Weld joint nondestructive testing device for pipeline flaw detection

A non-destructive testing and piping technology, applied in heating devices, spraying devices, using non-combustion exothermic chemical reactions to generate heat, etc., can solve problems such as inability to spray permeate through pipelines, accumulation of impurities inside the device, and affecting detection results, etc. , to achieve scientific and reasonable structure, improve uniformity, and increase utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

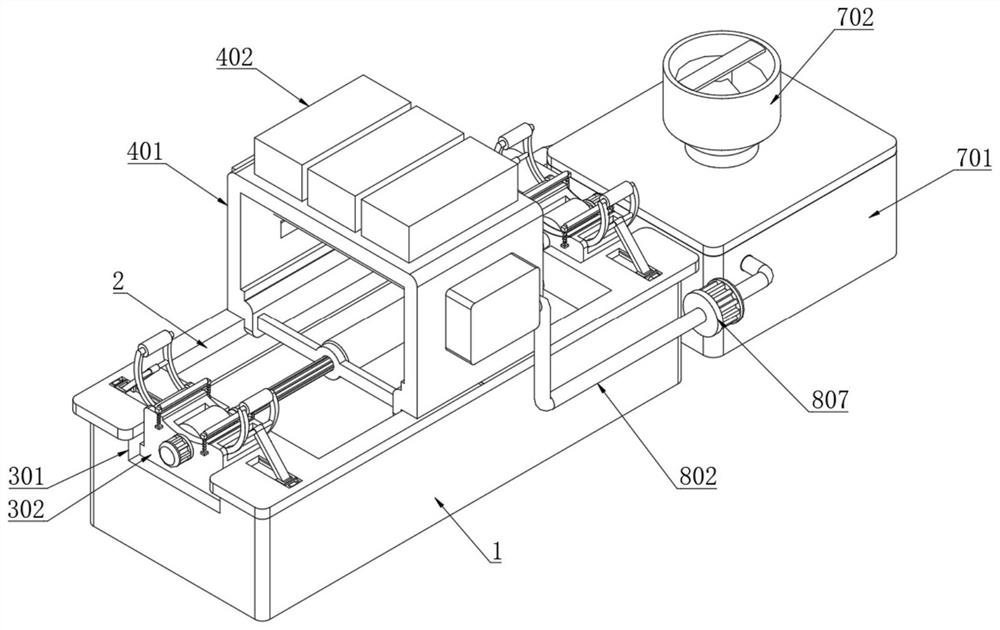

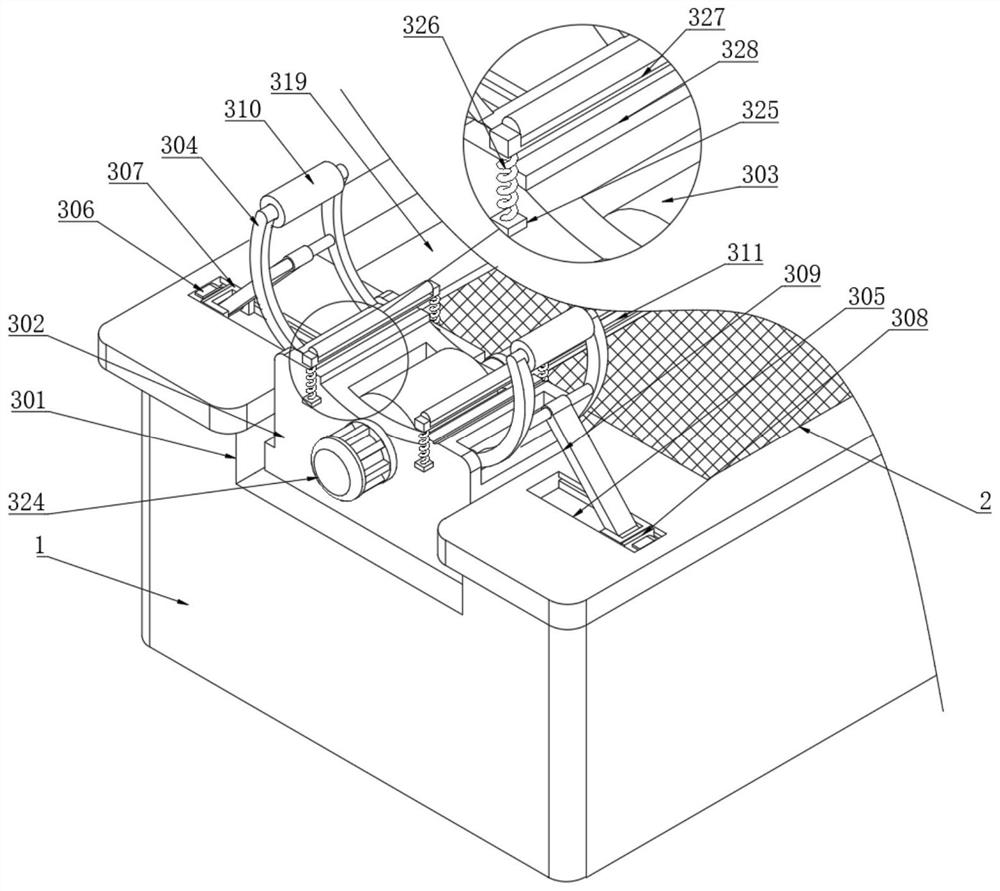

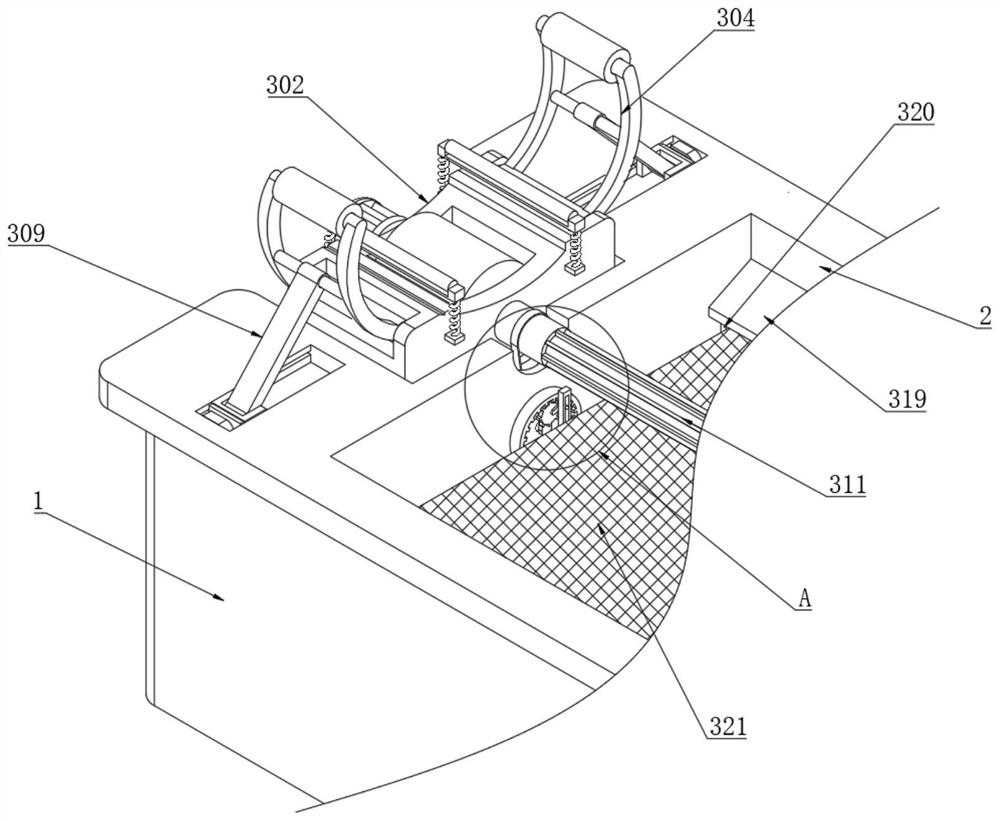

[0040] Example: such as Figure 1-10 As shown, the present invention provides a technical solution based on a weld non-destructive testing device for pipeline flaw detection, including a machine base 1, a liquid storage tank 2 is opened at the middle of the top of the machine base 1, and the inside of the liquid storage tank 2 A waste water discharge mechanism 5 is provided;

[0041] The top of the machine base 1 is symmetrically provided with a limiting and screening mechanism 3 at the positions corresponding to both sides of the liquid storage tank 2;

[0042] A high-efficiency spraying mechanism 4 is arranged at the top of the base 1 corresponding to the top of the liquid storage tank 2;

[0043] The limit and screening mechanism 3 includes an embedded groove 301, a support seat 302, a support wheel 303, a clamping force arm 304, a chute 305, an electromagnet 306, a slider 307, a magnetic strip 308, a push plate 309, and a limit roller 310 , rotating shaft 311, notch 312,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com