Performance test device for water immersion focusing probe and test method thereof

A testing device, water immersion focusing technology, applied in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problems of inability to guarantee the qualified performance of the supplied probes, lack of supervision by the probe manufacturer, and high hardware requirements. , to achieve the effect of improving flaw detection efficiency and quantitative accuracy, improving sensitivity uniformity, and improving coupling conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

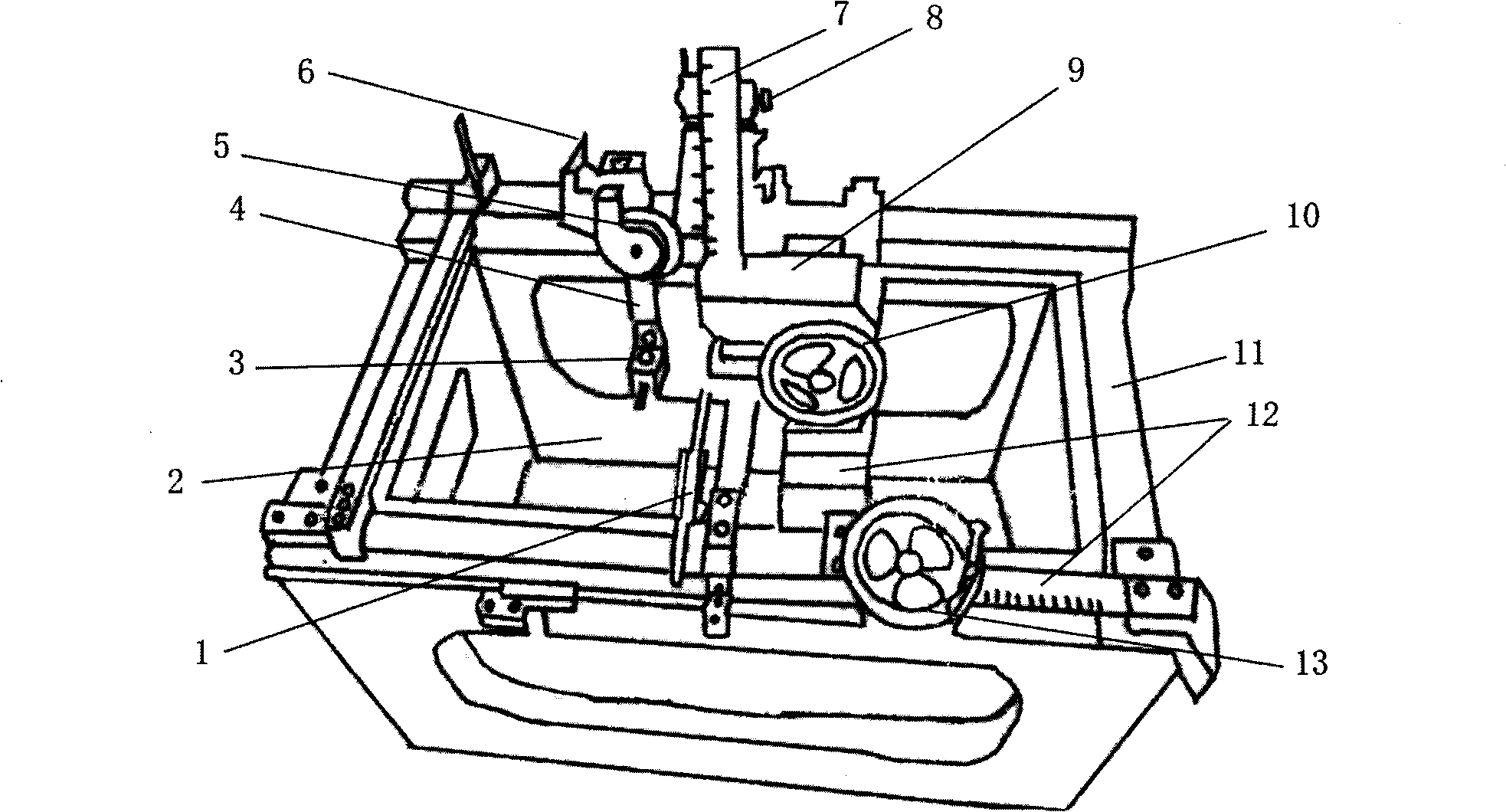

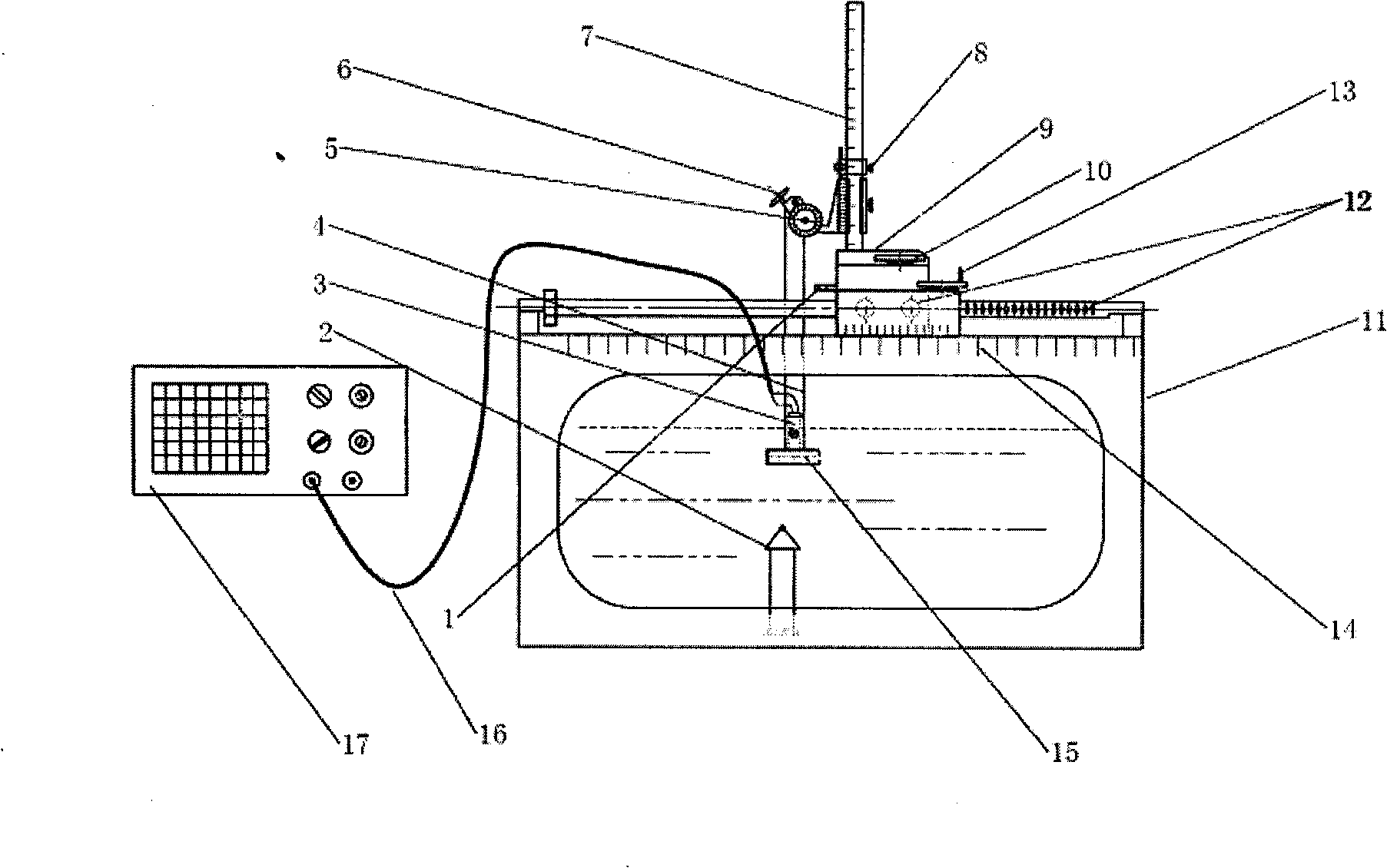

[0082] The water immersion focusing probe performance test device of the present invention is obtained, the test device includes a test device frame body and an ultrasonic flaw detector placed in a water tank, and the test device also includes: movably arranged on the test device frame body 1. A probe mounting seat, a probe clamping device for fixing the probe, a three-dimensional guiding adjustment device that can be movably arranged on the frame body of the test device, and can make the probe move in three dimensions along the X-axis, Y-axis, and Z-axis. Installed on the X-axis, Y-axis, and Z-axis respectively, corresponding to the three-dimensional movement of the probe on the X-axis, Y-axis, and Z-axis, the vernier calipers used for real-time measurement and determination of the position and position change of the ultrasonic probe are set on the test device On the frame body, a reference reflection seat corresponding to the above-mentioned probe fixing seat, and a steel bal...

