Patents

Literature

119results about How to "High degree of detection automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

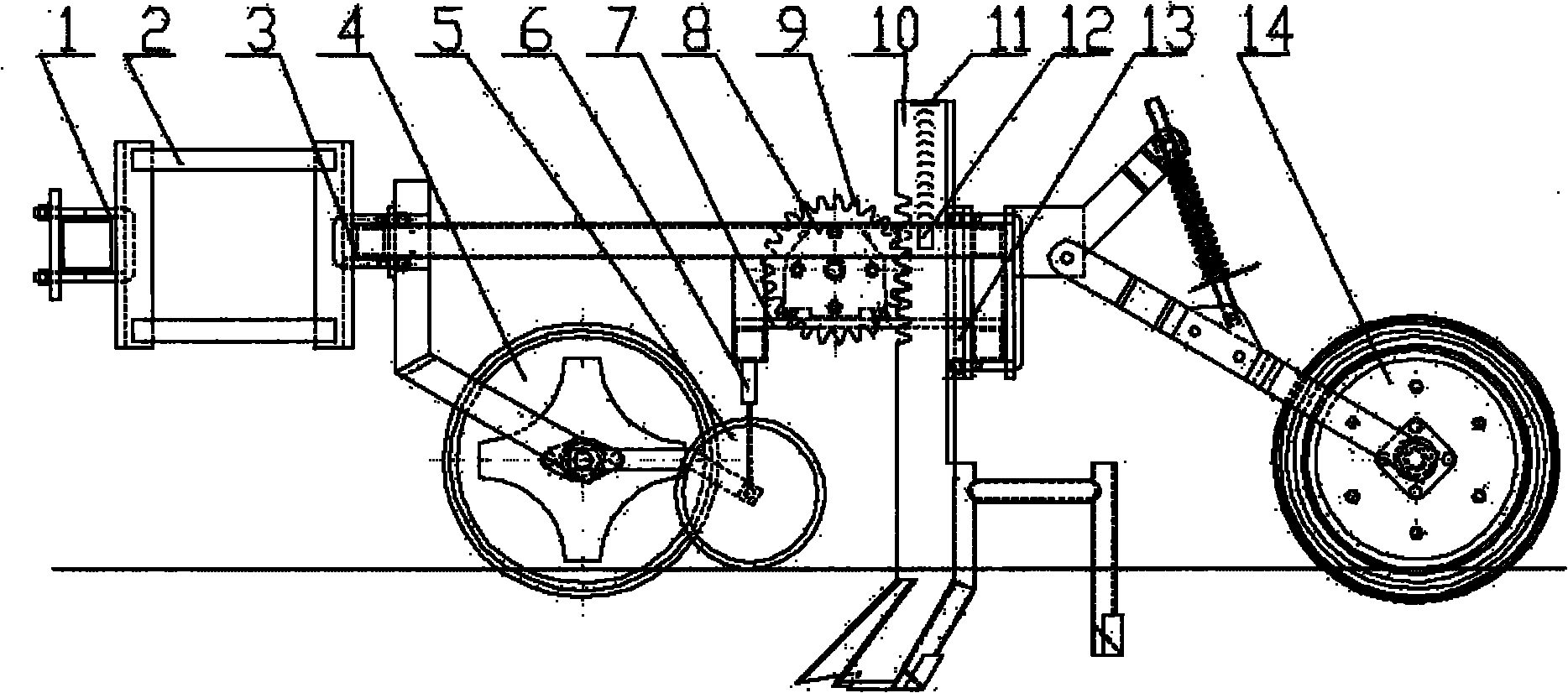

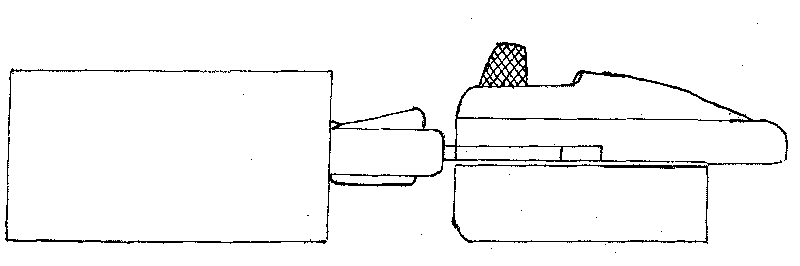

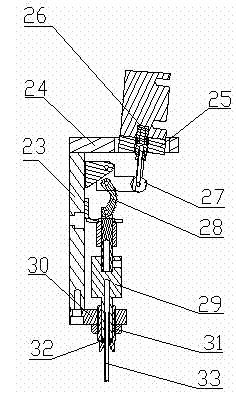

Adjusting device used for sowing depth automatic control system

InactiveCN101785386AImprove germination ratePromote growthMeasurement devicesPlantingAutomatic controlAgricultural engineering

The invention relates to the technical field of agricultural machinery, in particular to an adjusting device used for a sowing depth automatic control system. A small frame is connected with a large frame through a four-bar linkage; a small land wheel is articulated on a wheel axle of a large land wheel and can freely float following the actual land surface relative to the small frame; a detection unit real-timely measures the distance of the small frame relative to the ground and the distance of a furrow opener relative to the small frame; two detected feedback signals are sent to a control part; the control part transfers the information to a hydraulic system after processing, controls a proportional reversing valve to operate and controls the reversion of an output shaft of a hydraulic motor; and an actuating mechanism drives a gear to rotate under the action of the output shaft of the hydraulic motor to realize the up-and-down movement of a slide block at the rear side of a shovel handle of the furrow opener along a guide rail and real-timely control and adjust the sowing depth. The device can realize real-time control and adjustment on the furrow opening depth, has high detection precision and high degree of automation, can improve the germination rate, promotes the crop growth and increases the crop yield.

Owner:CHINA AGRI UNIV

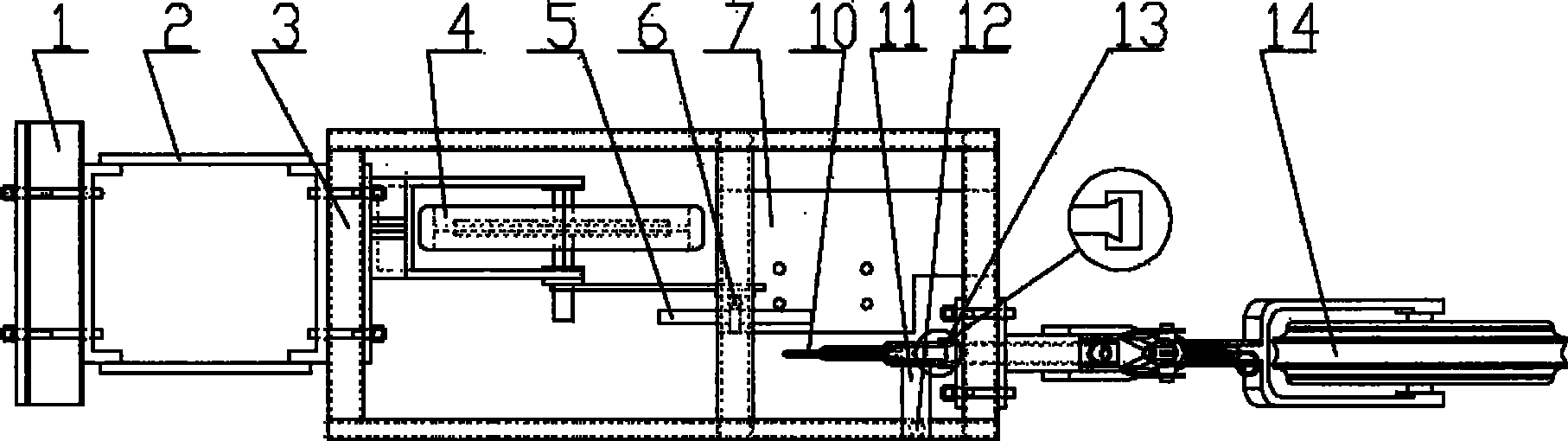

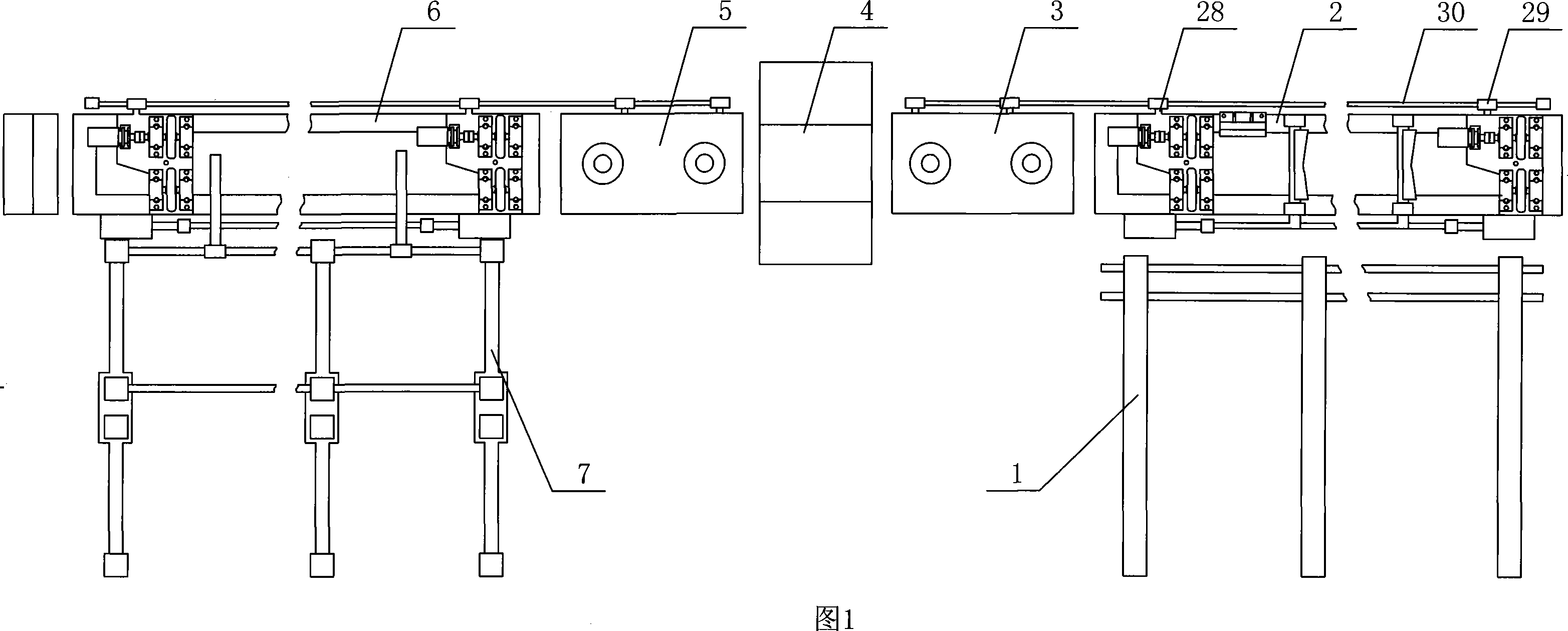

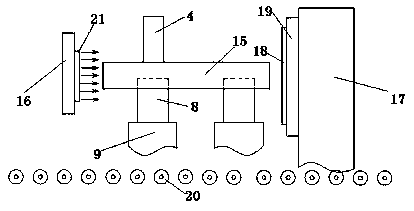

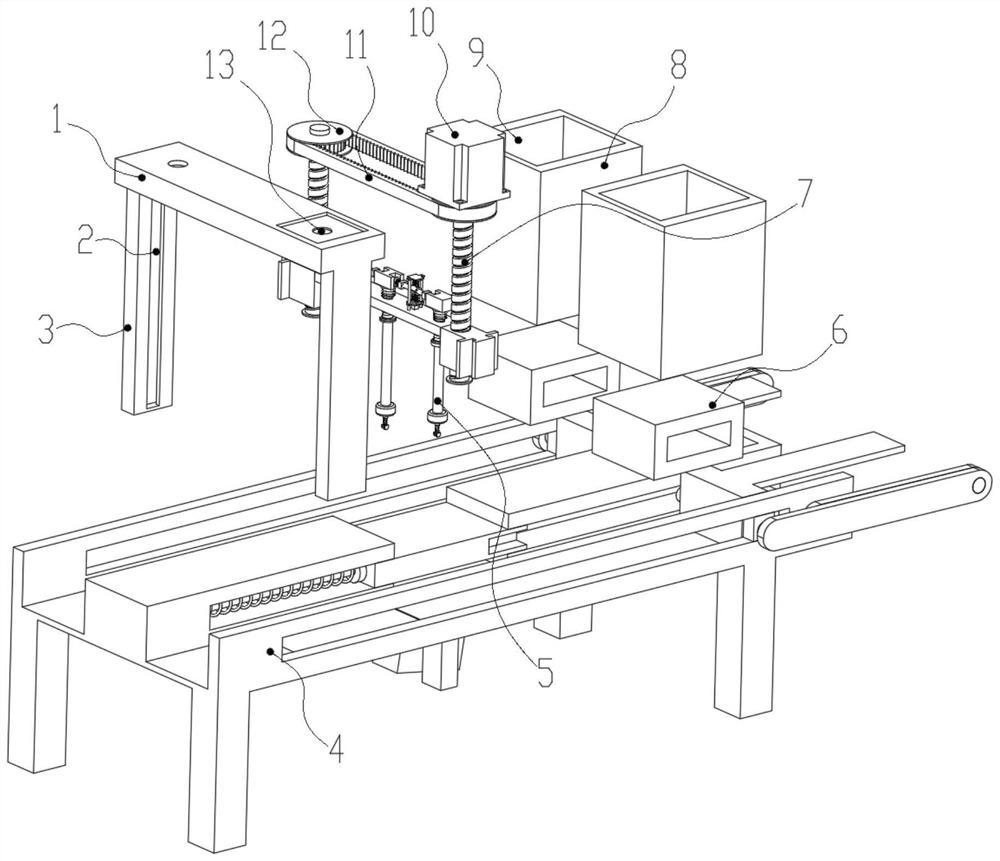

Eddy current inspection equipment

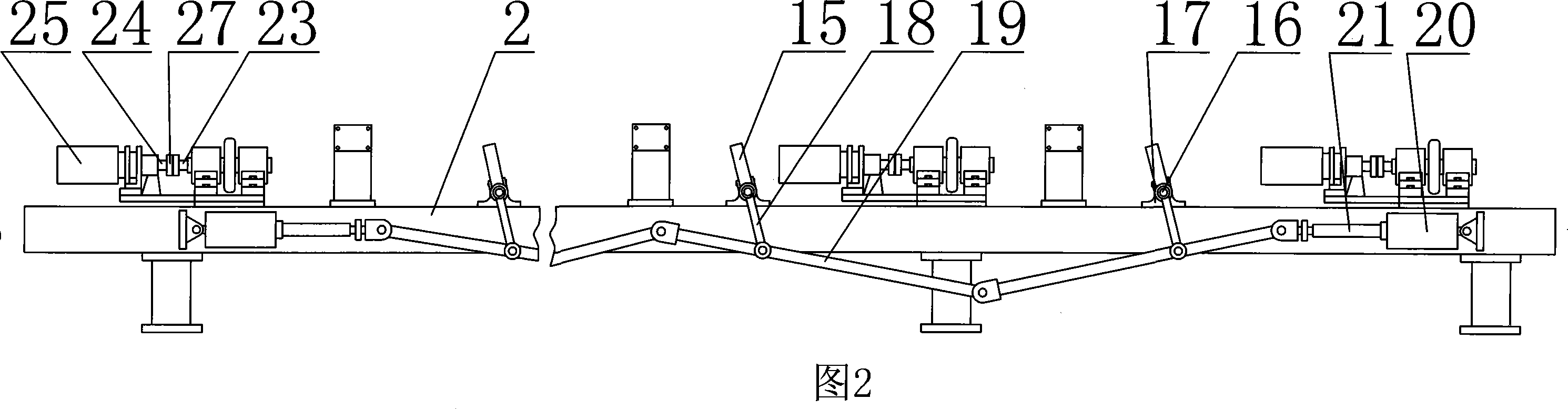

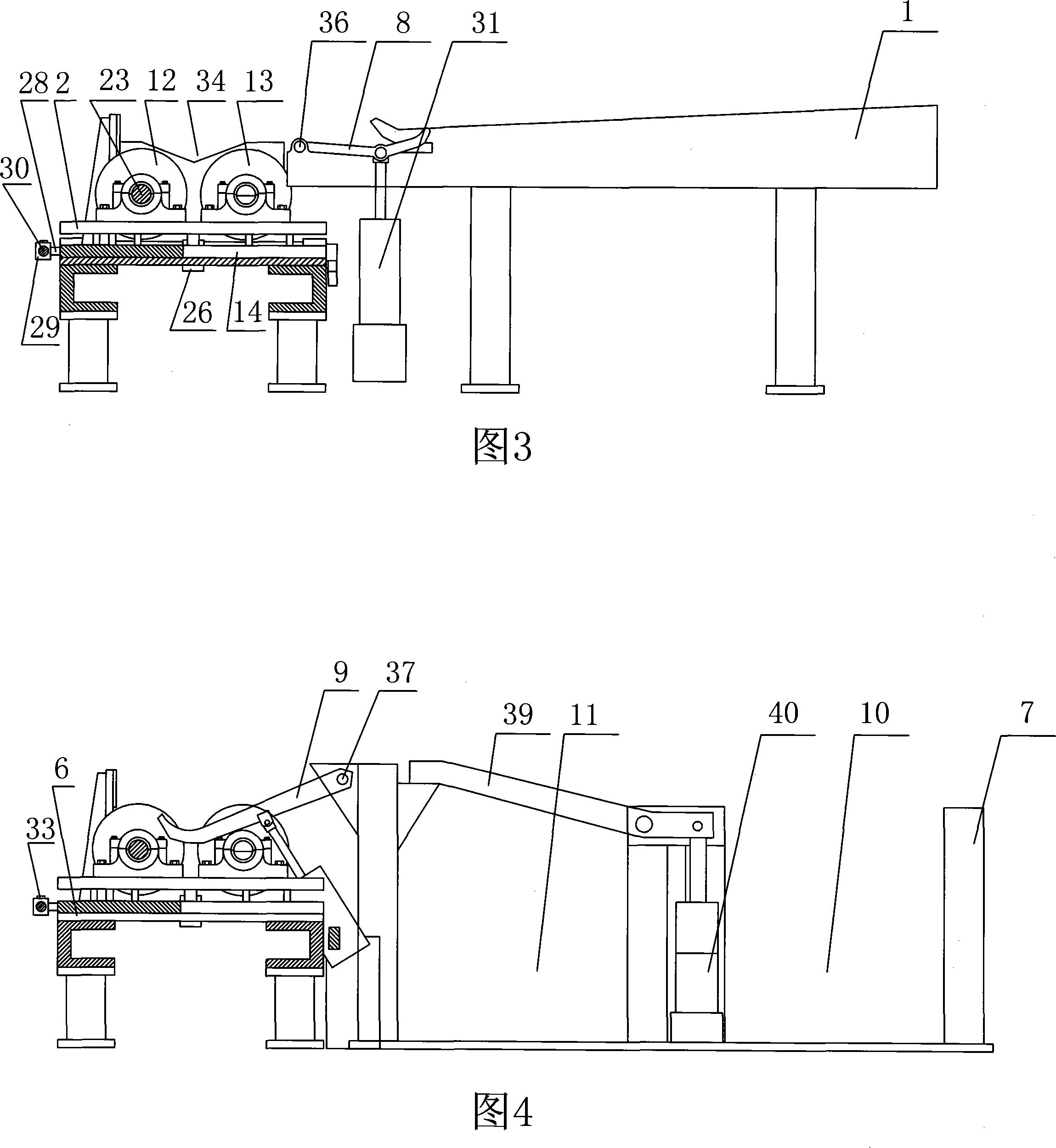

InactiveCN101241108AEasy to operateComprehensive flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesSortingEddy currentMaterial resources

The present invention provides an eddy-current inspector including ultrasonic flaw detector, eddy current detector and computer, whose structure comprises of feeding rack, feeding orbit, pressing wheel mechanism, testing mainframe, blanking orbit and blanking rack, feeding orbit, pressing wheel mechanism, testing mainframe, pressing wheel mechanism and blanking orbit are connected in turn, feeding rack and blanking rack are set on one side of feeding orbit and blanking orbit respectively. The eddy-current inspector of present invention has merits of reasonable design and simply operation, and saves a great deal manpower and material resources, so it has a well widely use value.

