Trolley type automatic ultrasonic flaw-detecting machine with built-in robot for large cylindrical shell section parts

A technology of robots and large cylinders, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and instruments. The effect of improving the efficiency of flaw detection and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

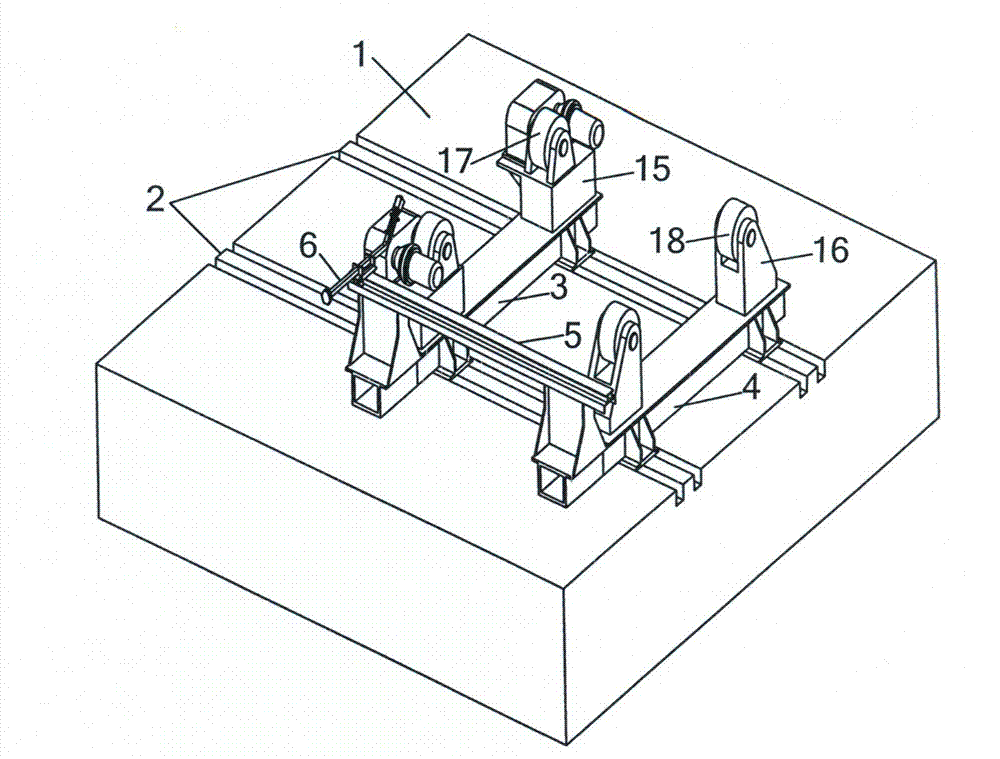

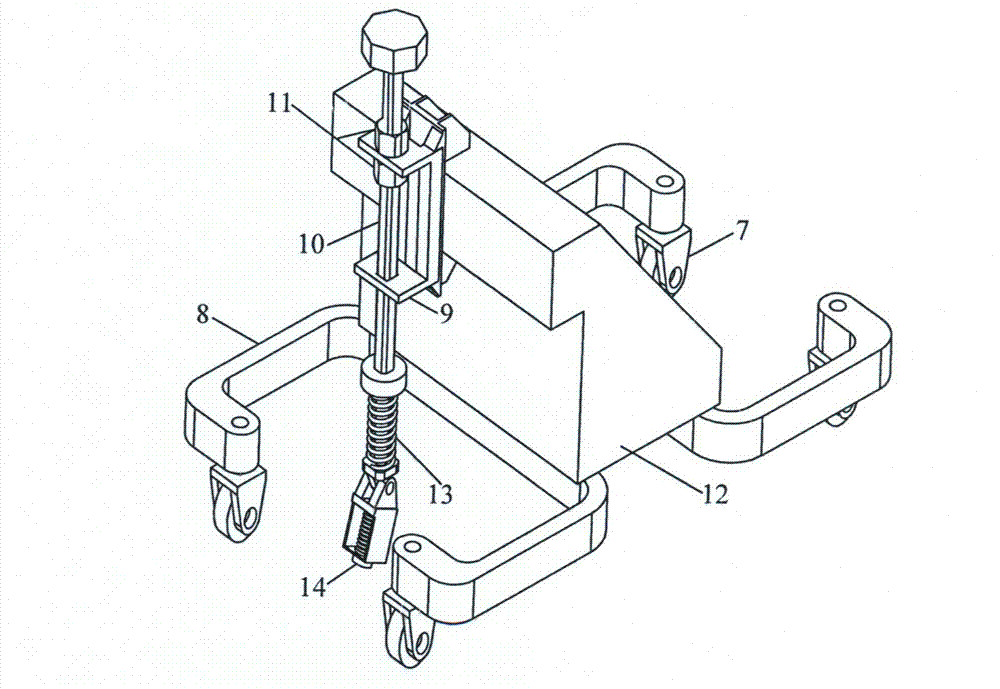

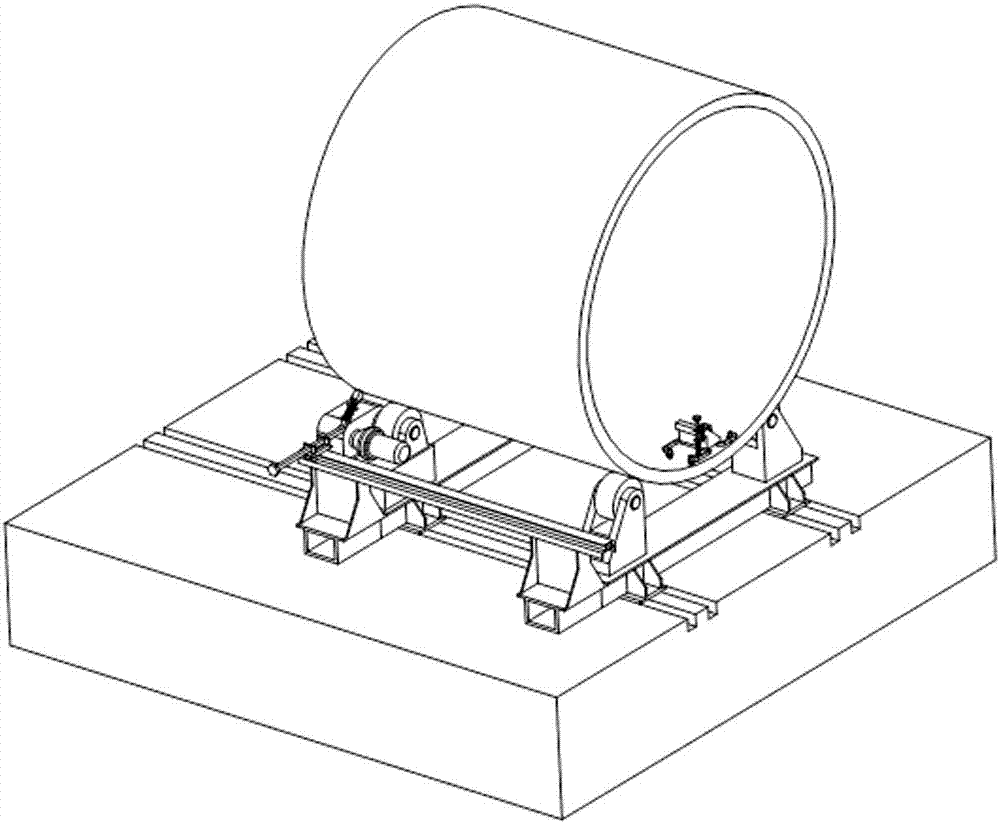

[0017] The present invention will be further described in conjunction with the accompanying drawings and embodiments as follows. Such as figure 1 , 2 As shown, the built-in robot trolley type large-scale automatic ultrasonic flaw detection machine for cylindrical joints of the present invention consists of a working platform, a robot flaw detection trolley and an external flaw detection device.

[0018] The working platform 1 of the present invention is provided with two fixed straight guide rails 2 parallel to each other. On the straight guide rails 2, a driving roller frame beam 3 and a driven roller frame beam 4 are arranged; the driving roller frame beam 3 is fixedly connected to One axial end of the straight guide rail 2 and the other end driven roller frame beam 4 form a movable connection with the guide rail 2, and the position on the straight guide rail 2 can be adjusted according to the length of the cylinder section, and the two ends of the driving roller frame beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com