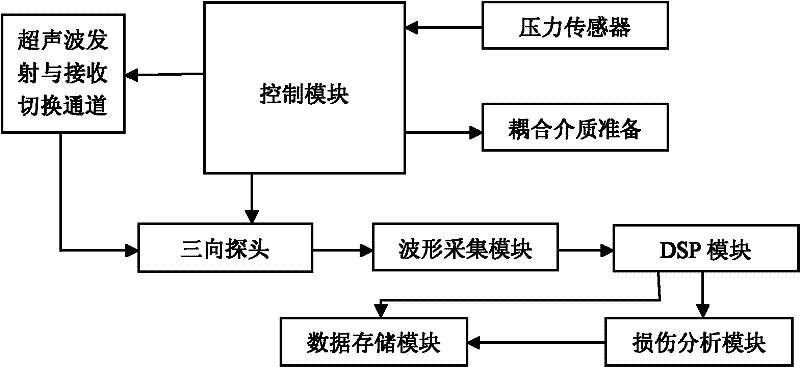

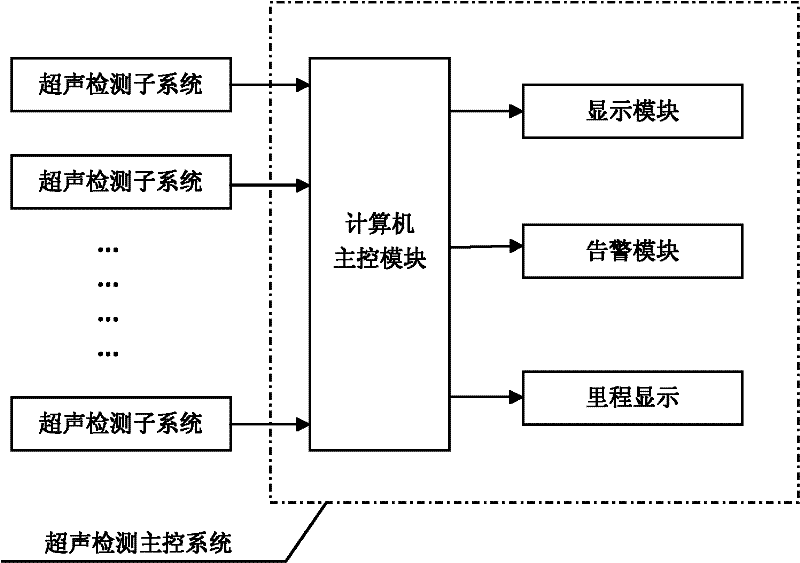

[0051] Such as figure 1 As shown, the three-way crawler driving system of the present invention is composed of three sets of crawlers, wherein the crawler located above the rail 3 is the main crawler 1, and the crawlers on the left and right sides are auxiliary crawlers 2, and the main crawler 1 is responsible for driving the flaw detection trolley March. The three sets of crawlers are embedded with several ultrasonic probes in the direction along the direction of the rail, which are respectively attached to the top of the rail 3 and the left and right sides during detection. According to the length of the track along the rail, the track embedded with the ultrasonic probe is divided into several detection sub-areas (assumed to be N), in which each side of the track in each sub-area is equipped with an ultrasonic probe, because there are 3 groups of tracks, so the division Each sub-area is equipped with 3 ultrasonic probes in three directions. On a section perpendicular to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com