A kind of processing technology of environment-friendly wood

A processing technology and wood technology, applied in the field of environmentally friendly wood processing technology, can solve the problems affecting the environmental protection of wood, environmental hazards, etc., and achieve the effect of reducing the probability of dust explosion, reducing odor, and improving efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

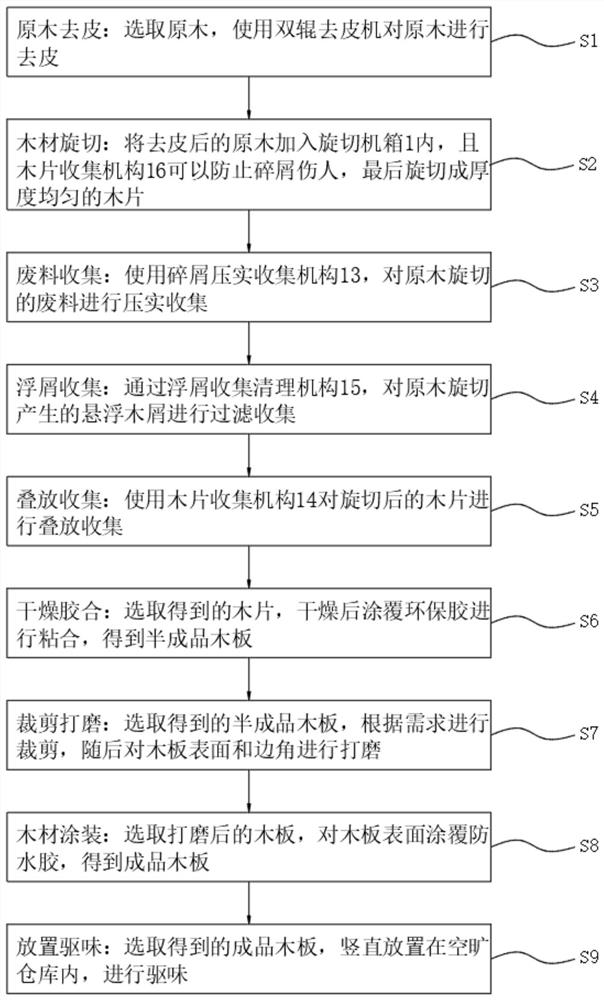

[0045] Embodiment 1: as figure 1 As shown, the present invention provides technical scheme, a kind of processing technology of environment-friendly timber, comprises the steps:

[0046] S1, log peeling: select the log, and use a double-roller peeling machine to peel the log;