Owner:山东济宁模具厂

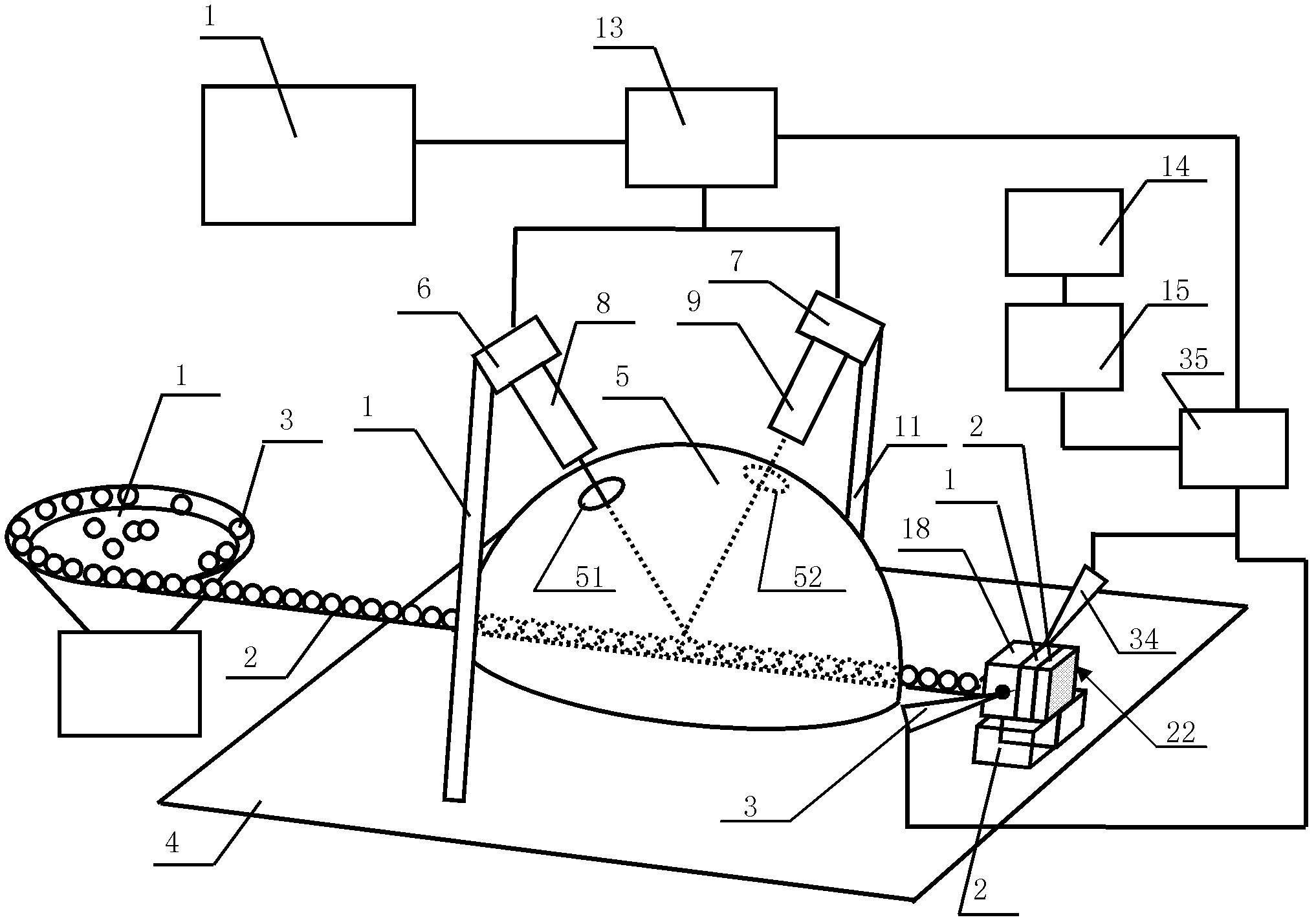

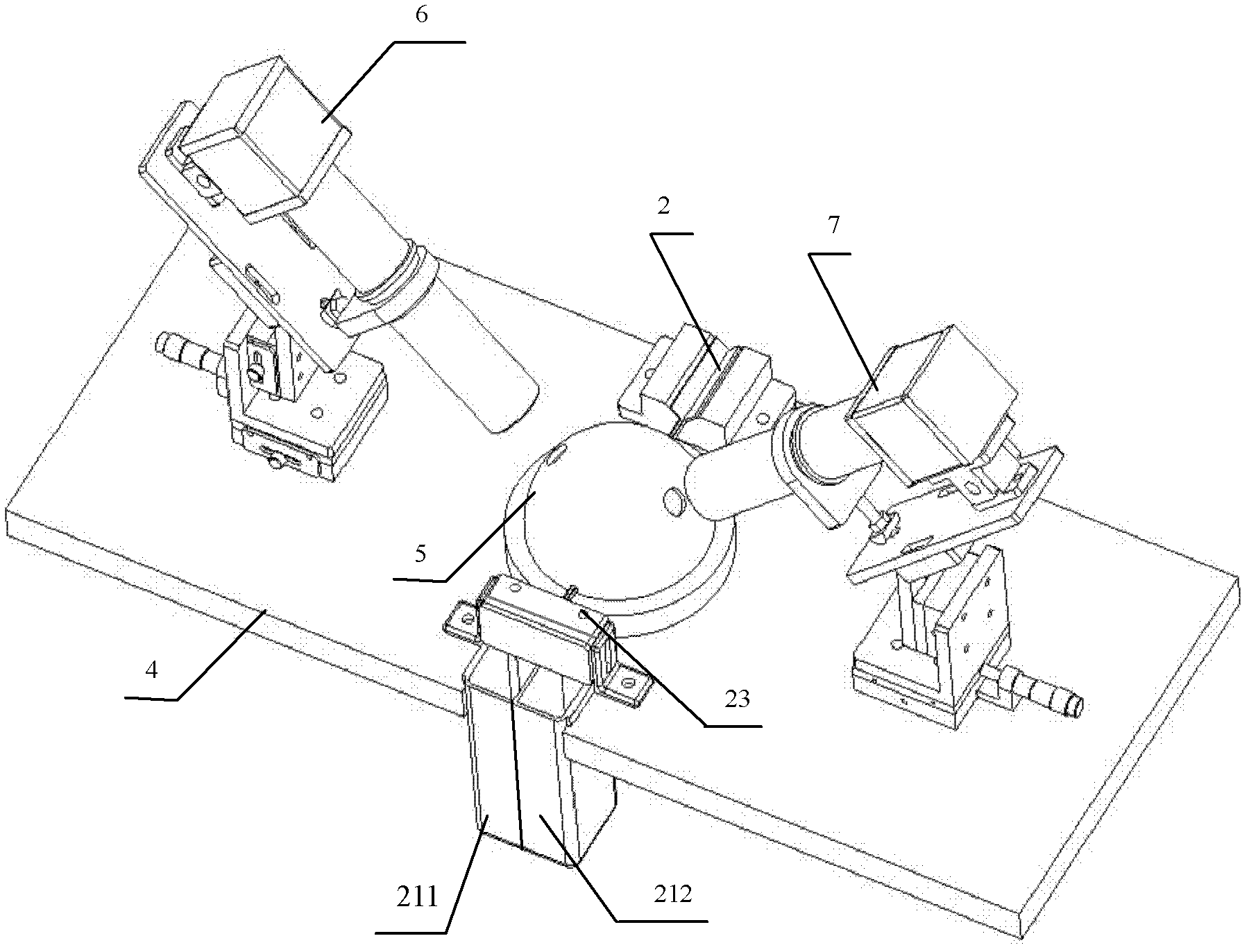

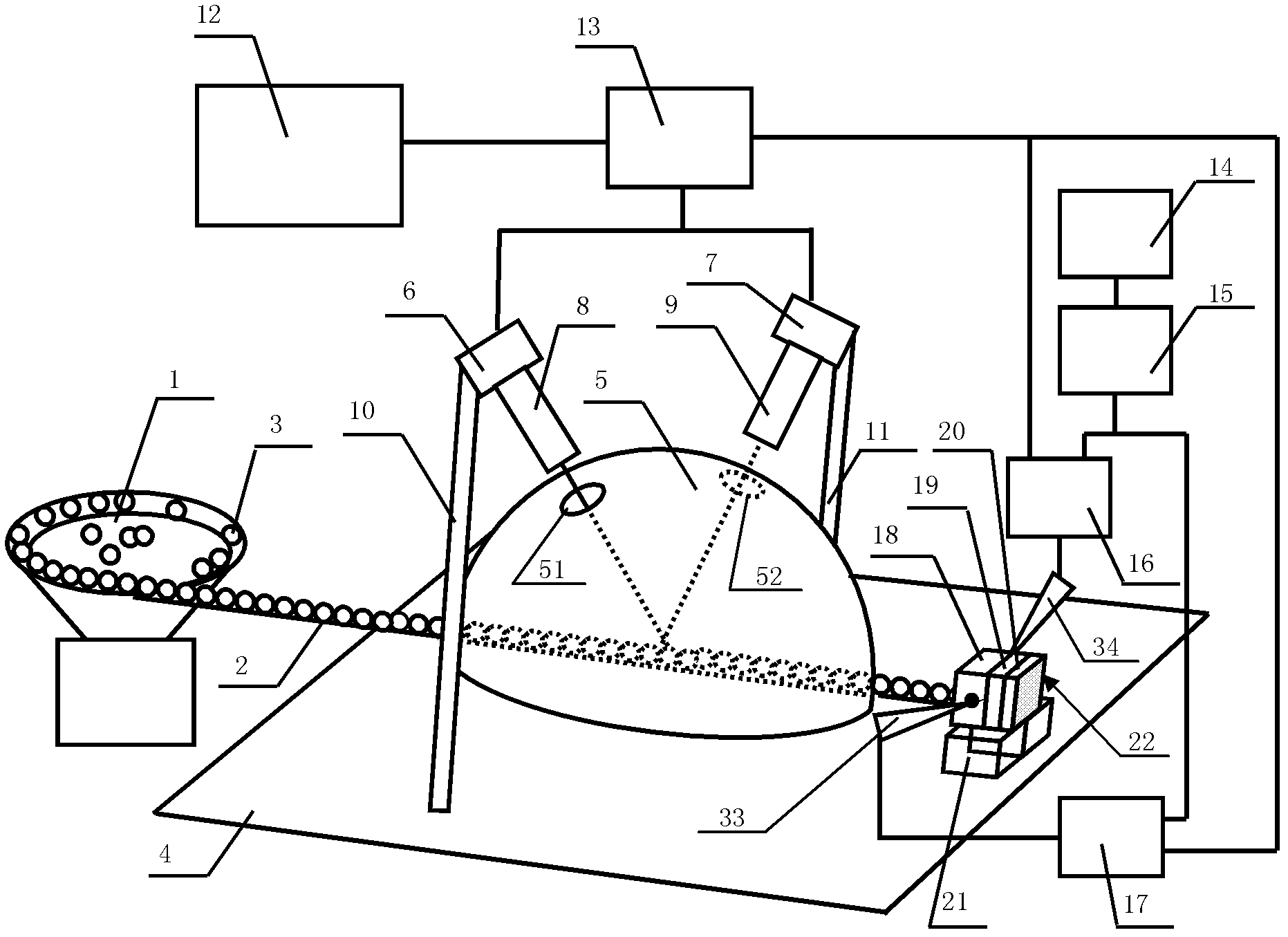

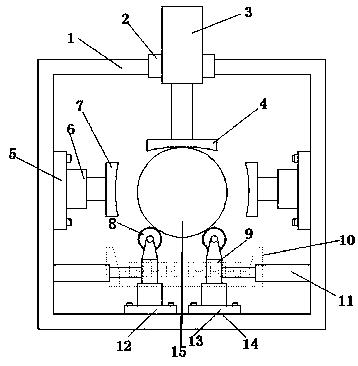

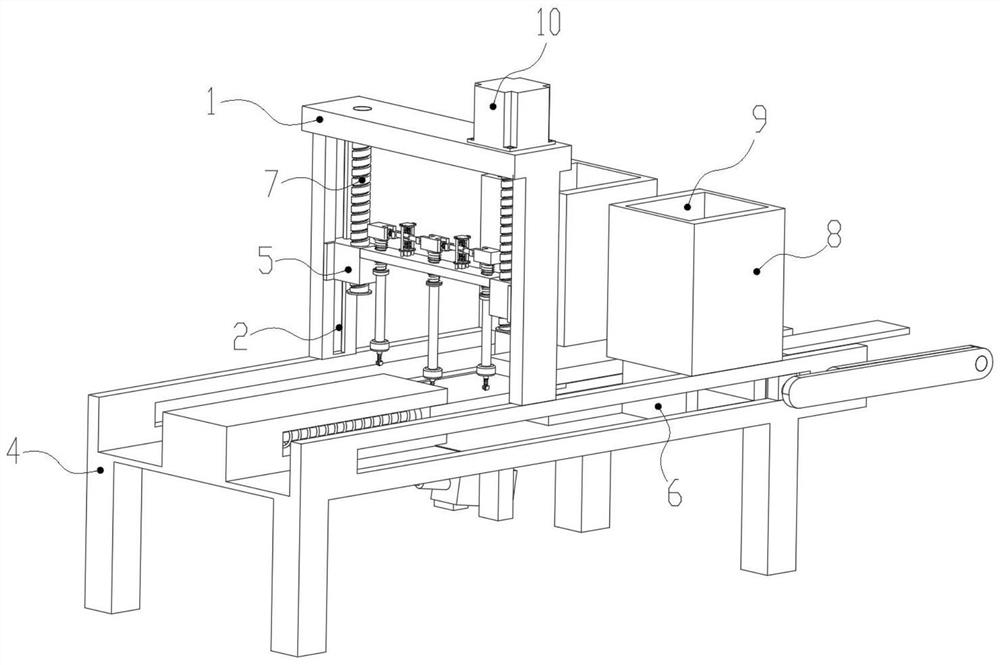

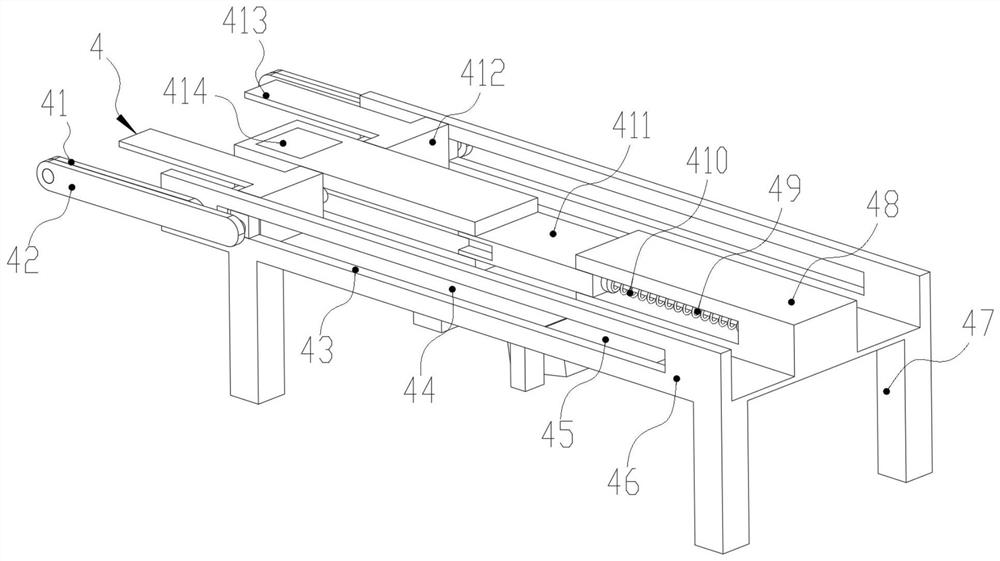

Steel ball surface defect detection automatic sorting device

InactiveCN102680490ARealize automatic feeding processEasy to detectOptically investigating flaws/contaminationSortingSteel ballInterconnection

Disclosed is a steel ball surface defect detection automatic sorting device. A light source is arranged on a work bench, a left camera mounted on a left support and a right camera mounted on a right support are symmetrically arranged on the left side and the right side of a light source bowl cover, camera lenses of the left camera and the right camera are arranged symmetrically and corresponding to a left observation hole and a right observation hole formed on the light source bowl cover, a vibration feed table and a material transferring channel connected to a discharge hole of the vibration feeding table are arranged behind the light source, the material transferring channel penetrates through the power source bowel cover and the front of the light source, a sorting mechanism and a collecting box placed below the sorting mechanism are arranged in front of the light source, a discharge terminal of the material transferring channel is inserted into a feeding hole end of the sorting mechanism, the left camera and the right camera are respectively connected with a peripheral component interconnection (PCI) card, PCI cards are respectively connected with a computer and a pneumatic unit, and an output end of the pneumatic unit is connected with the sorting mechanism. According to the steel ball surface defect detection automatic sorting device, the detecting process can achieve automation completely, no easily-worn part exists, the service life is long, and defect detection is accurate and efficient.

Owner:TIANJIN UNIV

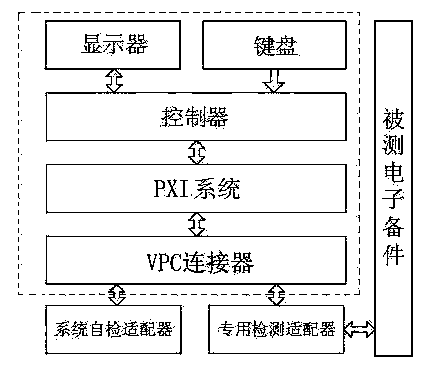

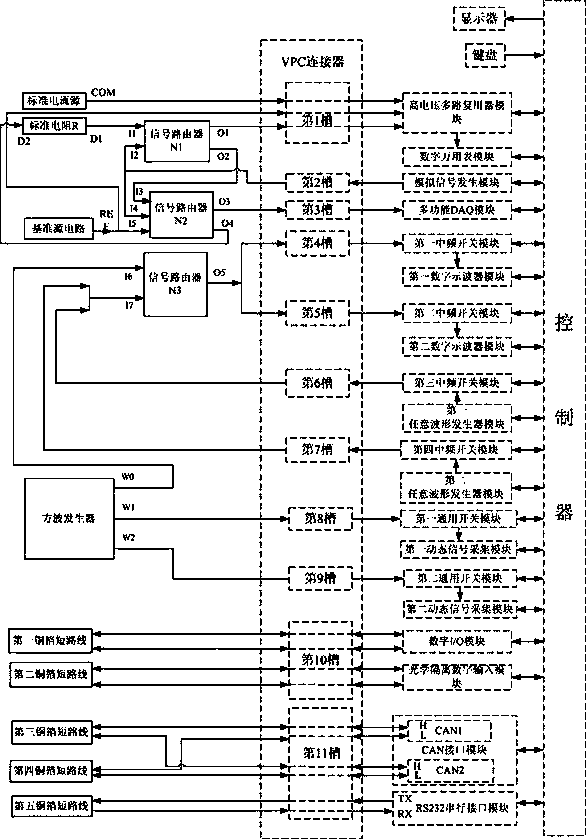

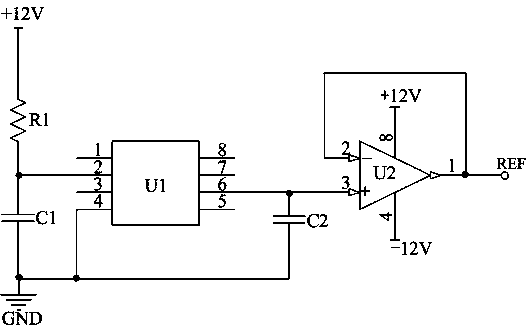

Electronic replacement part technology state automatic detection system and method based on PXI bus

InactiveCN103454522AEasy to separateConducive to design and developmentElectronic circuit testingElectrical measurement instrument detailsSquare waveformDisplay device

The invention discloses an electronic replacement part technology state automatic detection system based on a PXI bus. The replacement part technology state automatic detection system based on the PXI bus comprises a controller with automatic detection system software, a PXI system, a VPC connector, an adaptor, a keyboard connected with the controller and a displayer, wherein the PXI system is formed by a PXI case and more than two PXI modules inserted into corresponding inserting grooves of the PXI case; the adaptor comprises a system self-test adaptor; the controller is connected with the PXI case through the PXI bus; signal ends of all PXI modules are connected with the self-test adaptor or a special test adaptor through the VPC connector; the system self-test adaptor comprises a standard current source, a standard resistor R, a reference source circuit, a square-wave generator, a signal route N1, a signal route N2, a signal route N3, a first copper foil short-circuit wire, a second copper foil short-circuit wire, a third copper foil short-circuit wire, a fourth copper foil short-circuit wire and a fifth copper foil short-circuit wire. The replacement part technology state automatic detection system based on the PXI bus has the advantages that due to the adoption of the adaptor, separating performance of an electronic replacement part to be tested and a PXI port is good, the system has good universality and expansibility, polytypic signals can be tested, and detection automation degree is high.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

