Stamping product collection device with folding device and folding method

The technology of a collecting device and a pressing device is applied in the field of stamping product collecting device with a stacking device, which can solve the problems of unfavorable automatic production operation, low production efficiency, waste of time and energy of workers, etc., and achieves convenient collection and stacking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

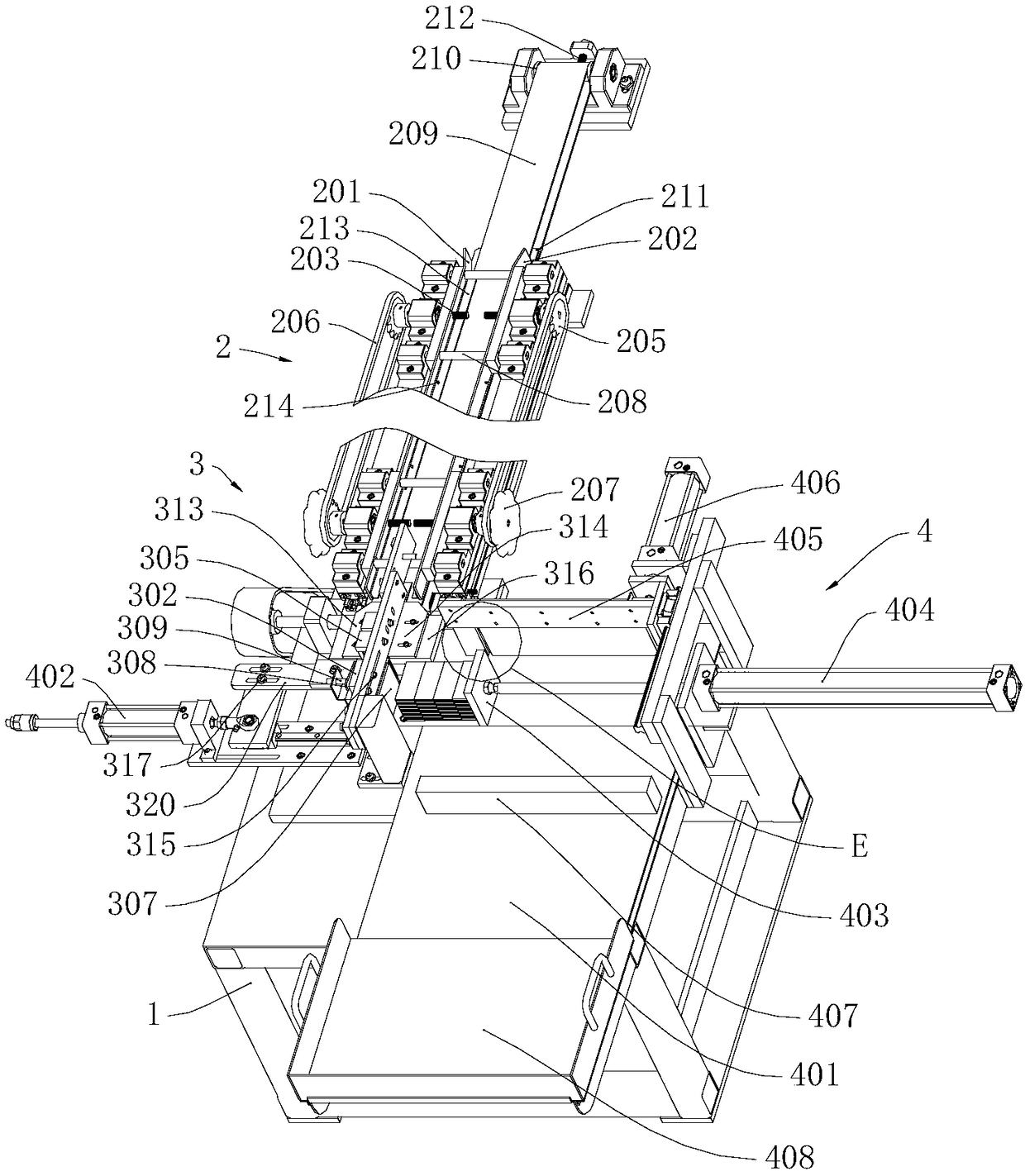

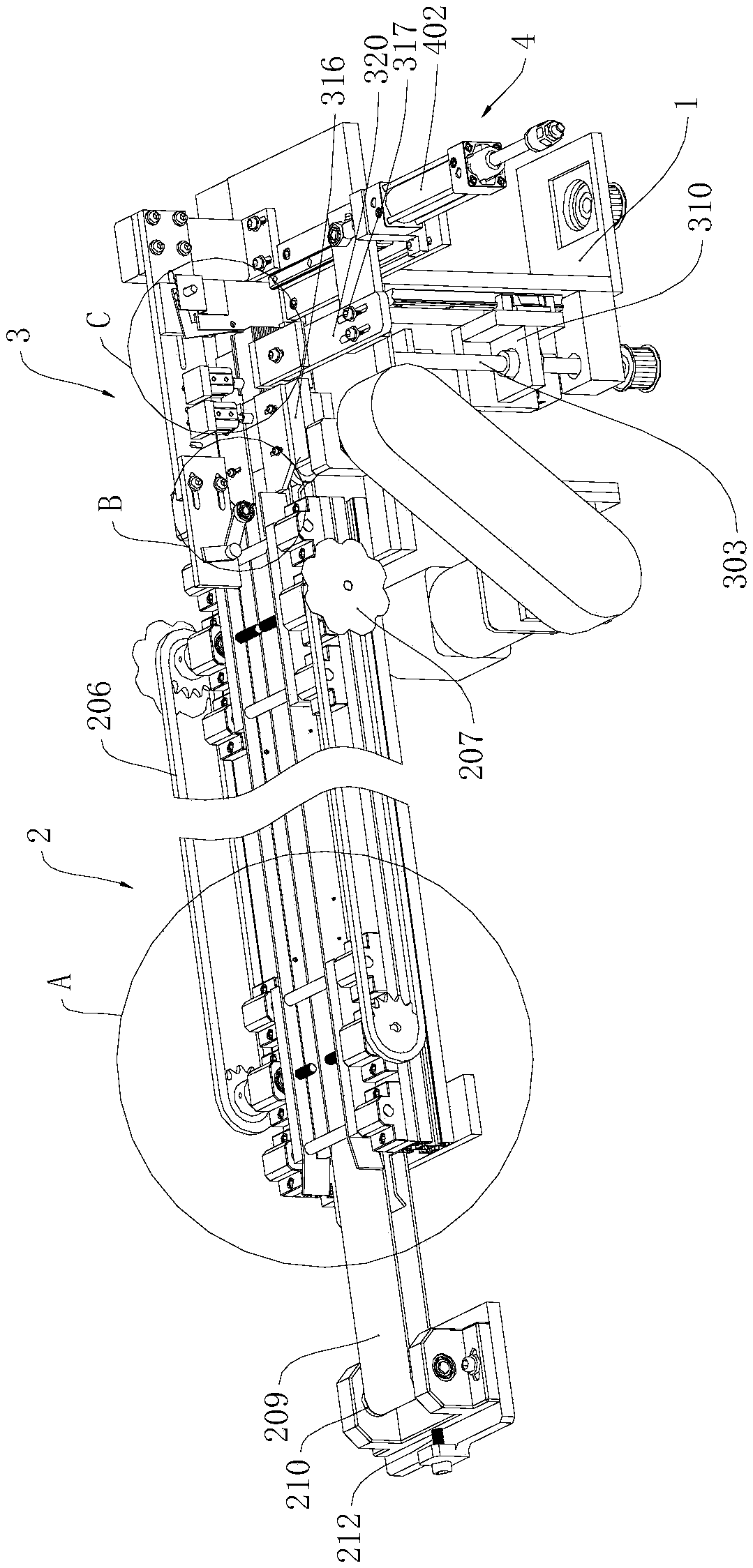

[0102]The stamping product folding method of the present embodiment adopts the aforementioned stamping product collecting device, sets the height value of the first drop of the stacking platform 301; sets the first interval time for the downward movement of the stacking platform 301; initial state: the stacking platform 301 The upper surface is not higher than the conveying surface of the conveying device 2; the conveying device 2 is running: the conveying device 2 is running to convey stamped products, and the stamped products fall onto the stacking platform 301 when they are passed to the top of the stacking platform 301; the stacking platform 301 moves down : When the time from the last downward movement of the stacking platform 301 reaches the first interval time, the first lifting and holding device drives the stacking platform 301 to move down by a height value. When the stamping machine stamps and produces the same batch of stamped products, the stamping frequency and th...

Embodiment 2