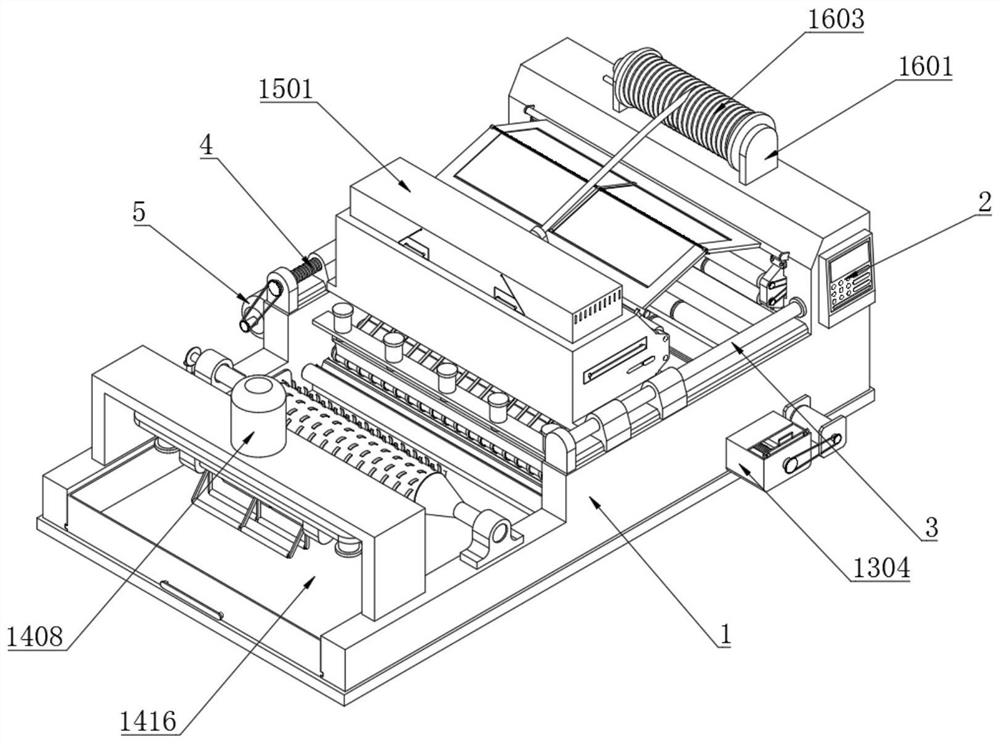

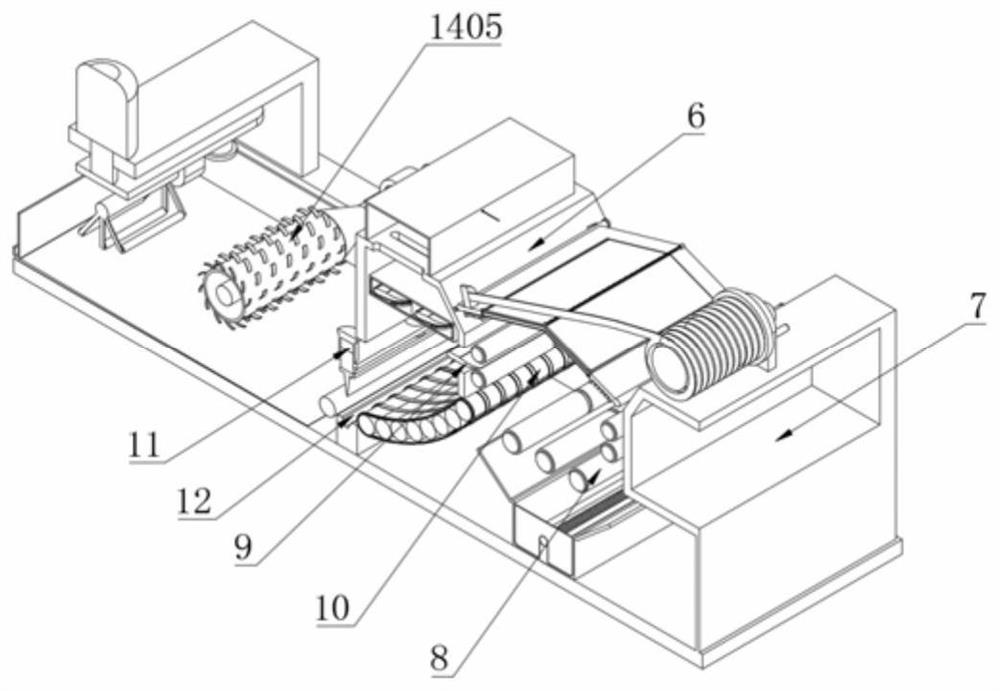

[0047] S2. Wood rotary cutting: add the peeled logs into the rotary cutting machine 1, and the wood chip collection mechanism 16 can prevent debris from hurting people, and finally rotary cut wood chips with uniform thickness;

[0048] S3. Waste collection: use the debris compaction collection mechanism 13 to compact and collect the waste from rotary cutting of logs;

[0049] S4. Floating debris collection: through the floating debris collection and cleaning mechanism 15, the suspended sawdust generated by log rotary cutting is filtered and collected;

[0050] S5, stacking and collecting: use the wood chip collecting mechanism 14 to stack and collect the rotary cut wood chips;

[0051] S6. Drying and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com