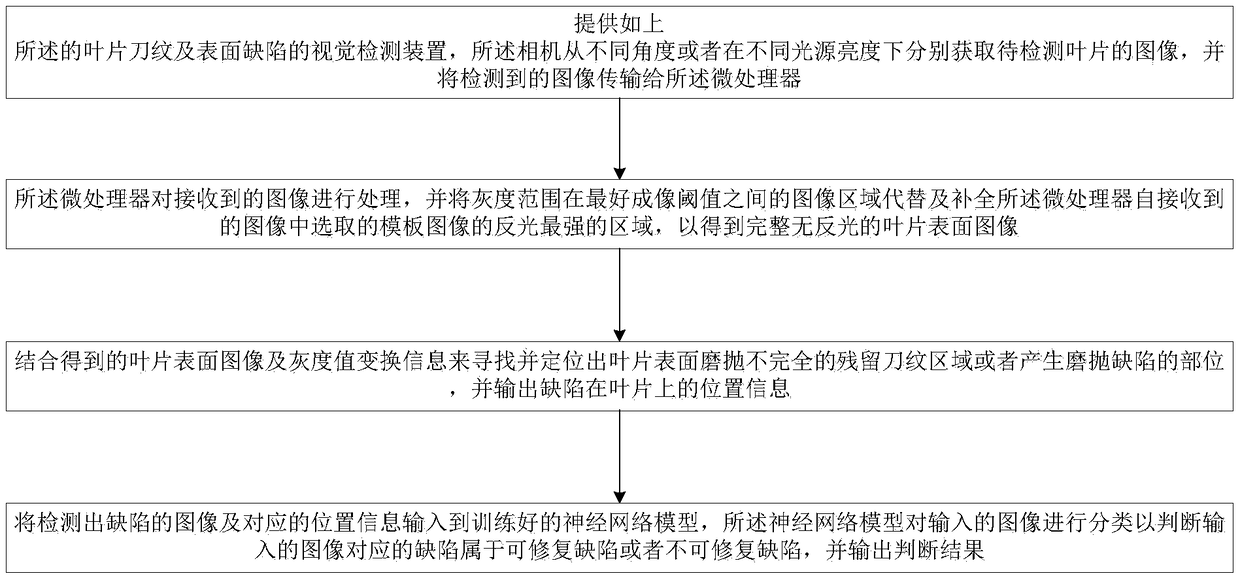

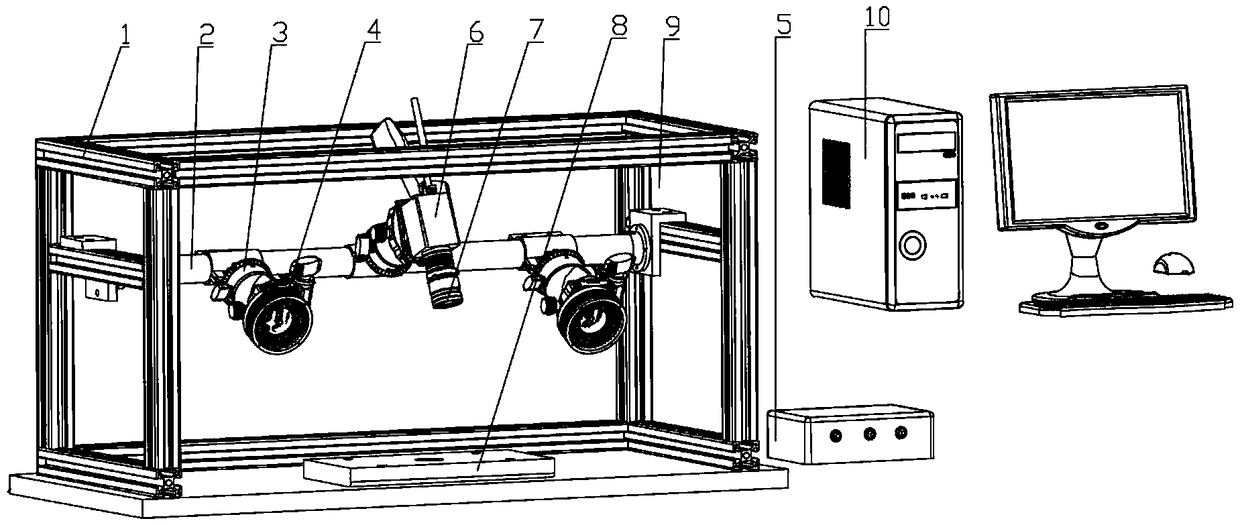

Visual detection device and method for blade pattern and surface defect

ActiveCN109030498AImprove detection accuracyImprove detection efficiencyOptically investigating flaws/contaminationGray levelLight reflection

The invention belongs to the technical field of intelligent detection, and discloses a visual detection device and method for a blade pattern and a surface defect. The method comprises the following steps that (1) the visual detection device is provided, and a camera respectively acquires images of a to-be-detected blade from different angles or under different light source brightness and transmits the detected images to a microprocessor; (2) the microprocessor processes the received images and replaces and complements an area with the strongest light reflection of a template image selected from the received images by the microprocessor with an image area with the gray level range between the optimal imaging thresholds; (3) a residual pattern area with incomplete grinding and polishing onthe surface of a blade or a part for generating a grinding and polishing defect is found and positioned; and (4) a neural network model classifies the images with the detected defects in order to judge whether the defects corresponding to the input images can be repaired or not. According to the device and the method, the detection efficiency and accuracy are improved, the automation degree is high, and the cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

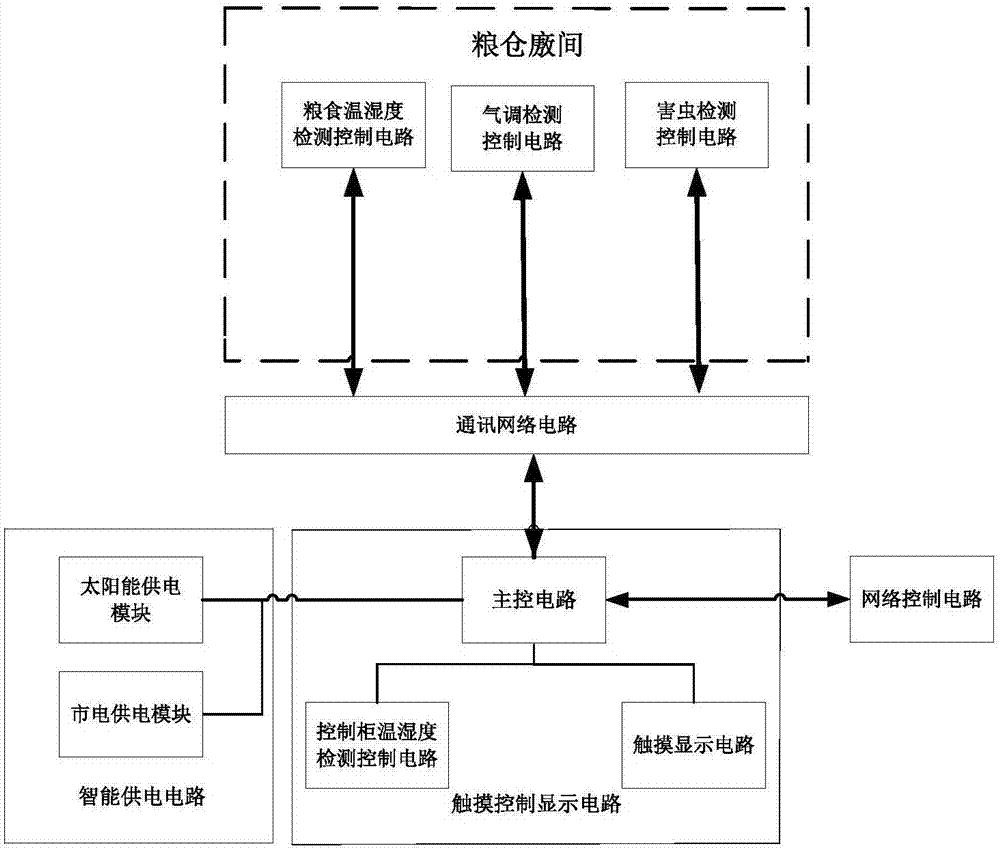

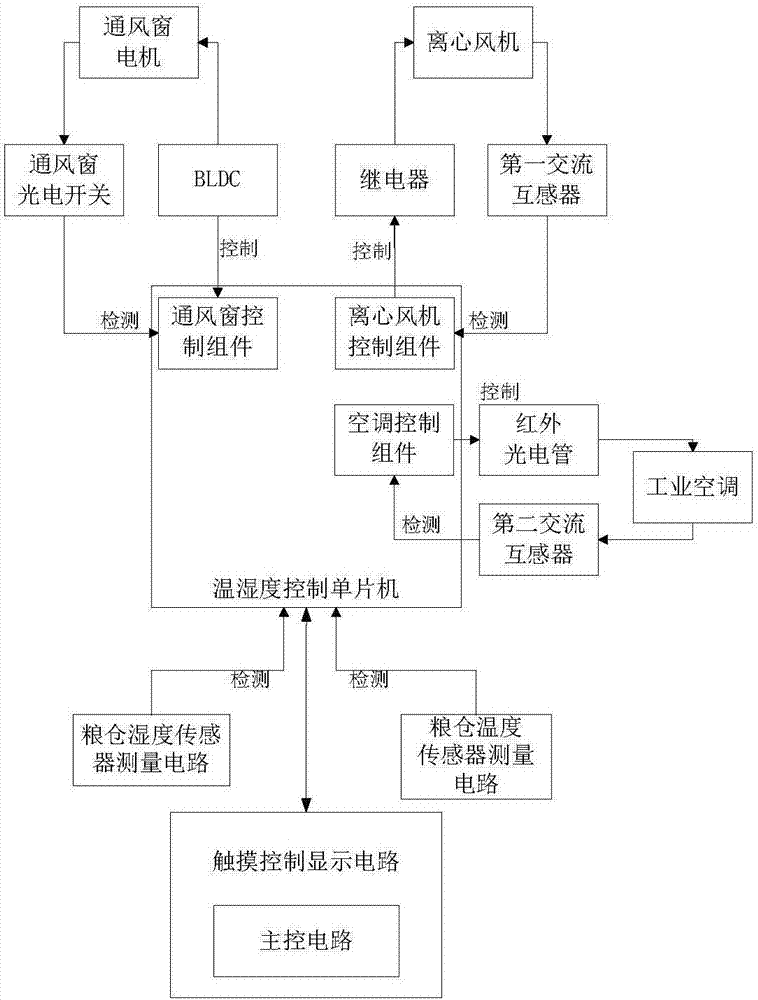

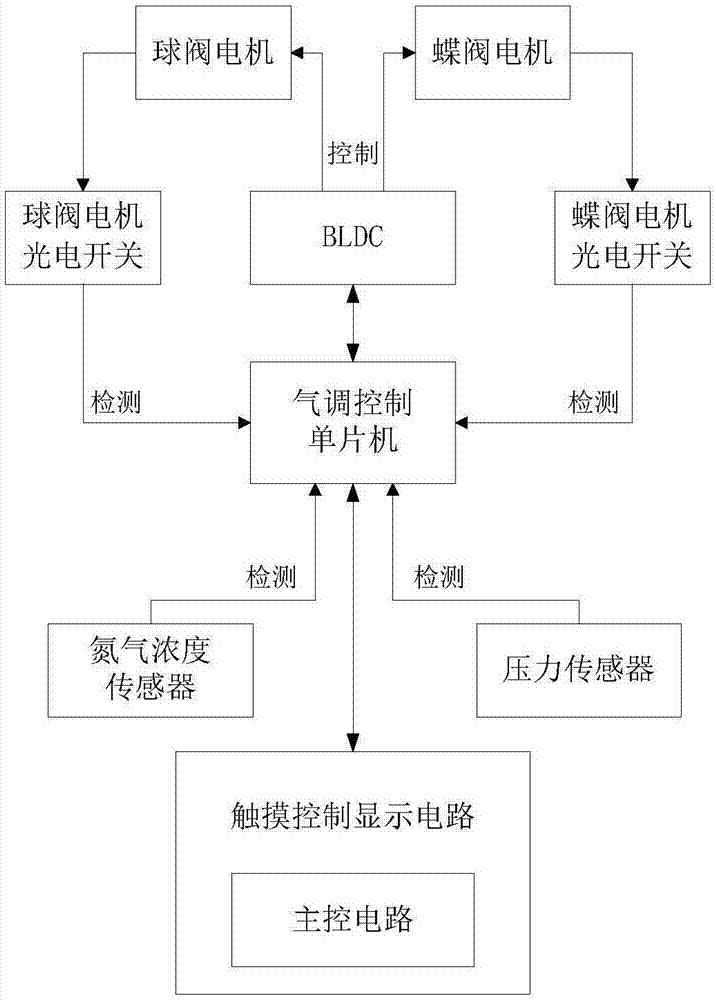

Control circuit of intelligent and integrated display control system of granary

ActiveCN107168273AImprove detection accuracyHigh degree of detection automationTotal factory controlSimultaneous control of multiple variablesAnalog circuit designControl system

The invention discloses a control circuit of an intelligent and integrated display control system of a granary. The control circuit comprises a grain temperature and humidity detection control circuit, a gas conditioning detection control circuit, a pest detection control circuit, an intelligent power supply circuit, a communication network circuit, a touch control display circuit and a network control circuit, wherein the intelligent power supply circuit is connected with the touch control display circuit, the touch control display circuit is connected with the grain temperature and humidity detection control circuit, the gas conditioning detection control circuit and the pest detection control circuit by means of the communication network circuit, and the touch control display circuit comprises a main control circuit, a touch display circuit connected with the main control circuit and a control cabinet temperature and humidity detection control circuit, thus the corresponding control system can be adjusted in one or more ways of a local intelligent mode, a local manual mode, a network intelligent mode and a network manual mode. The control circuit adopts a modular and analog circuit design, and creates an ideal grain storage environment.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

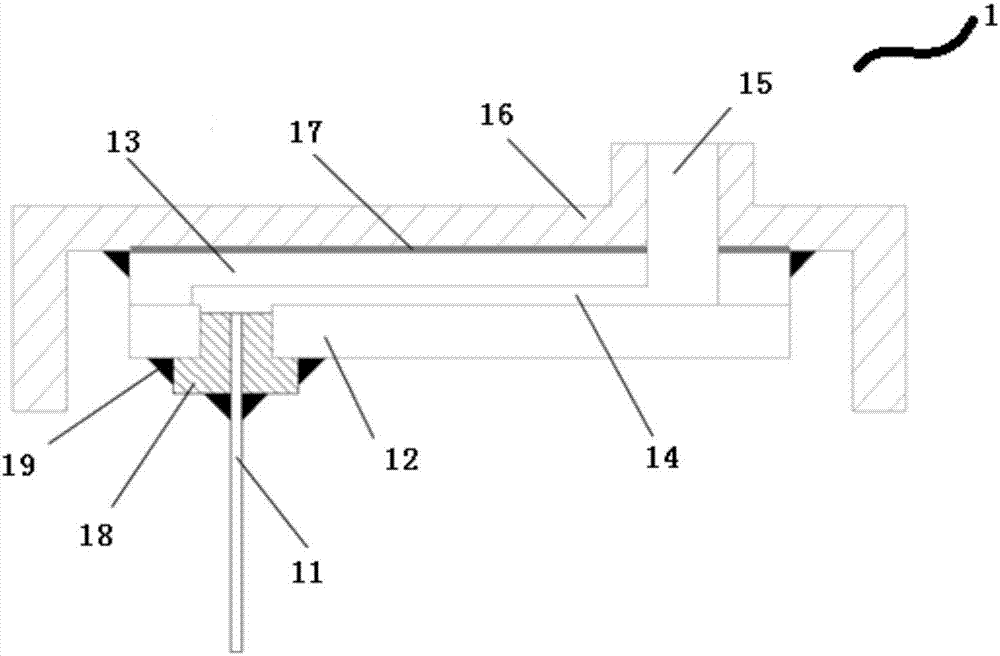

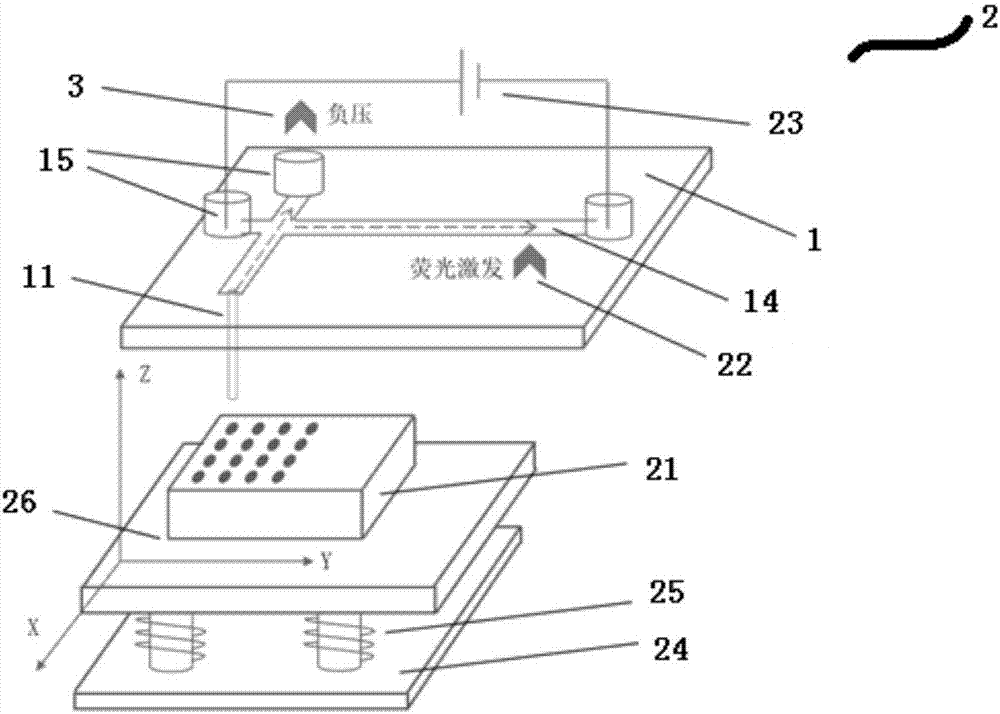

Automatic sample injection system based on micro-fluidic chip

ActiveCN106984370AIncrease the level of automationImproved sampling methodLaboratory glasswaresInjection portPressure controlled ventilation

The invention discloses an automatic sample injection system based on a micro-fluidic chip. The automatic sample injection system comprises a micro-fluidic chip and a sample injection device for inputting samples into the micro-fluidic chip, and further comprises a negative pressure control device for generating negative pressure, wherein the sample injection device comprises a porous plate for accommodating samples; a suction needle is connected to the sample injection port of the micro-fluidic chip in a sealed manner; the negative pressure control device generates air pressure from the porous plate to the micro-fluidic chip, so that the samples in the porous plate are sucked into the micro-fluidic chip through the suction needle. According to the automatic sample injection system, the samples are directly led into the micro-fluidic chip through the suction needle by virtue of the negative pressure, manual sample adding is avoided, the detection automation degree is improved, and the cross contamination risk is reduced.

Owner:北京旌准医疗科技有限公司

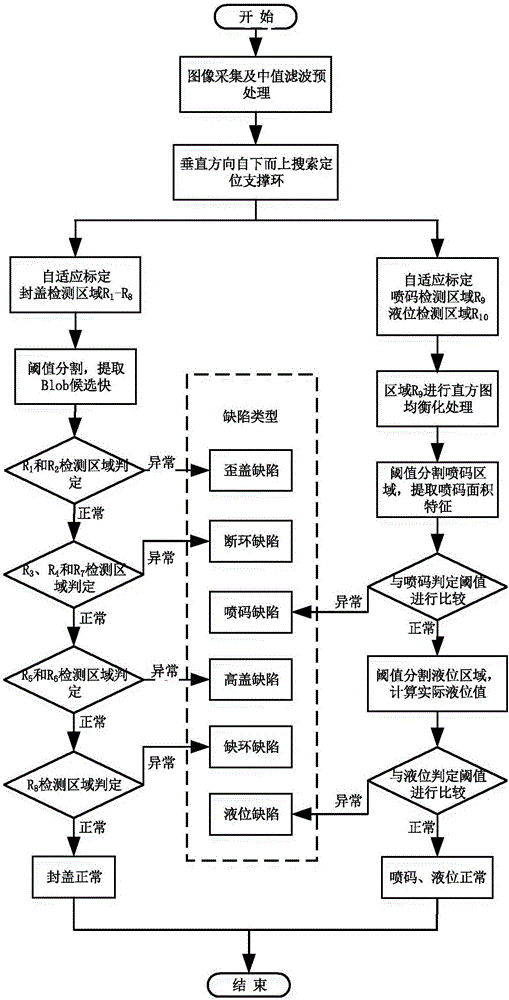

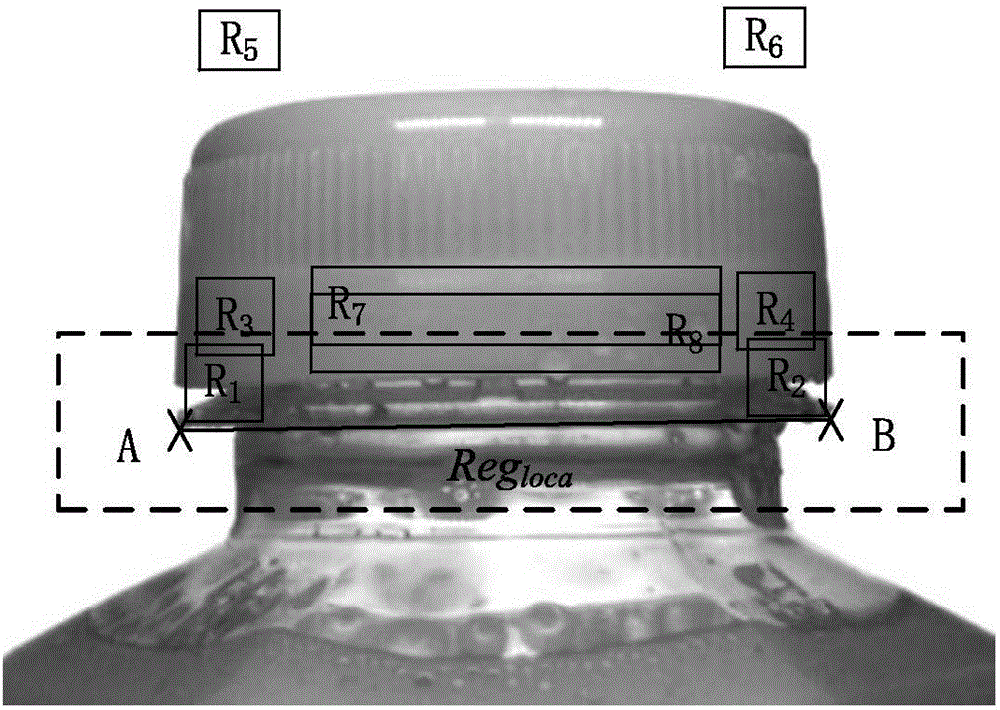

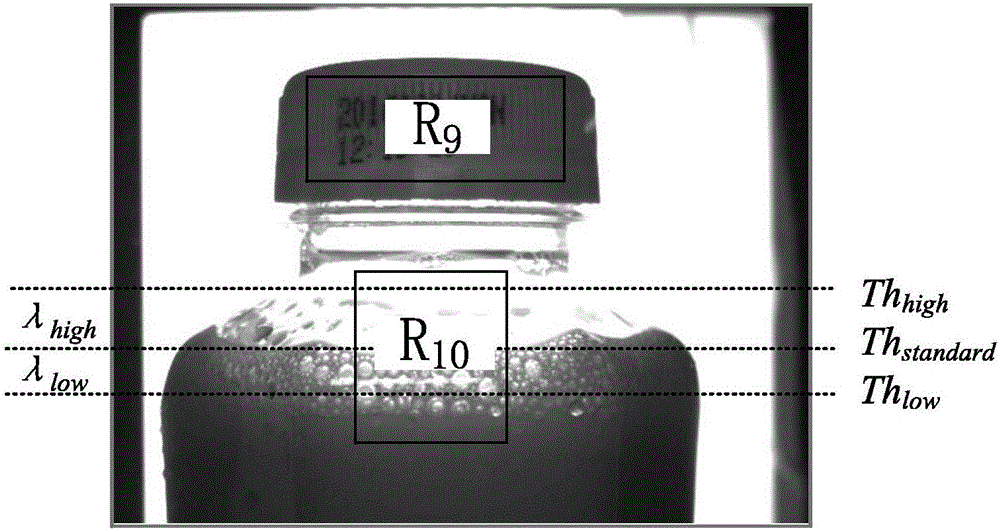

Visual inspection method for bottle packaging quality

ActiveCN106370659AHigh degree of detection automationEliminate positioning effectsImage analysisOptically investigating flaws/contaminationSelf adaptiveAutonomation

