High-efficiency steel pipe flaw detection device

A technology for flaw detection devices and steel pipes, applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc., can solve the problems of restricting the detection speed of steel pipe eddy current flaw detection, slow running of steel pipe eddy current flaw detection lines, and low efficiency, etc., to achieve High flaw detection efficiency, reduced failure rate, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

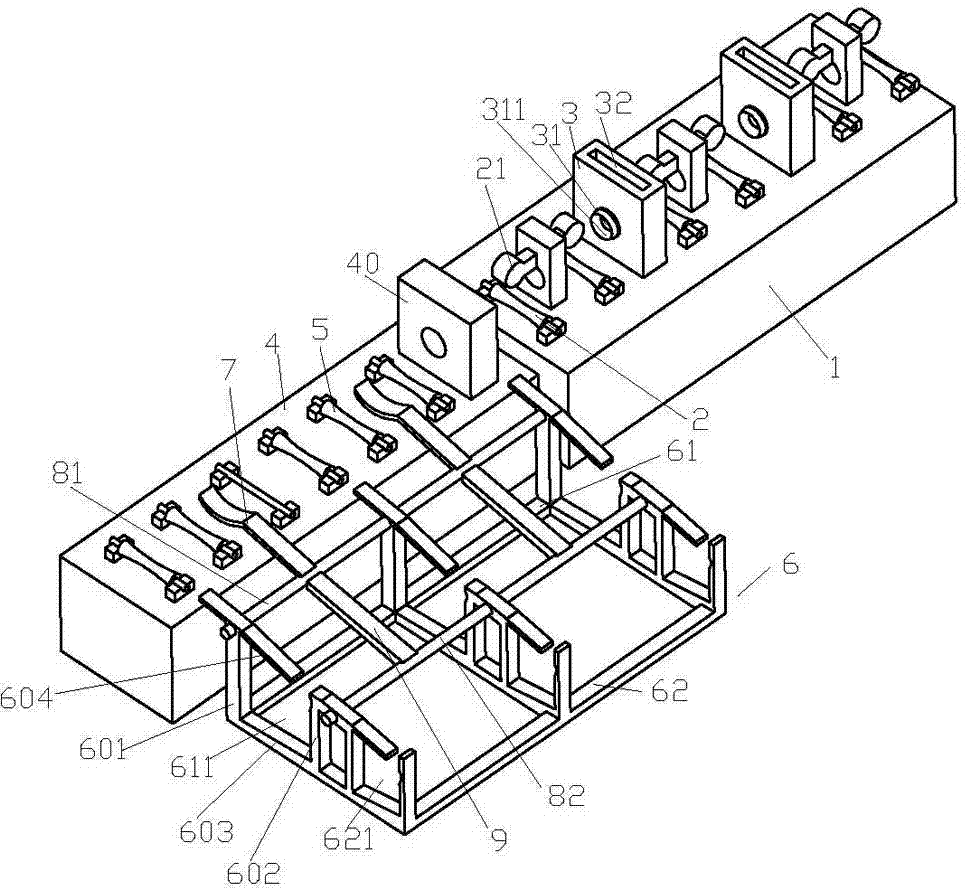

[0020] Example 1, such as figure 1 As shown, a high-efficiency steel pipe flaw detection device includes a detection frame 1, a row of conveying wheels 2 are arranged on the detection frame 1, and a liftable guide roller 21 is arranged on the conveying wheels 2, and the structure of the lifting frame can be adopted to make The guide roller 21 can be raised and lowered and locked. A flaw detection device is installed in the conveying direction of the conveying wheel 2. The flaw detection device includes a flaw detector and a fixed box 3 for placing the flaw detector and guiding the steel pipe. The perforation 31 passed through, and the limit groove 32 for placing the flaw detector, the position of the perforation 31 of the fixed box 3 is provided with a steel pipe guide ring 311, and the steel pipe guide ring 311 is trumpet-shaped near the outer end of the fixed box 3, and the flaw detector can be used For the ultrasonic flaw detector and the eddy current flaw detector, ther...

Embodiment 2

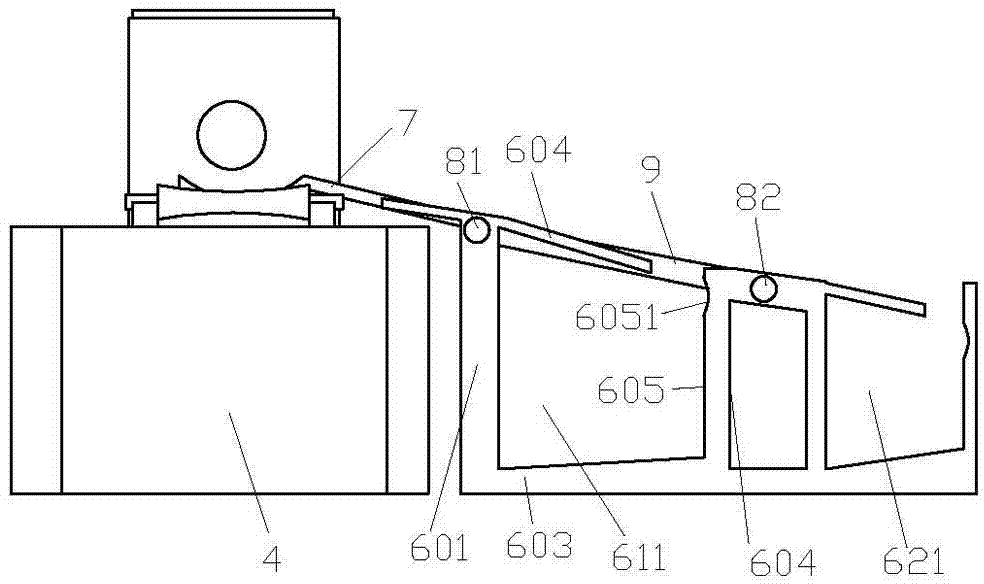

[0022] Example 2, such as figure 2 As shown, the difference between it and Embodiment 1 is that a buffer wall 605 is provided on the side of the far column 602 of the genuine product frame 611 facing the sliding guide column 604 of the genuine product frame 611, and a circular arc is provided on the buffer wall 605 on the side where the steel pipe enters. shaped groove 6051, and the bottom column 603 is inclined from the far column 602 to the near column 601.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com