Embodiment 2

[0093] Focus probe focal length test

[0094] When testing the focal length of the focusing probe, the instrument suppression is set to 0, the compensation is turned off, the gain knob is set above 80% of the adjustment amount, and the attenuator has a certain adjustable amount, generally 30-40dB. Then turn (13) the X-axis adjuster of the probe in the accompanying drawings, so that the probe moves along the direction of the X-axis (there is a reference reflection seat below) along with the three-dimensional guide. Move the probe to the top of the reference reflection seat (3), find the highest point of the reflected echo signal, and adjust the attenuator to make the echo signal reach 80% of the height displayed on the oscilloscope.

[0095] Turn the probe angle adjuster (5) with an angle indication in the X direction to observe whether the sound beam of the probe is incident vertically. If the sound beam of the probe is incident vertically at this time, then when the probe ang...

Embodiment 3

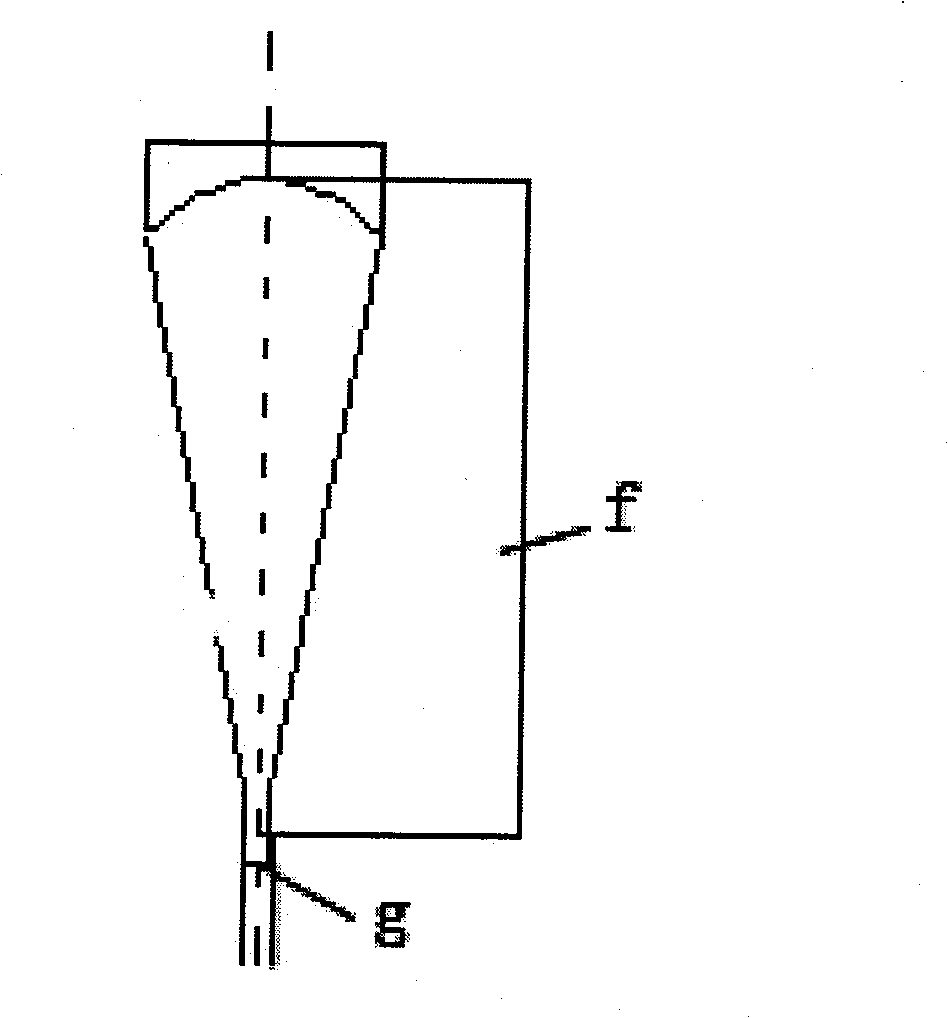

[0101] Probe Beam Width Test

[0102] When testing the beam width of the probe, set the instrument suppression to 0, turn off the compensation, set the gain knob to more than 80% of the adjustment amount, and leave a certain adjustable amount for the attenuator, such as 40dB.

[0103] Then turn the X-axis adjuster of the probe (13) in the attached drawing to make the probe move along the X-axis direction with the three-dimensional guide device, move the probe to the top of the reference reflection seat (3), find the highest point of the reflected echo signal, and adjust the attenuation Make the echo signal reach 80% of the height displayed on the oscilloscope.

[0104] Turn the probe angle adjuster (5) with angle indication in the X direction to observe whether the sound beam of the probe is incident vertically. If the sound beam of the probe is incident vertically at this time, adjust (5) and the reflected signal will drop from 80% of the height. If The probe does not reach ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com