The invention discloses a visual inspection method for bottle packaging quality. The visual inspection method comprises the following steps: (1) acquiring a bottle image and carrying out preprocessing; (2) locating a support ring by using the strategy of longitudinal bottom-to-top searching; (3) carrying out self-adaptive calibration of a capping cover, a liquid level and a sprayed-code detection area; and (4) extracting a Blob candidate block by using a gray threshold segmentation algorithm and determining whether the capping cover, the liquid level and the sprayed-code detection area have defects according to determination rules. The visual inspection method overcomes the problems of slow speed, low efficiency and poor precision of artificial inspection; moreover, the method overcomes the problems that conventional visual inspection algorithms are complex, consume a long period of time in inspection and cannot meet demands on inspection of PET bottles on a high-speed production line, and improves the automation degree of bottle inspection.

Owner:XIANGTAN UNIV

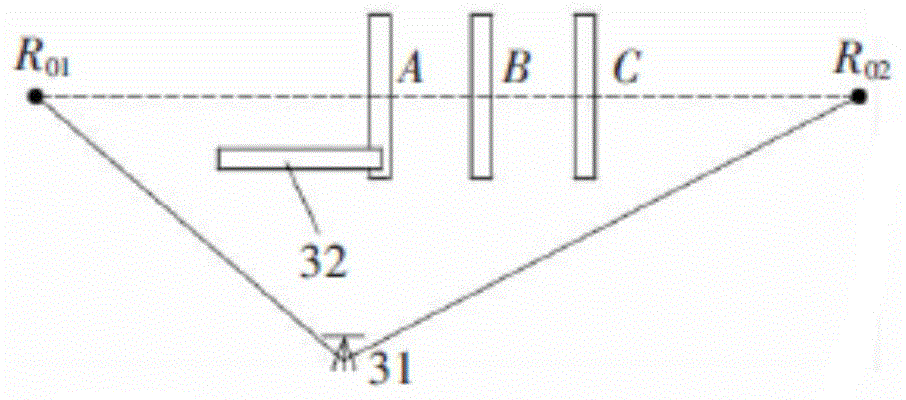

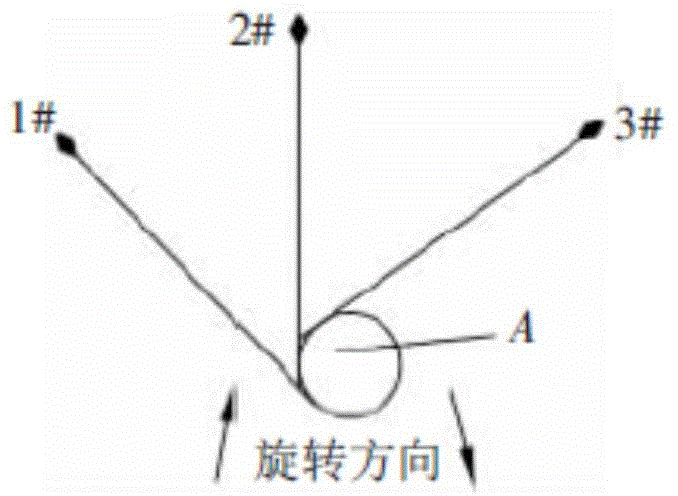

Method for deviation adjustment for detection of spatial position of steel belt roll system

InactiveCN103983187AImprove detection accuracyHigh degree of detection automationUsing optical meansTotal stationData point

The invention relates to a method for deviation adjustment for detection of the spatial position of a steel belt roll system. A datum point R01 and a datum point R02 located on the portions, on the two sides of the roll system, of a device bearing the steel belt roll system and on the center axis of the roll system are selected; a total station is erected between the two datum points; the position of the total station is set to serve as an origin of space coordinates, the connecting line of the two datum points serves as the X direction, the Z direction is vertically upwards, and the coordinates of the datum point R01 and the datum point R02 are detected through the total station; a detected roll shaft is rotated, the space coordinates of at least three different rotation positions on one vertical section of the detected roll shaft are detected through the total station; the coordinates of the center of a circle where each point is located are obtained by a computer system, and therefore the space coordinates of each point on the central axis of a steel roll are obtained; the space coordinates of the points on the central axis of the detected steel roll are compared with the space coordinates of the points on the central axis at the steel roll standard position obtained in advance and the deviation directions and the deviation distances of the points on the central axis are obtained; according to the deviation directions and the deviation distances, space position adjustment is conducted on the detected steel roll.

Owner:上海宝冶工程技术有限公司

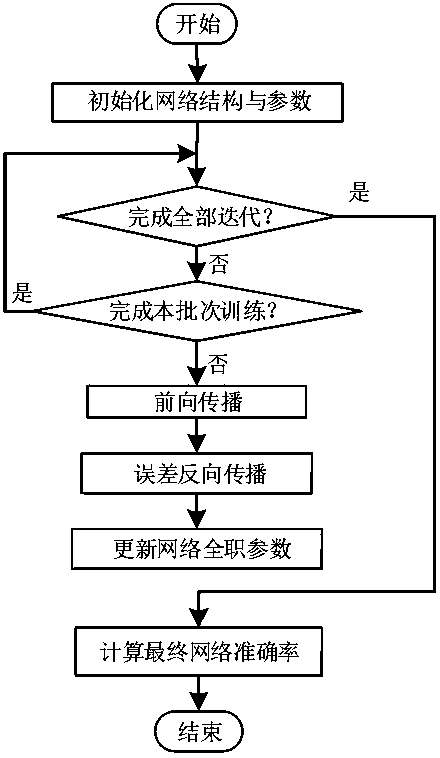

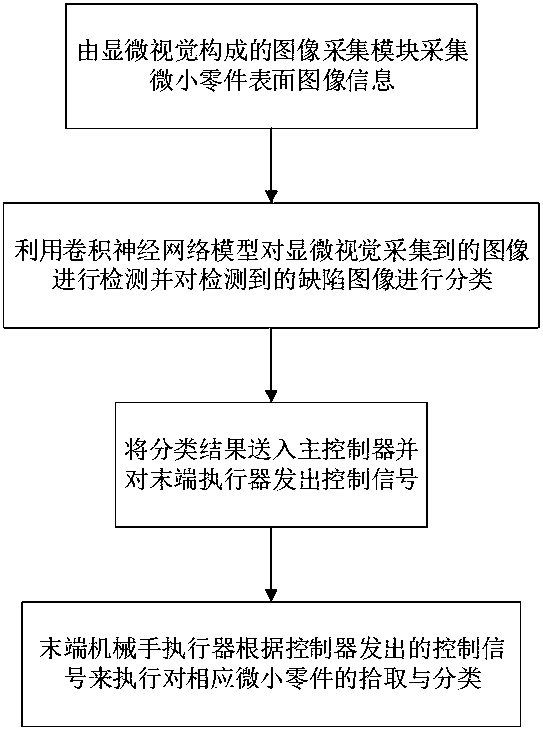

Micro part quality detection system based on convolutional neural network

InactiveCN108672316AHigh degree of detection automationImprove detection accuracyOptically investigating flaws/contaminationSortingRobot handControl signal

The invention discloses a micro part quality detection system based on a convolutional neural network. The micro part quality detection system comprises: A, collecting the surface image information ofa micro part by an image acquisition module formed by microscopic vision; B, detecting the image collected by the microscopic vision by using a convolutional neural network model, and classifying thedetected defect images; C, transmitting the classifying result into a main controller, and sending a control signal to a terminal actuator; and D, carrying out picking and classifying on the corresponding micro part by the terminal mechanical arm actuator according to the control signal transmitted by the controller so as to convey the part into the corresponding receiving box, such that the whole system completes the detection and defect classification on the surface quality of the micro part. According to the present invention, the system can effectively used for the detection of micro parts, and can improve the automation degree and the efficiency of detection, and reduce the influence of human factors on the detection process and the labor intensity of workers.