[0104] The stamping product folding method of this embodiment adopts the aforementioned automatic folding device for stamping products, and sets the height value of the first drop of the stacking platform 301; sets the first interval time for the downward movement of the stacking platform 301; sets the pressing device The second interval of pressing materials; initial state: the upper surface of the stacking platform 301 is not higher than the conveying surface of the conveying device 2; the conveying device 2 is running: the conveying device 2 is running to transmit stamped products, and the stamped products are passed to the stacking platform 301 Pressing device pressing: when the time from the last pressing of the pressing device reaches the second interval, the pressing mechanism 304 touches the stamped product on the stacking platform 301 once. Moving down of the stacking platform 301: when the time from the last downward movement of the stacking platform 301 reaches the f...

Embodiment 3

[0106] The stamping product folding method of this embodiment adopts the aforementioned automatic folding device for stamping products, and sets the height value of the first drop of the stacking platform 301; sets the stacking amount of the first preset interval; sets the stacking amount of the second preset interval Material volume; initial state: the stacking platform 301 is not higher than the connection table 316; the transmission device 2 is running: the transmission device 2 is running to transmit the stamped products, and the stamped products are transmitted to the stacking platform 301 to touch the incoming material detection device; the pressing device presses the material : When the incoming material detection device detects that the material is pressed last time from the pressing device, and the number of stacked materials on the stacking platform 301 reaches the second preset interval stacking amount, the pressing mechanism 304 touches the stamping on the stacking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com