Owner:HARBIN UNIV OF SCI & TECH

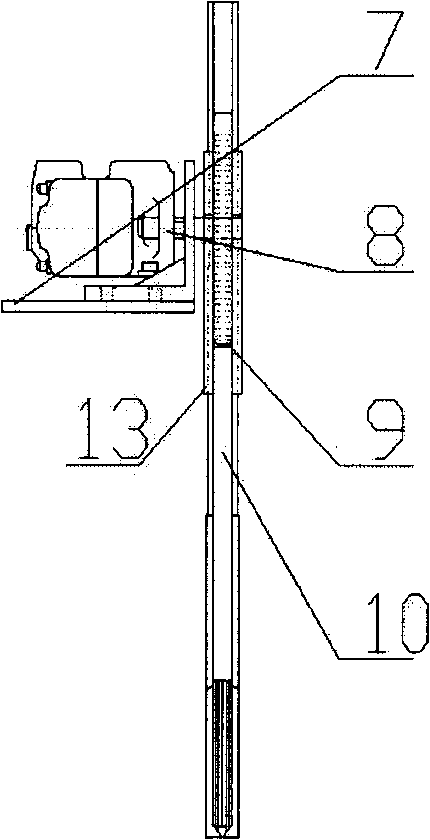

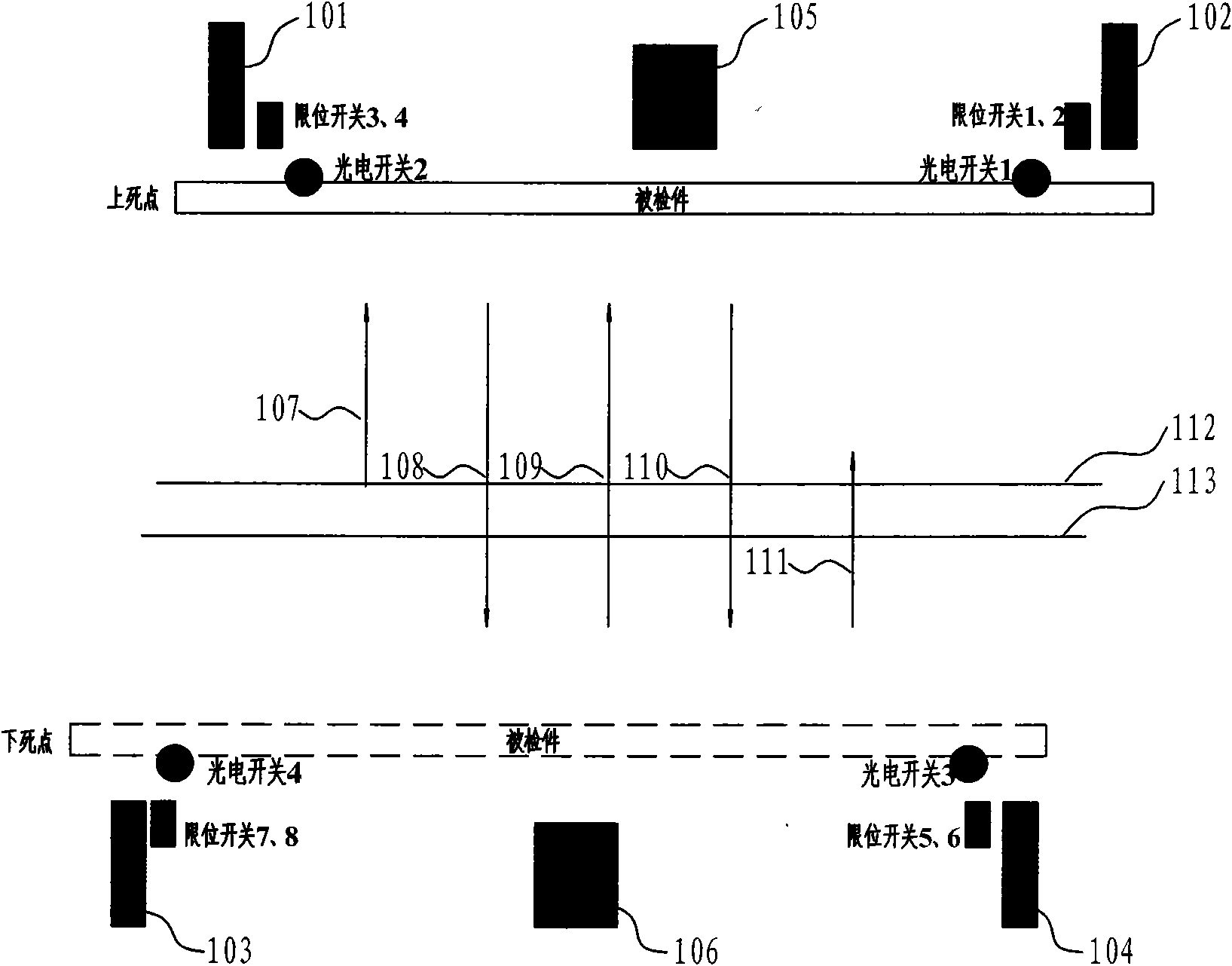

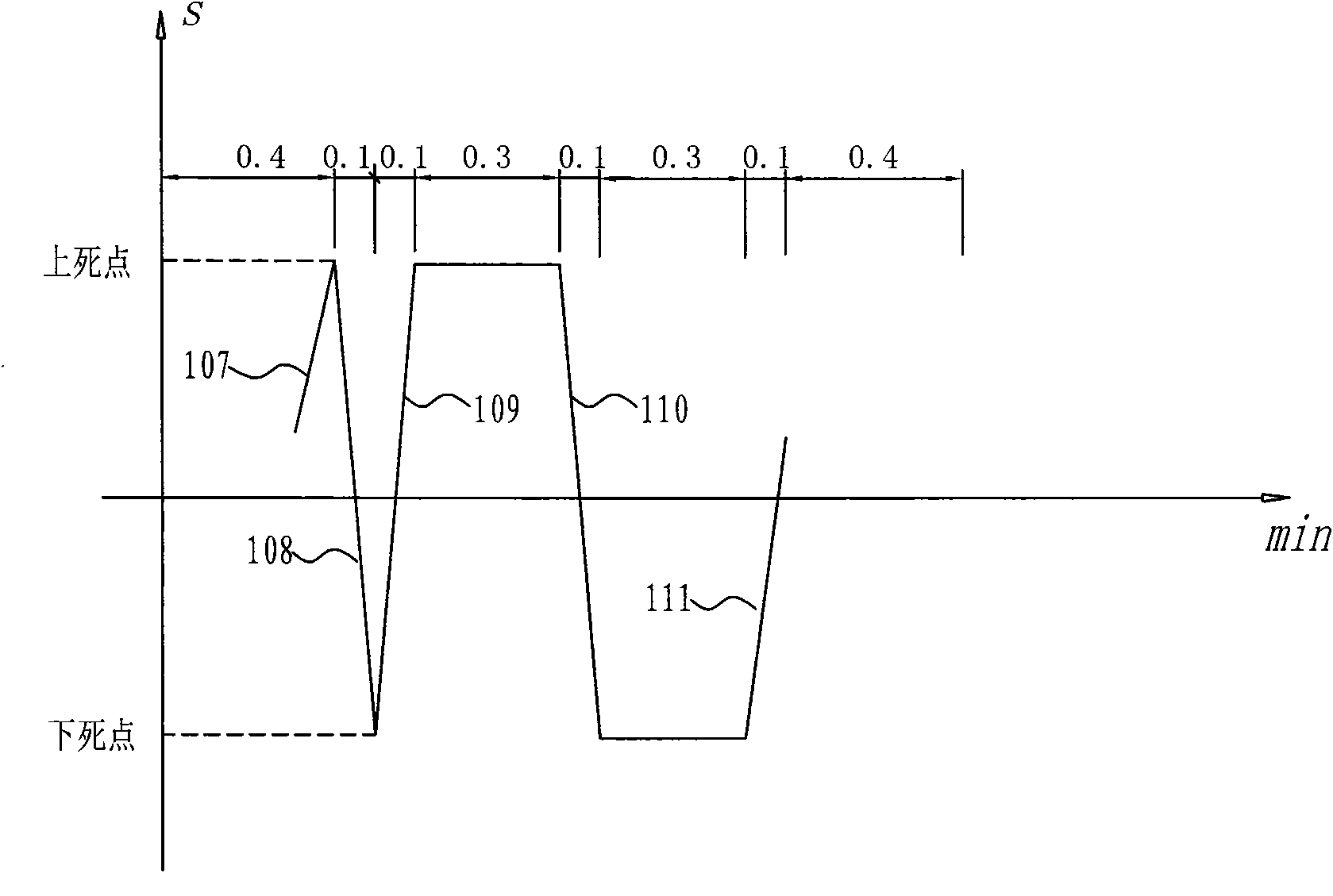

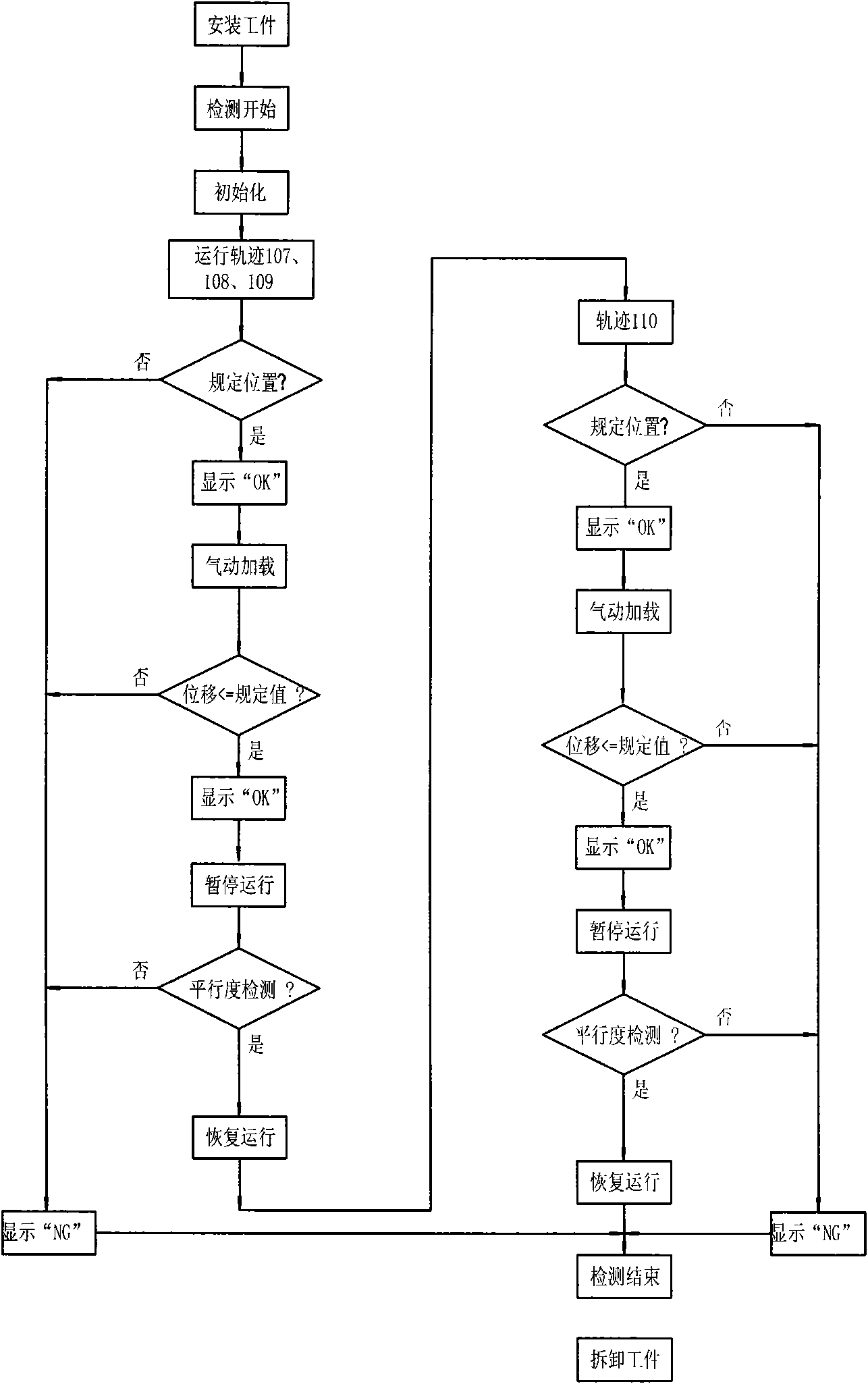

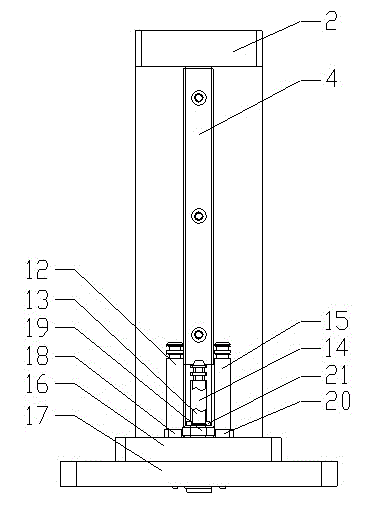

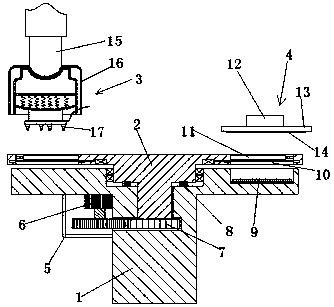

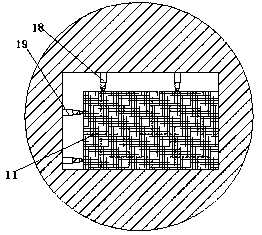

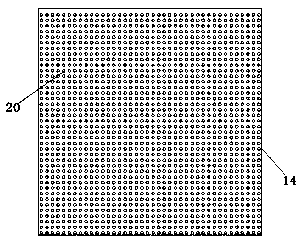

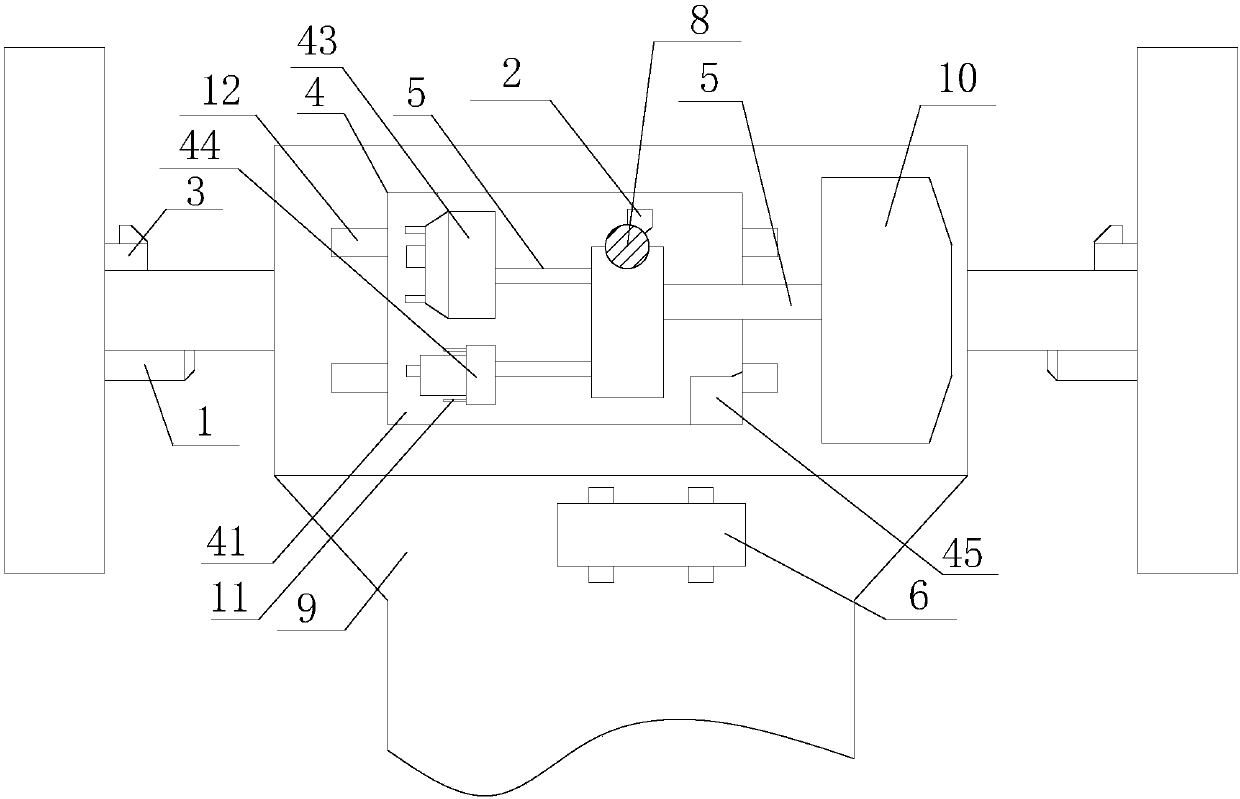

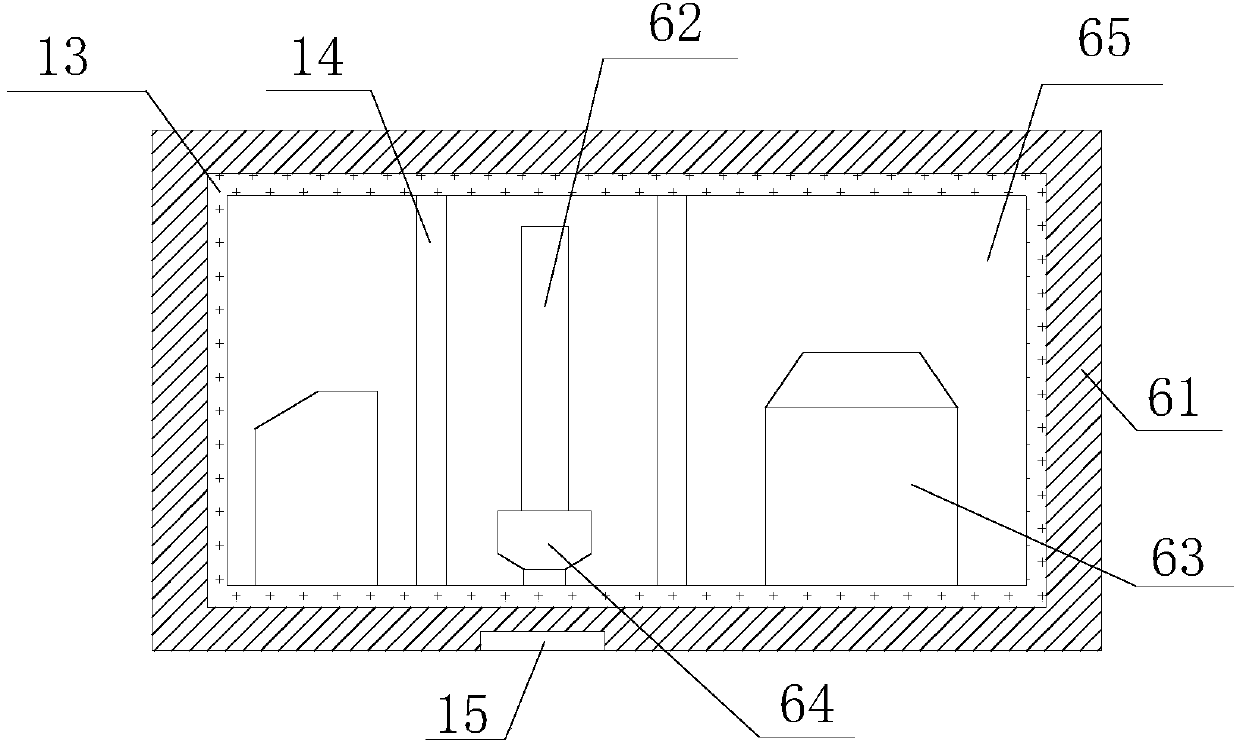

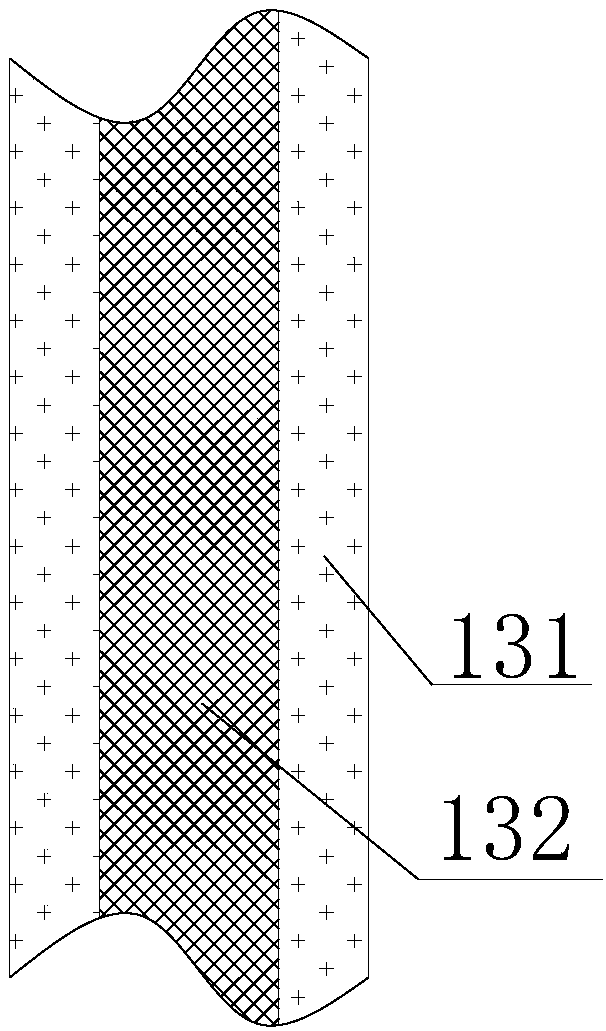

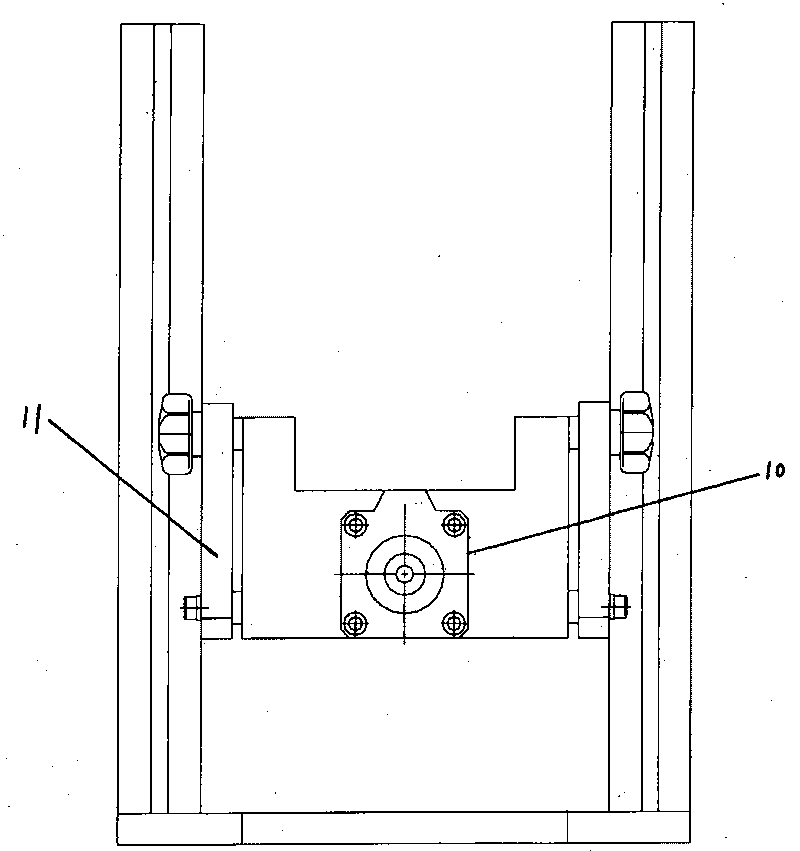

Intelligent testing method of lifter and testing device

InactiveCN101539492AHigh degree of detection automationEasy to operateStructural/machines measurementPerformance indexEngineering

The invention discloses an intelligent testing method of a lifter and a testing device. The testing device comprises a mechanical body, a clamping component used for clamping the lifter, a testing component used for testing the lifter, a pneumatic component and a control mechanism. The intelligent testing method and the testing device integrate mechanical, electric and pneumatic functions into one machine and are used for testing all the performance indexes of the lifter, so that the technical problems of inconvenient operation and lower accuracy of the existing testing device of the lifter; meanwhile, the invention also has the advantages of compact structure, small volume, beautiful appearance, high linearity, accurate detection, long service life, easy maintenance, etc.

Owner:李颖卓

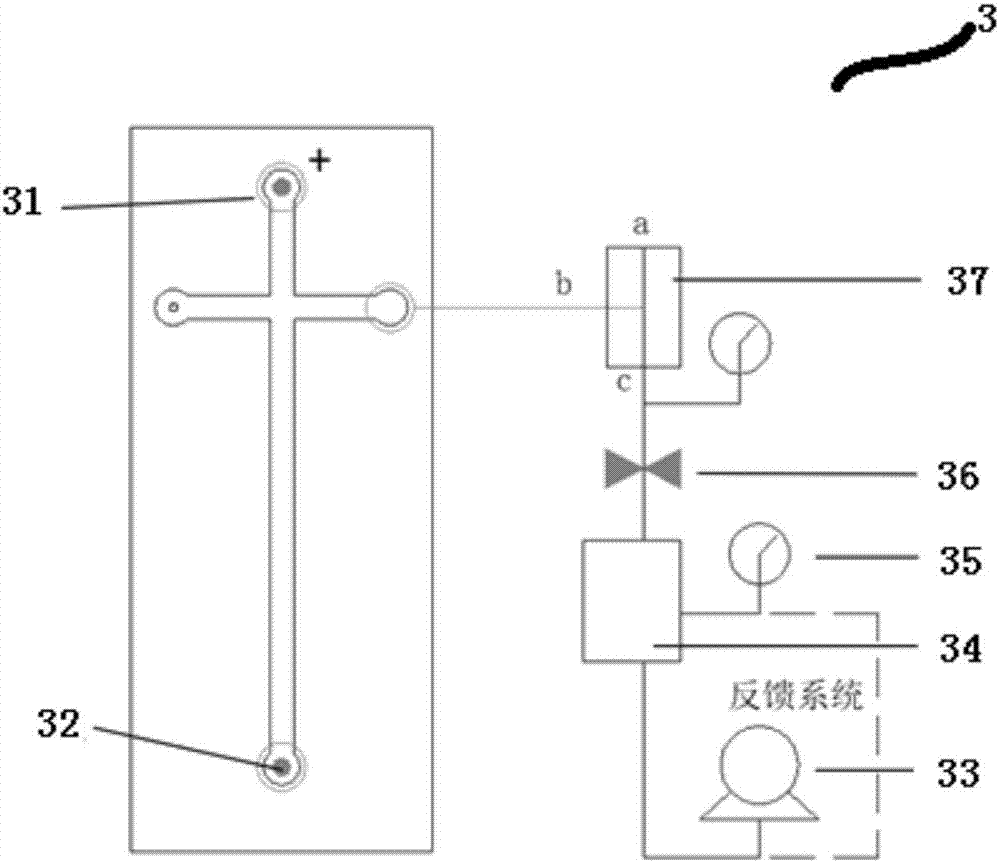

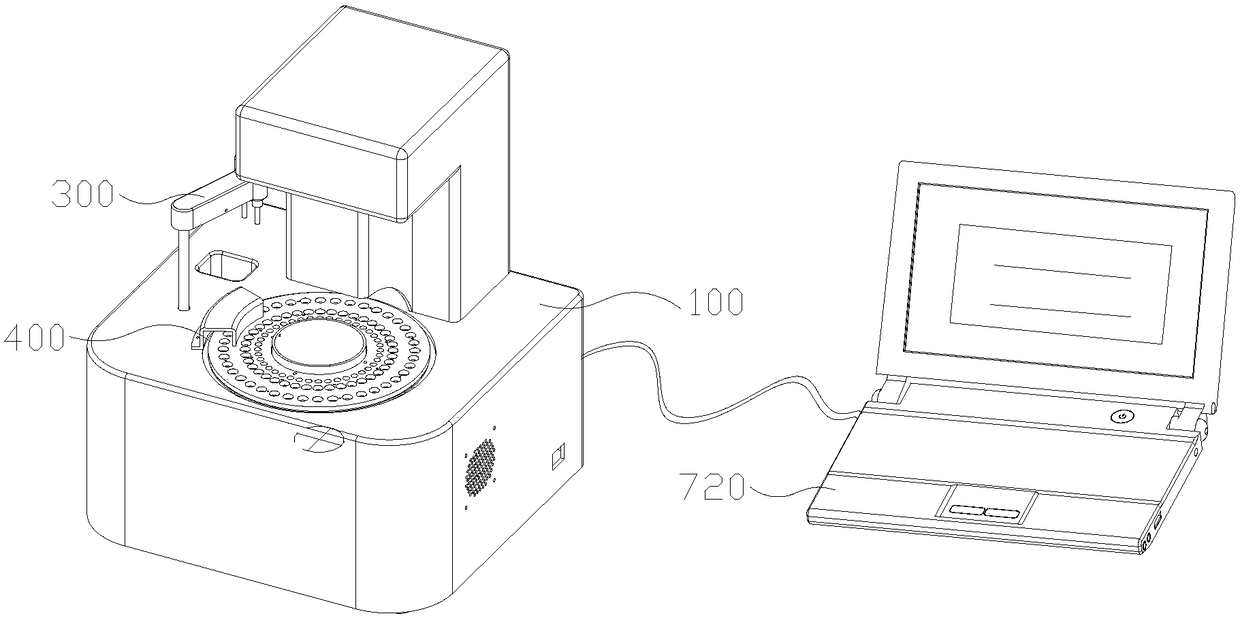

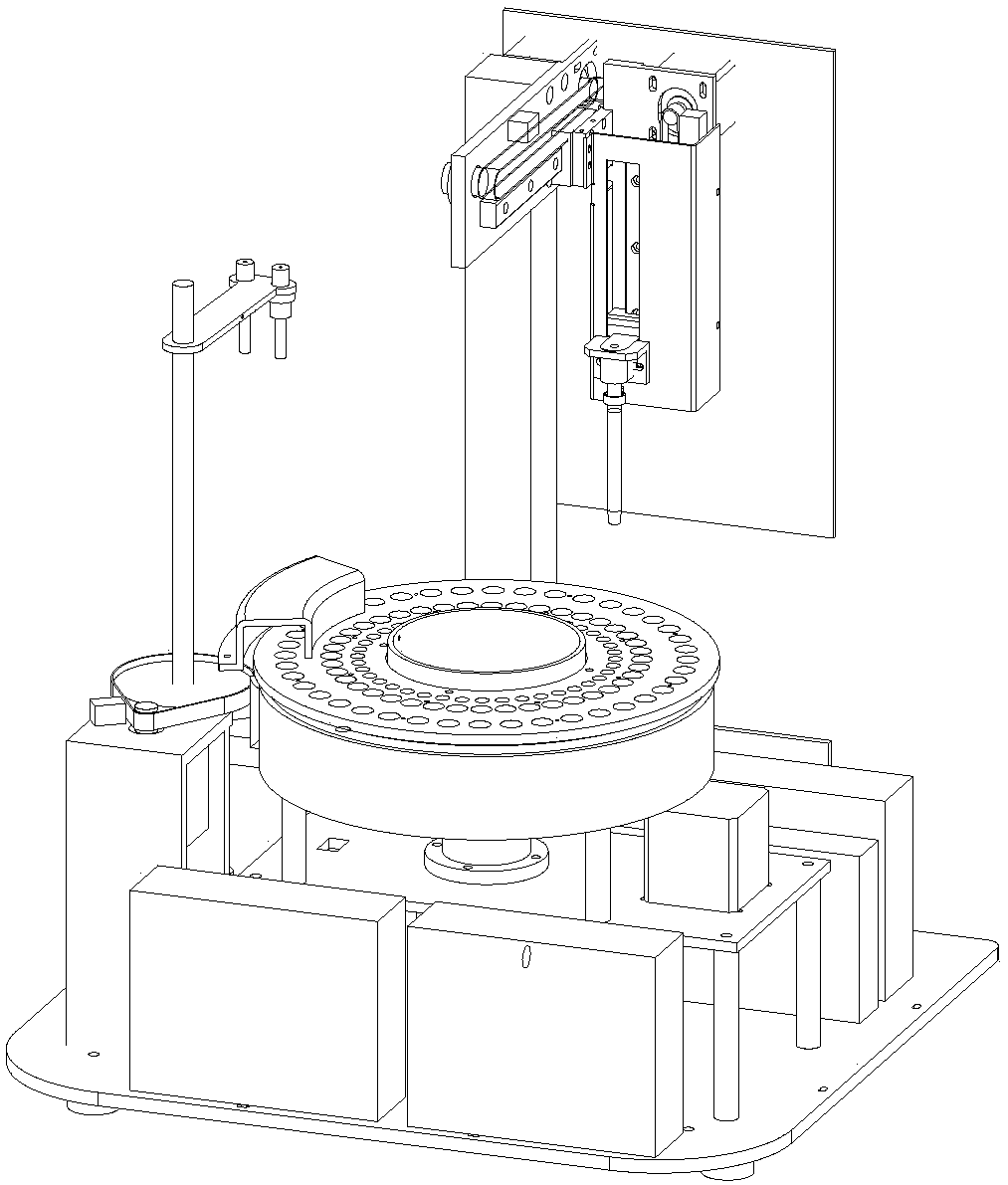

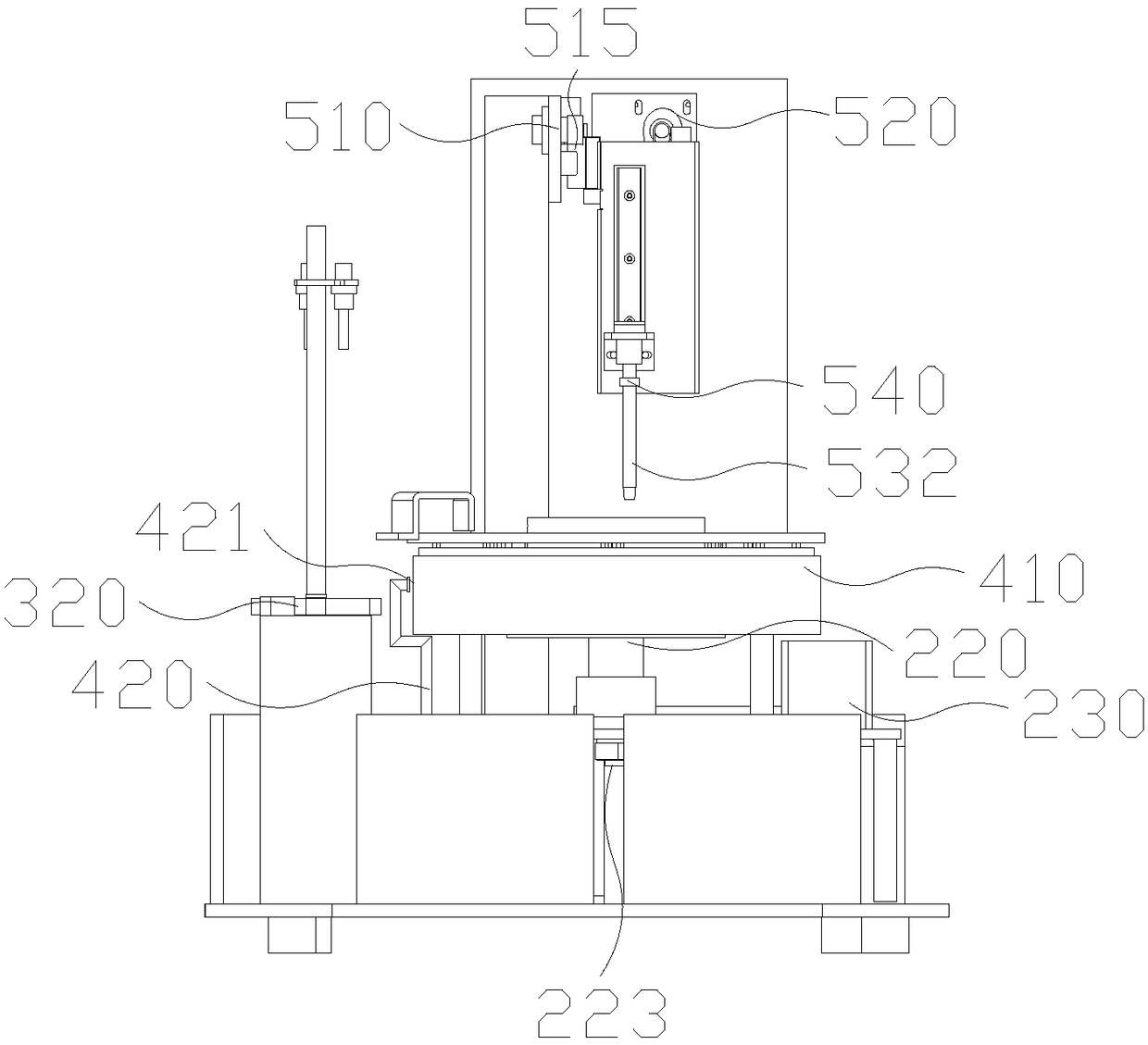

Full-automatic intelligent urine iodine analyzer and operating method thereof

PendingCN108152285AHigh degree of detection automationImprove detection accuracyMaterial analysis by observing effect on chemical indicatorEngineeringElectric control

The invention relates to a full-automatic intelligent urine iodine analyzer, which comprises a shell, a sample carrier mechanism, a reagent liquid adding device, a light path detection system, a comprehensive sample processing mechanism, a waste trough and an electric control system. By adoption of a quantitative colorimetric method, point-to-point operation of various reagents is realized throughcontrol of reagent disc rotation; by adoption of a sample adding stirring device, mixing of to-be-tested reagents is realized, cross contamination of samples is avoided, and mixing efficiency is improved; by a double-reagent-needle sample adding arm, a color developing agent and an oxidant adding function is realized, detection time is shortened, and internal and external spaces of equipment aresaved; functions of automatic result interpretation and automatic report printing are achieved, urine iodine detection automation is improved, errors caused by manual sample adding are effectively avoided, urinalysis detection precision and detection efficiency are improved, and detection cost is reduced.

Owner:王鲁生

Machine vision based on-line detection system and detection method thereof

PendingCN105466946AImprove detection efficiencyHigh degree of detection automationOptically investigating flaws/contaminationProduction lineMachine vision

Being applicable to the technical field of display unit detection, the invention discloses a machine vision based on-line detection system and a detection method thereof. The machine vision based on-line detection system consists of a darkroom equipped machine body, which strides over a conveyer line, the conveyer line is used for conveying a display unit and loading the protection tooling of the display unit. The darkroom is internally provided with an imaging device, and is equipped with an overturning component for tunring over the display unit or the display unit and the protection tooling to make the display unit face the imaging device, the display unit is in connection with a terminal box, and the darkroom is internally provided with a butt joint butted with the terminal box. The machine vision based on-line detection method adopts the machine vision based on-line detection system. The machine vision based on-line detection system and the detection method provided by the invention can realize continuous production and detection, have no need to take the display unit from the production line, and have the advantages of high detection efficiency, good detection effect, and high detection automation degree.

Owner:深圳市研祥智慧科技股份有限公司

Device for testing air tightness of four-way valve

InactiveCN102749175AHigh degree of detection automationFully automatedFluid-tightness measurement using fluid/vacuumTest efficiencyFour-way valve

The invention discloses a device for testing the air tightness of a four-way valve. A cylinder body of a cylinder is fixedly connected with a rack; a piston rod is fixedly connected with an elevating mechanism; the elevating mechanism is in sliding fit with a guide track of the rack so as to make linear reciprocated movement; a space for accommodating the four-way valve is arranged between a pressing plane and a rising plane of the elevating mechanism; the elevating mechanism is used for respectively applying action forces with opposite directions to the wall of a main tube along the radial direction of the main tube of the four-way valve through the pressing plane and the rising plane; four plugging columns are fixed on the rack; and the head parts of the four plugging columns are respectively provided with sealing heads for sealing nozzles of branch tubes of the four-way valve correspondingly; and a limiting rod is fixed on the rack and can be used for preventing the piston rod from moving continuously along the original direction while the sealing heads of the four plugging columns accomplish the sealing to the nozzles of the branch tubes of the four-way valve. With the adoption of the device, the labor cost can be reduced, and the measuring efficiency can be increased.

Owner:CHINA JILIANG UNIV

Electronic component testing device

ActiveCN108692662ARealize automated detectionRealize fully automated detectionElectrical testingUsing optical meansElectricityLight beam

The invention discloses an electronic component testing device, and the device can detect the size of an electronic component, and also can quickly detect the electrical performances of the electroniccomponent. The device is high in detection automation degree, and is reliable in detection. The device employs a multi-position mode for detection, and effectively reduces the labor intensity of detection. A multi-position rotating disc assembly can be cooperatively provided with feeding and discharging mechanical arms, thereby achieving the full-automatic detection. During detection, a jacking assembly jacks the electronic component to be fixed on a reference plane of a positioning groove at first when the feeding mechanical arm carries out the feeding operation, and then a vacuum absorptionassembly absorbs and fixes the electronic component. When the electronic component rotates to a size detection position, the device carries out the electronic component through a light beam, and a light beam receiver can judge the contour of the electronic component according to the received light, wherein the size can be calculated so as to judge whether the electronic component is qualified ornot: an electrical performance detection assembly is used for testing the electrical performances of the electronic component if the electronic component is qualified, or else, the mechanical arm takes out the unqualified product.

Owner:YULIN UNIV

Automatic detection device for round workpieces

ActiveCN108680118AImprove detection efficiencyPrecise positioningUsing optical meansEngineeringAutomation

The invention discloses an automatic detection device for round workpieces, can greatly improve workpiece detection efficiency, can excellently detect circumferential contours of the workpieces and realizes rapid detection on whether the workpieces are qualified. A light receiving detection assembly is capable of detecting the circumferential contours of the cylindrical workpieces, a controller iscapable of determining whether the cylindrical workpieces are qualified according to whether the circumferential contours detected by the light receiving detection assembly are within the set threshold. The device is advantaged in that the workpieces with unsatisfactory coaxiality, unacceptable straightness and uneven thickness can be detected, the method of projection shading and light sensors are adopted for detection, the detection automation degree is high, the workpieces can be excellently positioned, in addition, a left support roller assembly or a right support roller assembly can further be set to be rotatable, so angles of the workpieces can be adjusted, multi-angle detection of each of the workpieces is realized, and detection accuracy is improved.

Owner:东莞市同圣模具科技有限公司

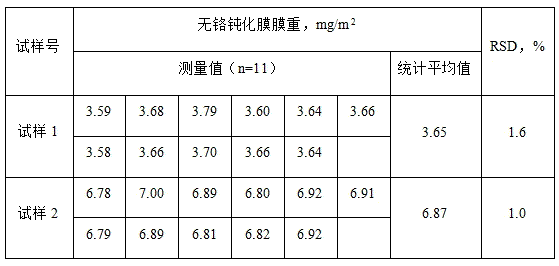

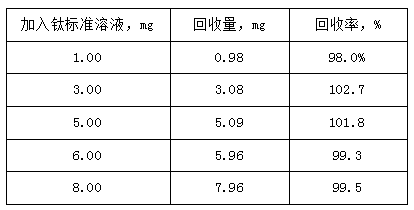

Detection method for weight of chromium-free passivation film on tinplated steel board

InactiveCN106770188ATo achieve accurate weight measurementImprove accuracyAnalysis by thermal excitationChromium freeSheet steel

The invention relates to a detection method for weight of a chromium-free passivation film on a tinplated steel board and mainly solves the technical problem that the weight of the chromium-free passivation film on the tinplated steel board cannot be measured accurately. The method includes the steps of: 1) cutting a test piece in certain area and sealing the edges with an acid-resistant sealing material; 2) placing the test piece in a beaker and adding a dilute sulfuric acid solution, and heating and boiling the dilute sulfuric acid solution for 90-120 s; 3) taking the test piece out, and moving the solution into a 100 ml volumetric flask after the solution is cooled to 15-25 DEG C, diluting the solution to scale by water and shaking the volumetric flask to obtain a to-be-detected solution; and 4) measuring the spectral intensity of titanium in the to-be-detected solution by an inductive coupling plasma emission spectrometer and calculating the weight of the chromium-free passivation film on the test piece. The method is high in accuracy of detection data, has simple operations and low labor intensity, and satisfies accurate measurement on the weight of the chromium-free passivation film on the tinplated steel board.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Autonomous vehicle steering control system

ActiveCN108032903AImprove operational flexibilityIncreased sensitivitySteering linkagesFluid steeringVehicle frameSteering wheel

The invention relates to an autonomous vehicle steering control system, comprising rotation speed sensors, a main angle sensor, auxiliary angle sensors, a steering drive mechanism, a transmission shaft and a controller. The at least two rotation speed sensors and the at least two auxiliary angle sensors are mounted on a wheel axle of vehicle steering wheels. The main angle sensor is connected witha vehicle steering wheel shaft and a steering drive mechanism. The steering drive mechanism is mounted on a vehicle frame and is connected with a vehicle steering drive mechanism and the vehicle steering wheel shaft through a transmission shaft. The controller is installed on the vehicle frame. A use method of the autonomous vehicle steering control system comprises three steps: steering signal acquisition, steering drive and steering correction and the like. The method has the advantages of simple structure, flexibility and convenience in use, convenience in installation and replacement, high detection accuracy and high automation degree of operation, and greatly improves the reliability, convenience and operation accuracy of the steering operation of the vehicle.

Owner:北京鑫洋浩海科技有限公司

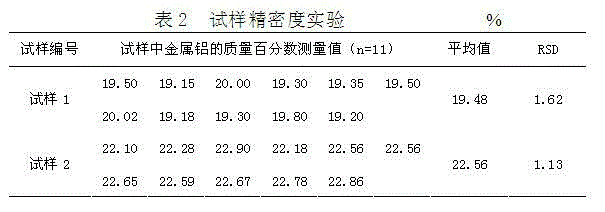

Method for determining content of metal aluminum in ladle slag modifying agent

InactiveCN104422685ASolve the problem of accurate and fast detectionAccurate measurementAnalysis by thermal excitationTest sampleSlag

The invention relates to a method for determining the content of metal aluminum in a ladle slag modifying agent, which mainly aims at solving the technical problems in the prior art that the precision of detection on the content of the metal aluminum in the ladle slag modifying agent is low and the time for detecting the content of the metal aluminum in the ladle slag modifying agent is long. According to the technical scheme, the method for determining the content of the metal aluminum in the ladle slag modifying agent comprises the following steps: measuring a test sample of a fixed quantity, placing the test sample into a tapered bottle with a copper sulfate leaching solution, and heating and boiling the copper sulfate leaching solution by utilizing an electric heating plate so as to selectively dissolve metal aluminum in the test sample, thereby separating the metal aluminum from other elements and aluminum in other forms in the test sample, and preparing a solution to be detected; determining spectral intensity of the aluminum in the solution to be detected by adopting an inductance coupling plasma emission spectrometer; and calculating the content of the metal aluminum in the test sample. By adopting the determination method, the content of the metal aluminum in the ladle slag modifying agent can be accurately measured, and the detection time is short and only needs 2 to 3 hours.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

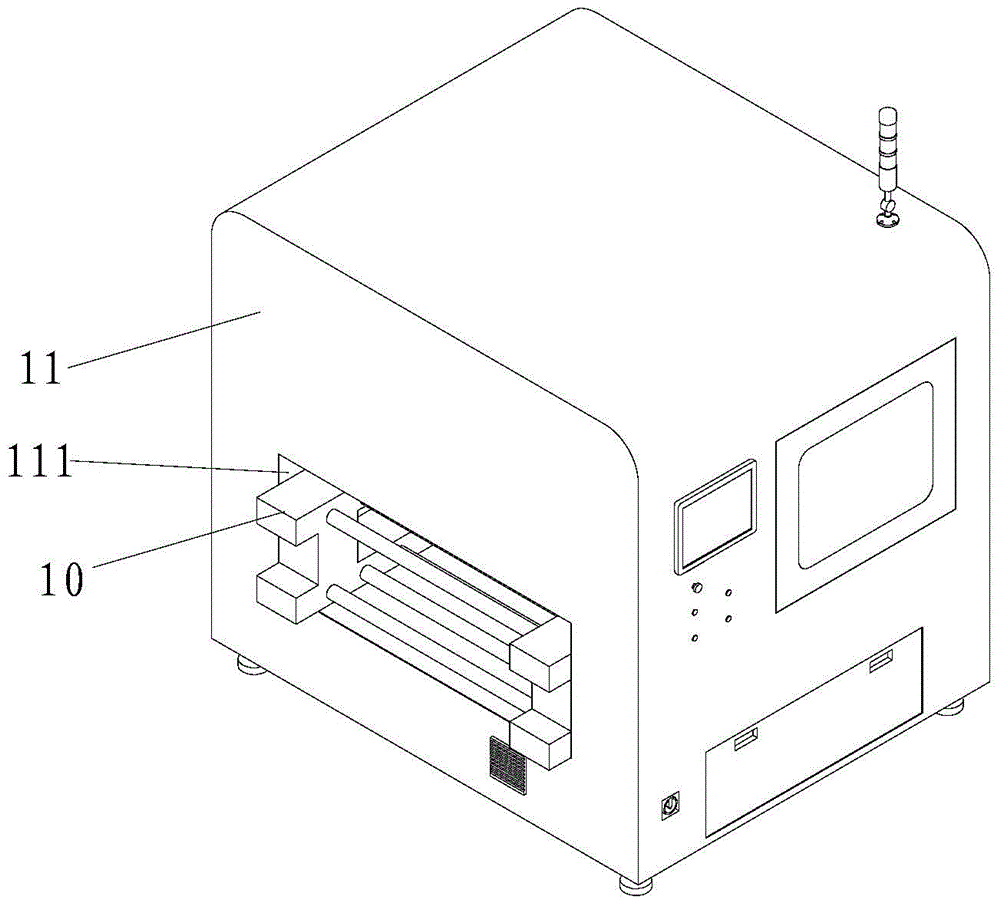

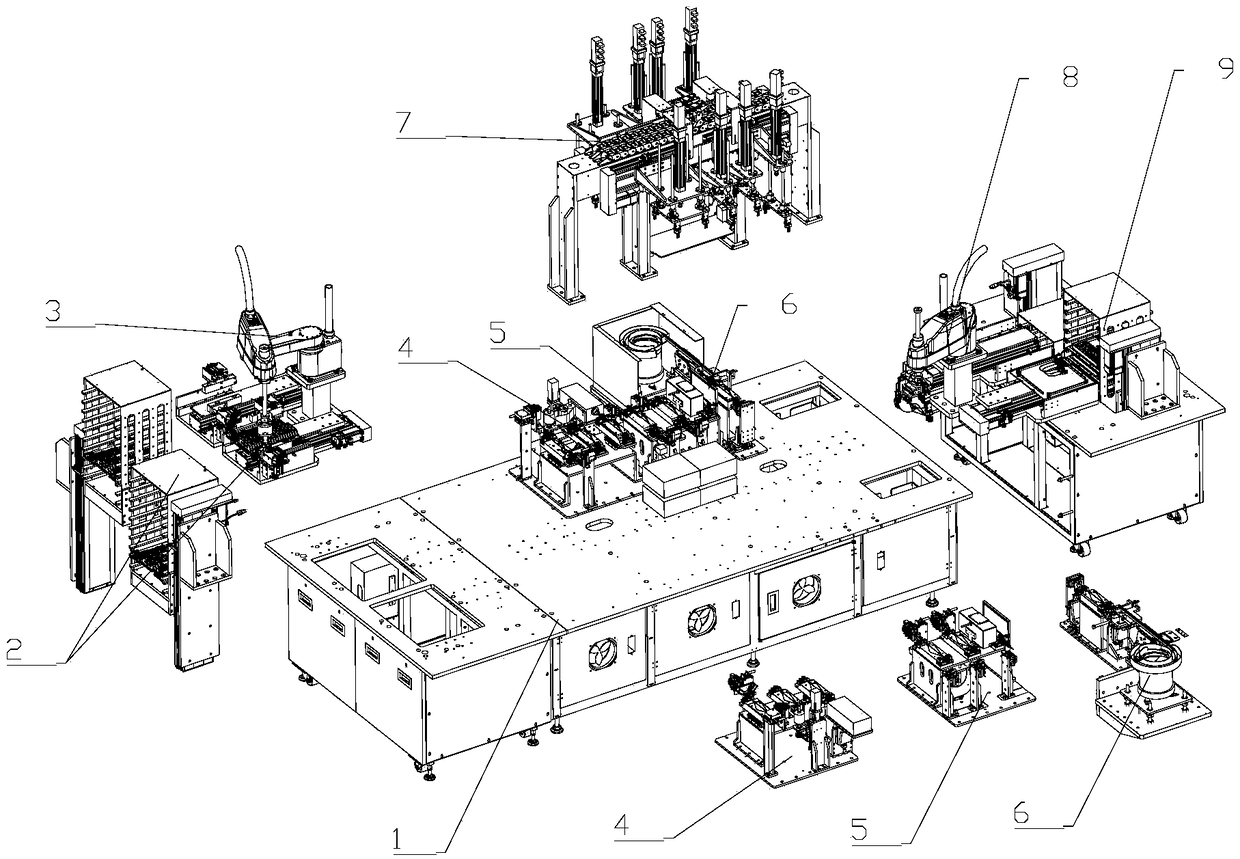

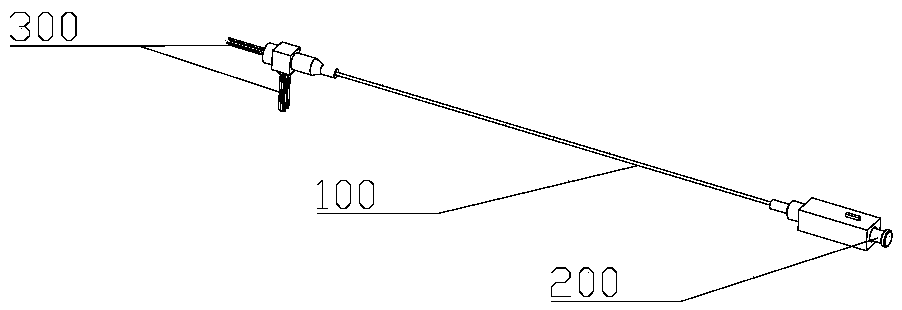

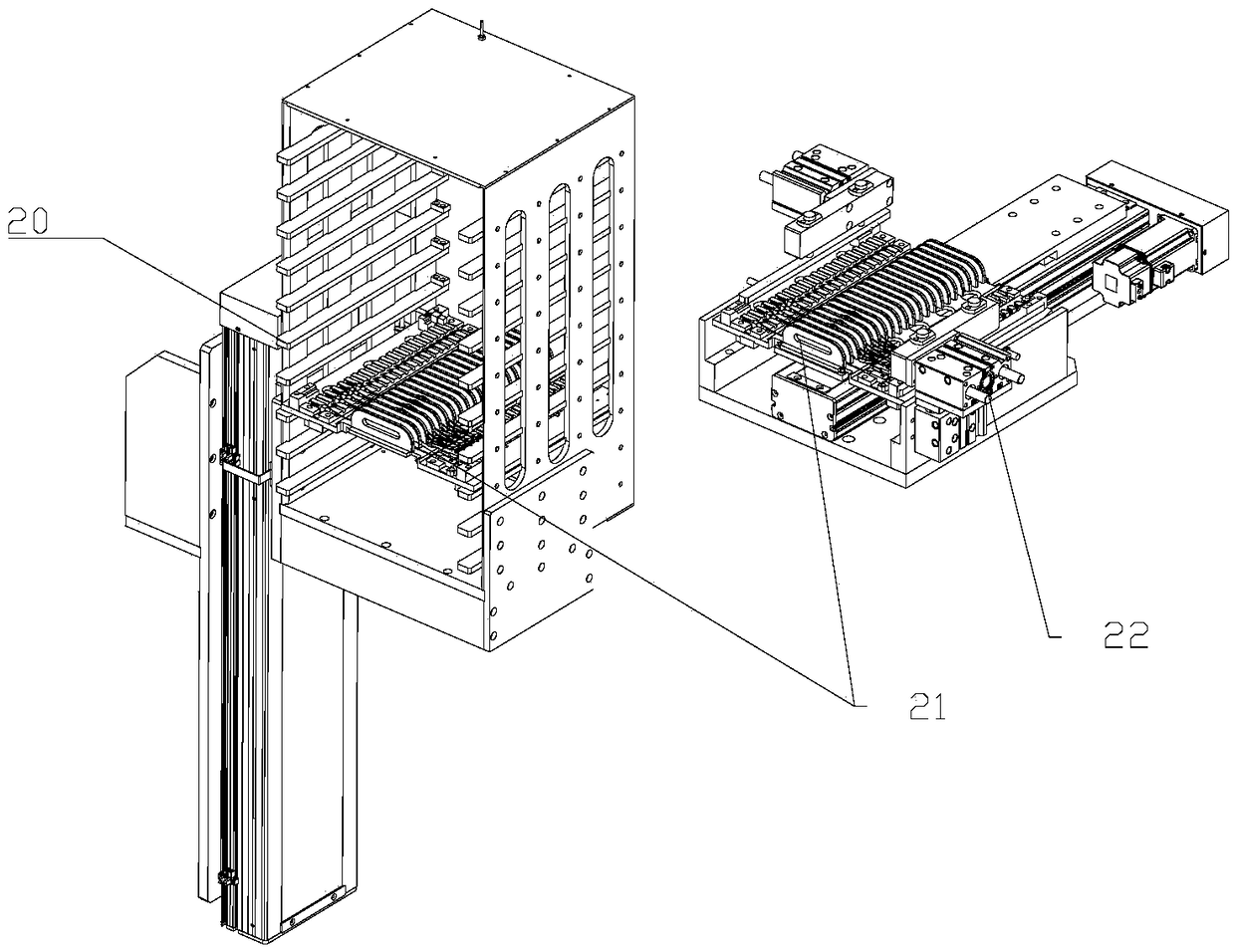

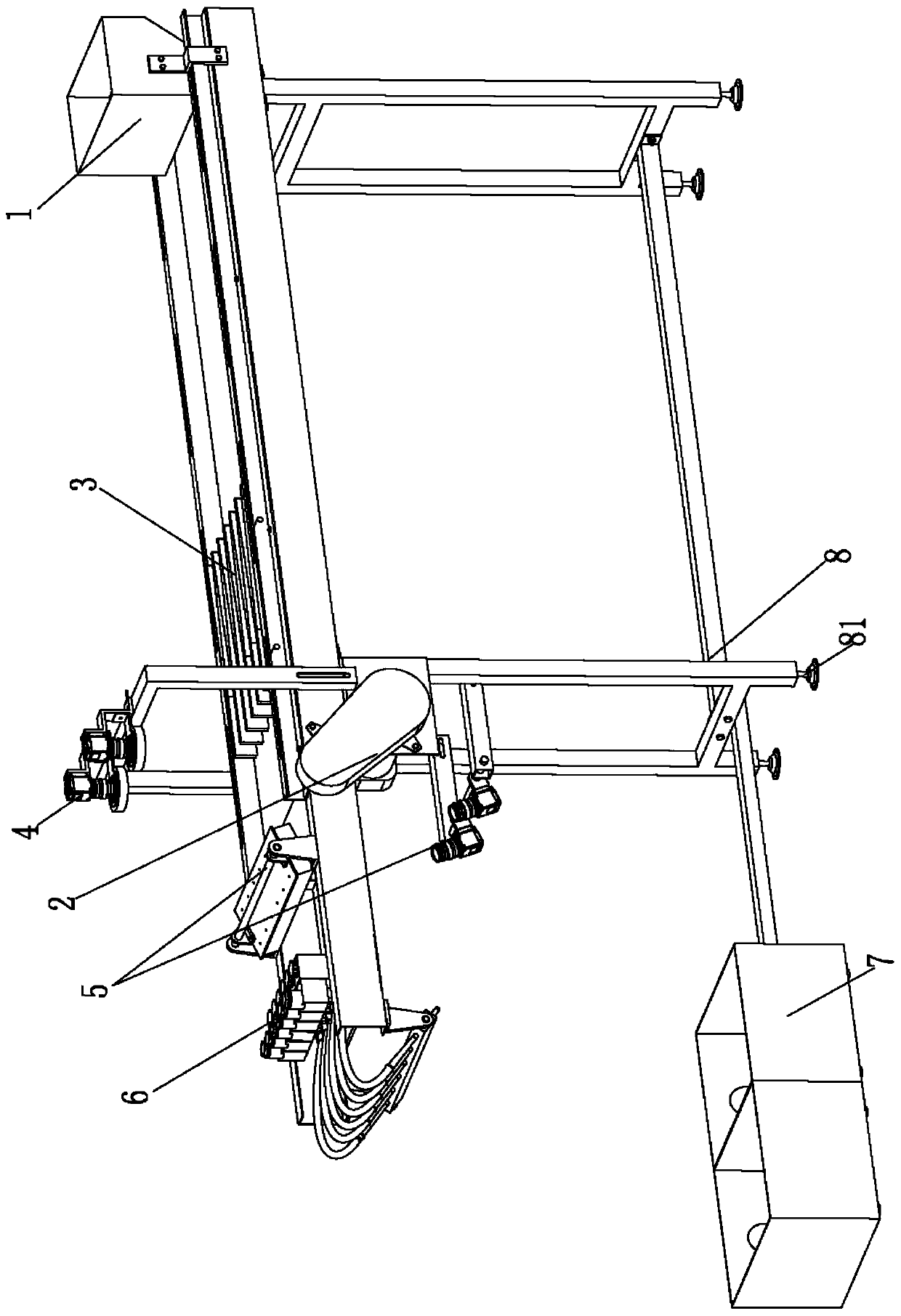

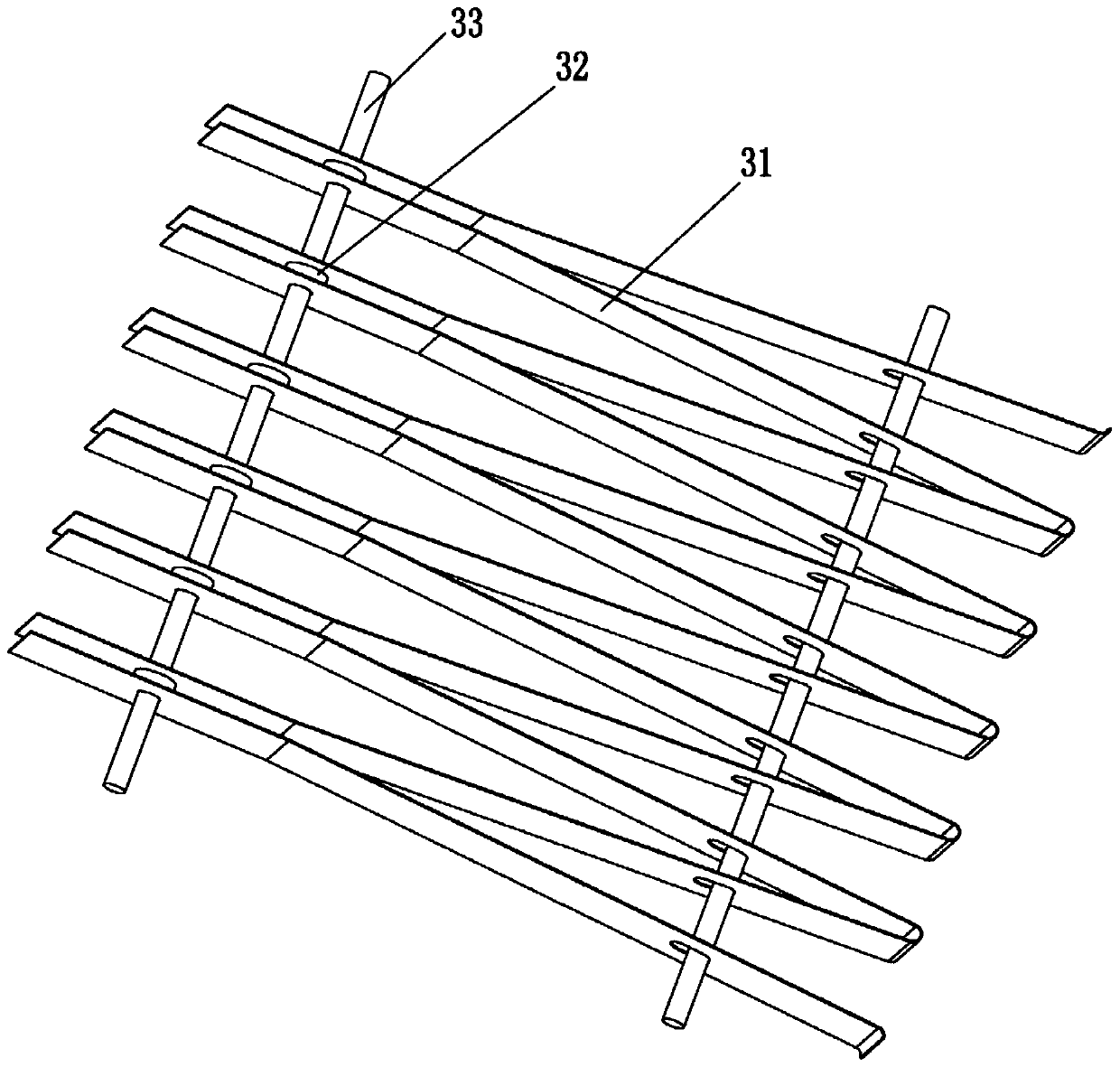

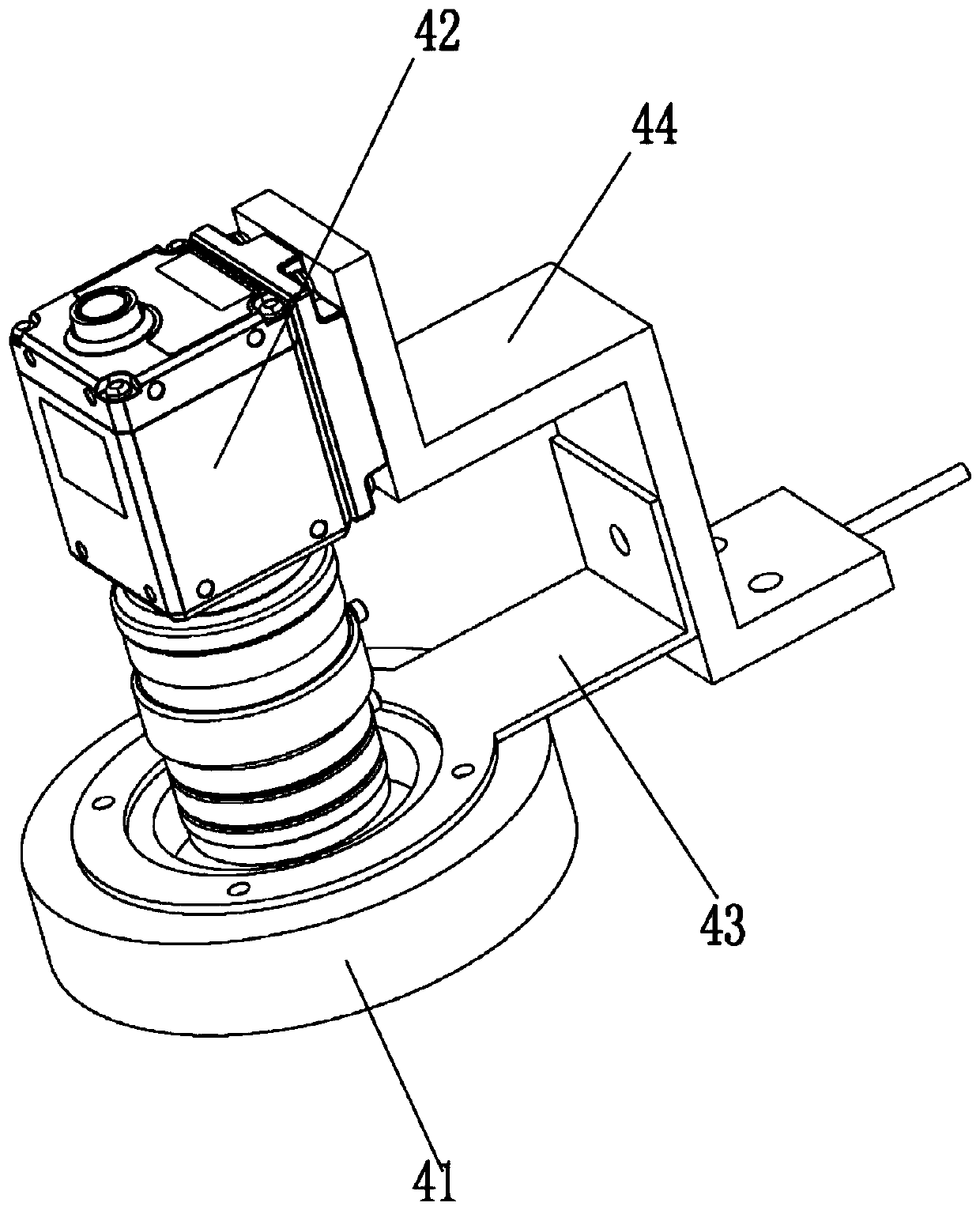

Optical fiber device and detection method and detection equipment thereof

ActiveCN109163885AHigh detection efficiency and automationWide range of testsTesting fibre optics/optical waveguide devicesEngineeringOptical fiber cable

The invention relates to the technical field of communication. A detection method for an optical fiber device comprises the following steps of carrying out feeding, carrying out combing before detection, carrying out detection, assembling a protection cover and carrying unloading. The detection method for the optical fiber device has the advantages that detection efficiency and automation degree are high and a test range is wide.

Owner:ANHUI PENGDA OPTOELECTRONICS TECH CO LTD

Workpiece surface roughness and flatness detection device

InactiveCN114111540AImprove detection efficiencyImprove detection stabilityMechanical roughness/irregularity measurementsSurface roughnessStructural engineering

The invention discloses a workpiece surface roughness and flatness detection device which comprises a supporting frame, a guiding sliding groove, a limiting clamping plate, a material guiding mechanism, a detection mechanism, a connecting workpiece, a threaded rod, a material storage box, a guiding groove, a servo motor, a connecting belt, a connecting belt wheel and a rotating shaft groove. A supporting frame used for supporting is fixedly installed at the position, close to the center, of the upper end face of the material guiding mechanism, and limiting clamping plates are symmetrically and fixedly installed on the lower end face of the supporting frame. By arranging the workpiece template, a connecting workpiece can be compared with a standard part during detection, so that the efficiency and the stability of subsequent detection of the connecting workpiece are improved to the greatest extent, meanwhile, two groups of supporting sliding grooves are formed, two groups of connecting workpieces can be detected at the same time, the speed of detecting the connecting workpiece is effectively improved, and the detection accuracy is improved. And the detection efficiency is improved.

Owner:潘碎斌

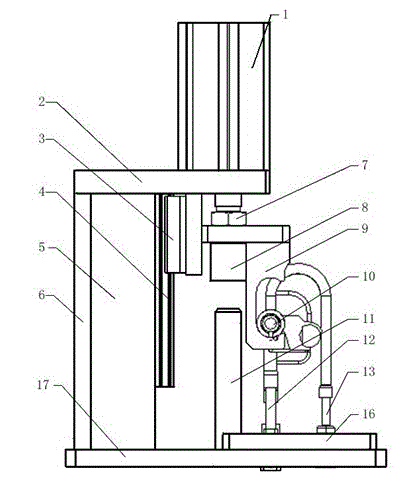

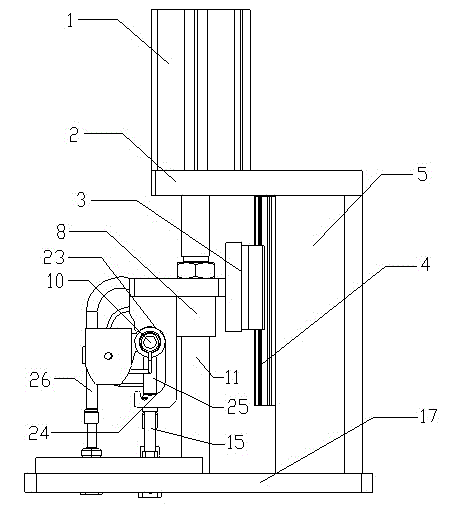

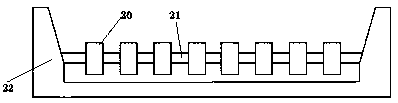

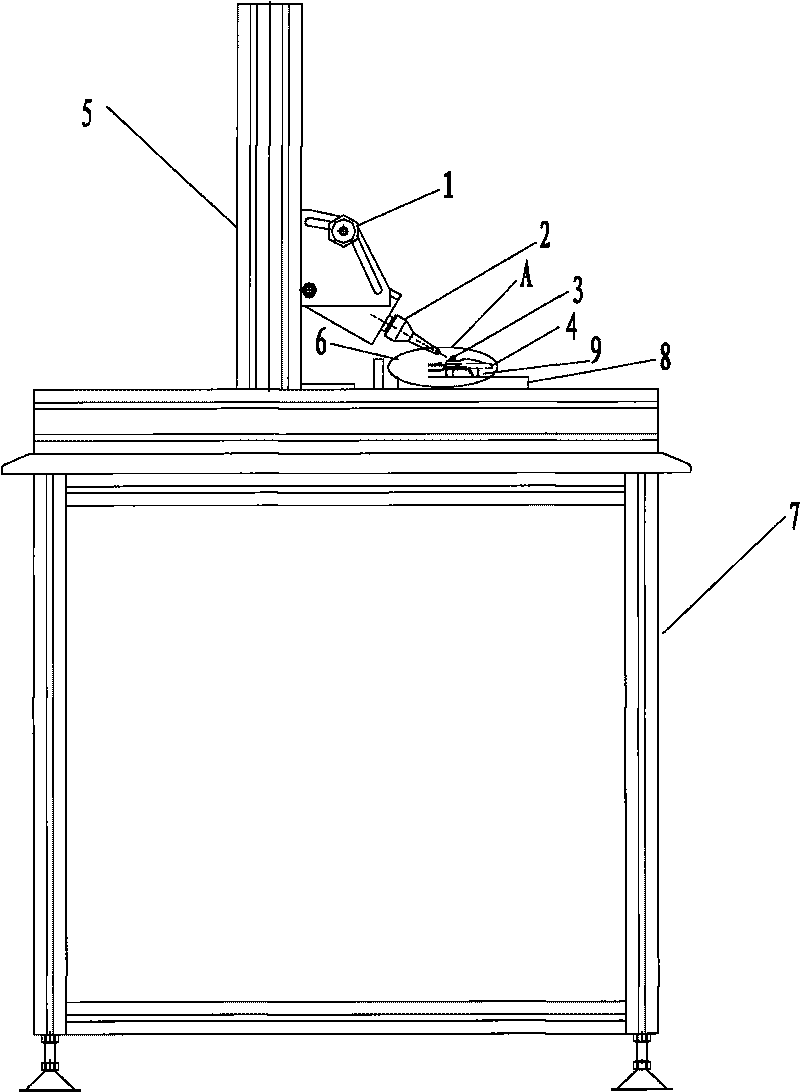

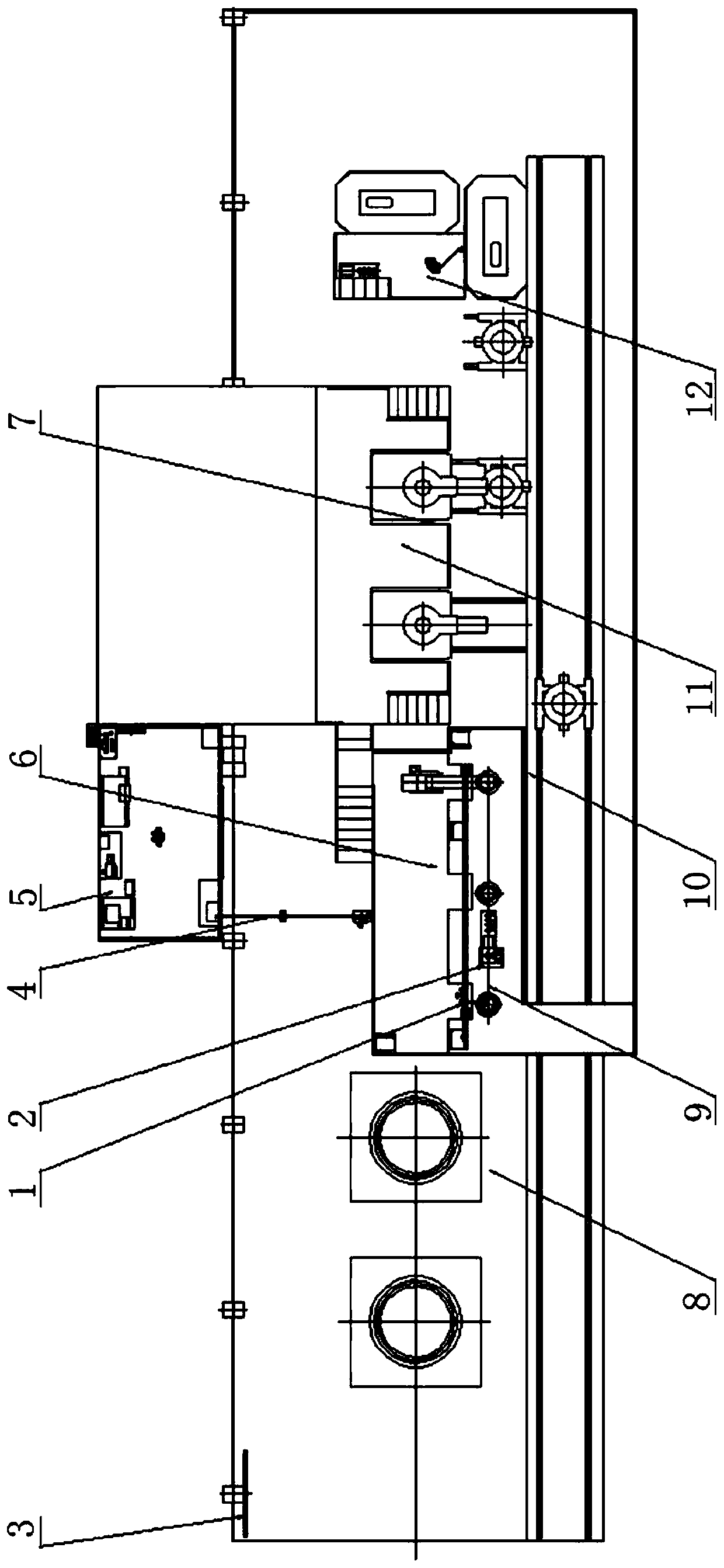

Pulling buckle fatigue test board

InactiveCN101701878ASimple structureHigh detection efficiency and automationStructural/machines measurementAutomatic controlEngineering

The invention discloses a pulling buckle fatigue test board which comprises an angle adjuster arranged on a base, a push rod, cylinder fixing rods, a first cylinder, a fixing plate, a pulling buckle fixing plate, a second cylinder, a cylinder adjustment device and an automatic control device, wherein the second cylinder is arranged between the cylinder fixing rods through the cylinder adjustment device; the push rod is connected with the second cylinder through the angle adjuster; the first cylinder is fixed on the upper part of the base; and the pulling buckle fixing plate is fixed on the base through the fixing plate and arranged opposite to the push rod and the first cylinder. The invention has simple structure and high detection efficiency and automation degree.

Owner:JIANGSU LUCKY BABY SAFETY SYST MFG

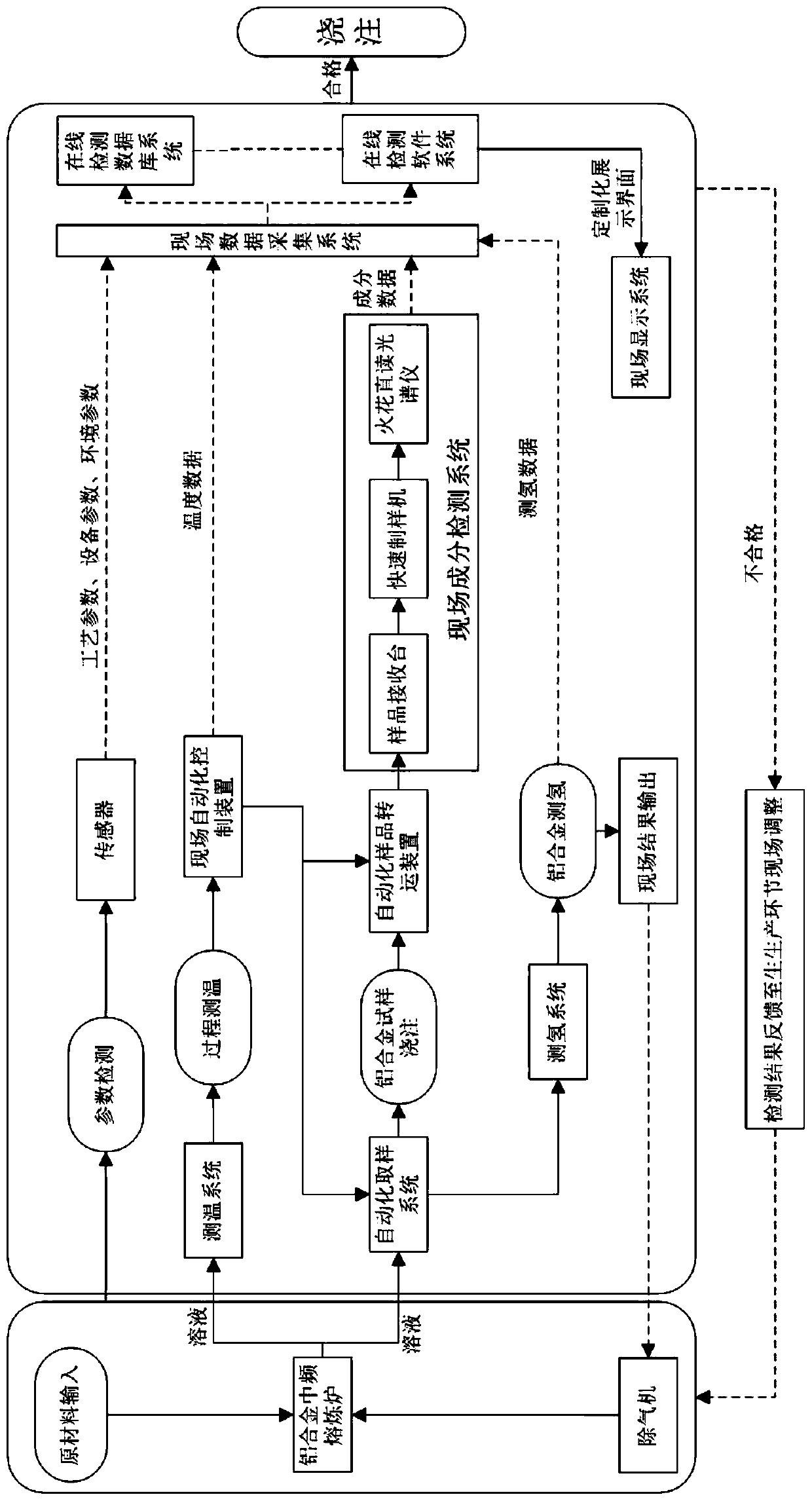

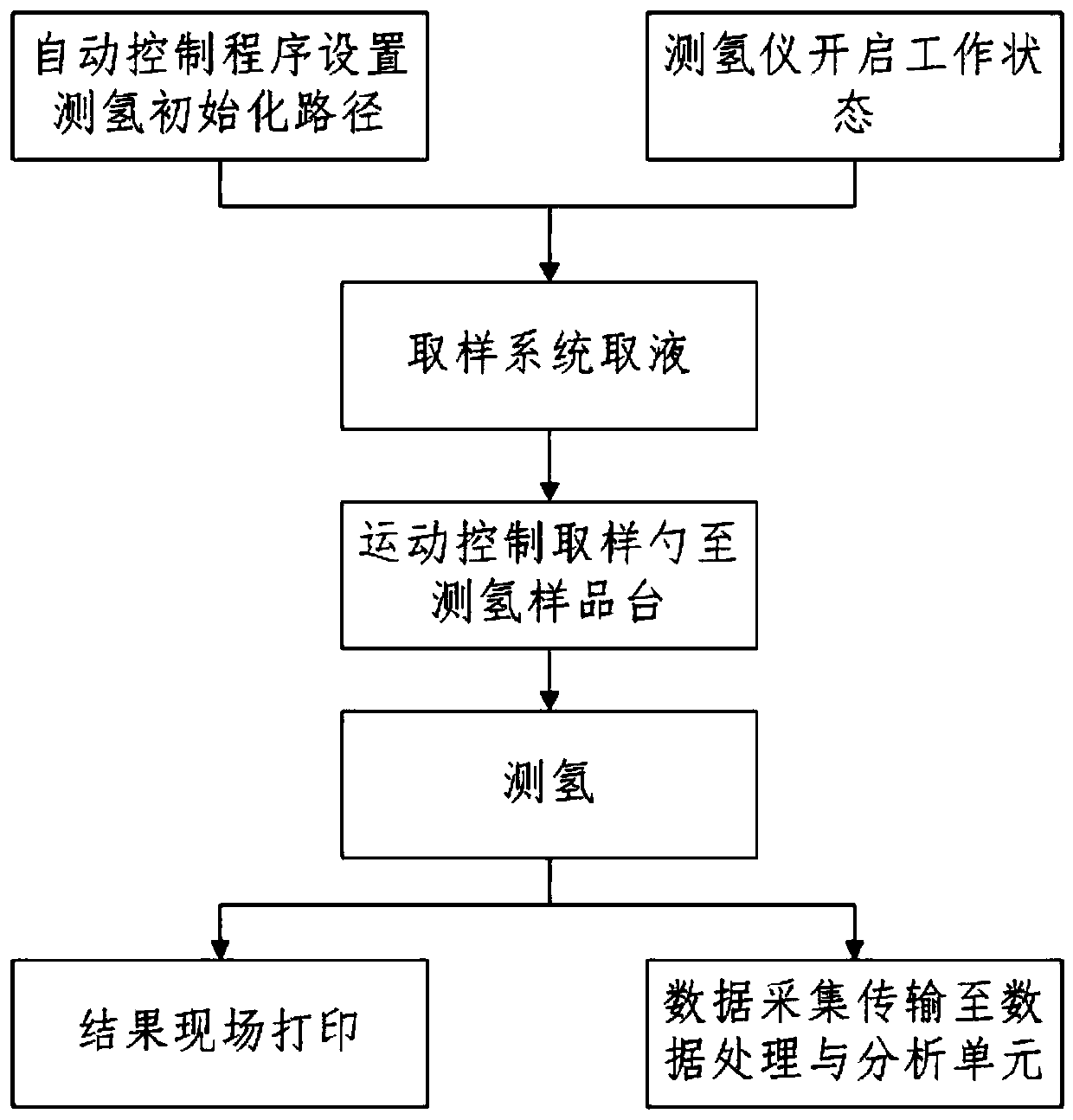

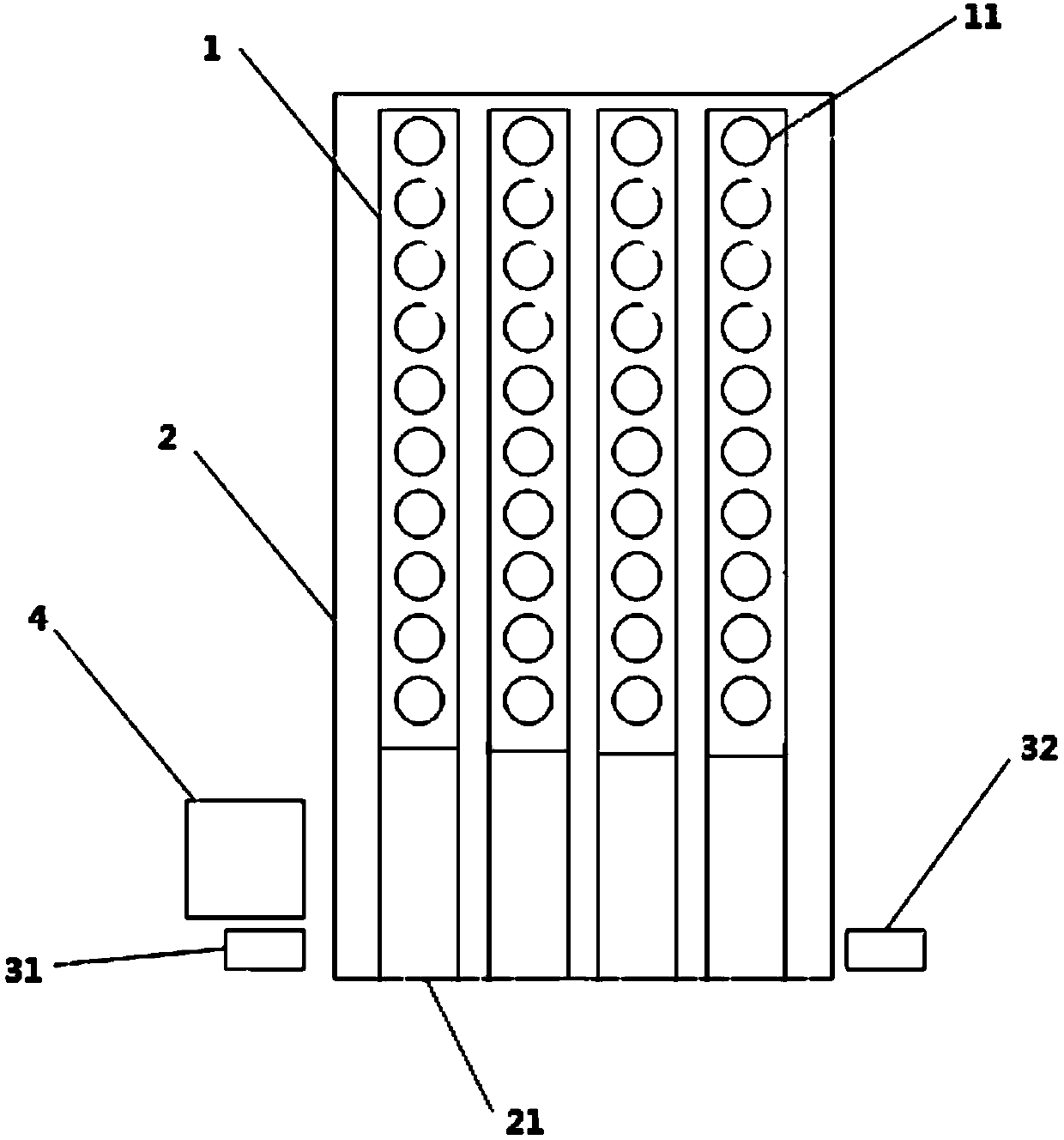

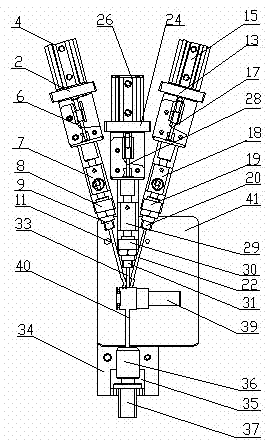

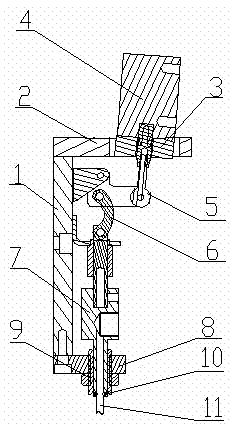

Aluminum alloy casting and smelting process online detection and data application method and system

InactiveCN110362047AQuick captureShort detection cycleTotal factory controlProgramme total factory controlSmelting processChemical element

The invention discloses an aluminum alloy casting and smelting process online detection and data application method and system. The online detection and data application method comprises the steps: A,sampling a solution and sending the sample solution to a hydrogen measuring system and pouring area; B1, measuring the hydrogen content in the sample solution, displaying the result and determining whether to perform secondary degassing refining; B2, sending the pouring sample to a field composition detection system, wherein the field composition detection system detects the chemical element composition in the pouring sample, displays the result and determines whether the chemical element composition needs to be adjusted; and C, performing temperature measurement on the casting and melting process of the aluminum alloy, displaying the result and determining whether the temperature needs to be adjusted. The method is applied to the casting and melting process of the aluminum alloy, the detection automation degree is high, the detection period of key parameters is short, the data result is stable and reliable and the practical value of production and application is high; the casting andsmelting process of the aluminum alloy is always controlled, the product quality and reliability are improved and the production efficiency is high.

Owner:湖南航天天麓新材料检测有限责任公司

Recognition device for test tube

PendingCN108052850AReduce manual interventionAvoid misuseSensing by electromagnetic radiationTest tube stands/holdersComputer moduleIdentification device

The invention provides a recognition device for a test tube. The recognition device comprises at least one test tube, at least one test tube rack, and a scanner. The test tube rack comprises at leastone test tube accommodating part. The recognition device is characterized by also comprising a test tube detection position assembly and a group of optical fiber detection facilities. The test tube detection position assembly comprises at least one group of test tube position modules. The recognition device also comprises a control module. The control module is electrically connected to the optical fiber detection facilities, the test tube position modules, and the scanner. When the test tube rack is pushed along a slot, the test tube rack is completely stored in the test tube detection position assembly, and based on the electric property judging label and the position information of the test tube, correlation between the position information and the memory information is established andstored. The test tube detection efficiency and automation degree are improved.

Owner:ANPAC BIO MEDICAL SCI (LISHUI) CO LTD

Pilot valve air tightness testing device

InactiveCN102539076AHigh degree of detection automationReduce labor costsPipe elementsFluid-tightness measurement using fluid/vacuumMechanical constructionEngineering

The invention discloses a pilot valve air tightness testing device, which comprises a high-pressure air inlet mechanism of a tube E, a closing mechanism of a tube S, a high-pressure air inlet mechanism of a tube C, a closing mechanism of a tube D and a stainless steel reflector. The high-pressure air inlet mechanism of the tube E, the closing mechanism of the tube S, the high-pressure air inlet mechanism of the tube C and the closing mechanism of the tube D are respectively connected with the tube E, the tube S, the tube C and the tube D of a pilot valve, and the stainless steel reflector is mounted right below the pilot valve. The pilot valve air tightness testing device is high in detection automation degree, realizes automation of sealing processes of the various tubes of the pilot valve, saves labor cost and improves testing efficiency; before air tightness is detected, a mechanical structure is used for applying force onto an O-shaped ring and leads the O-shaped ring to deform, so that the sealing effect of the various tubes is good, and testing precision is guaranteed; the stainless steel reflector is mounted and brings convenience for an operator to observe the condition of air leakage of the lower half portion of the pilot valve, and reliability of test results is improved; and the pilot valve to be detected is soaked into water or raised from the water by the mechanical structure, so that detection time is greatly shortened.

Owner:CHINA JILIANG UNIV

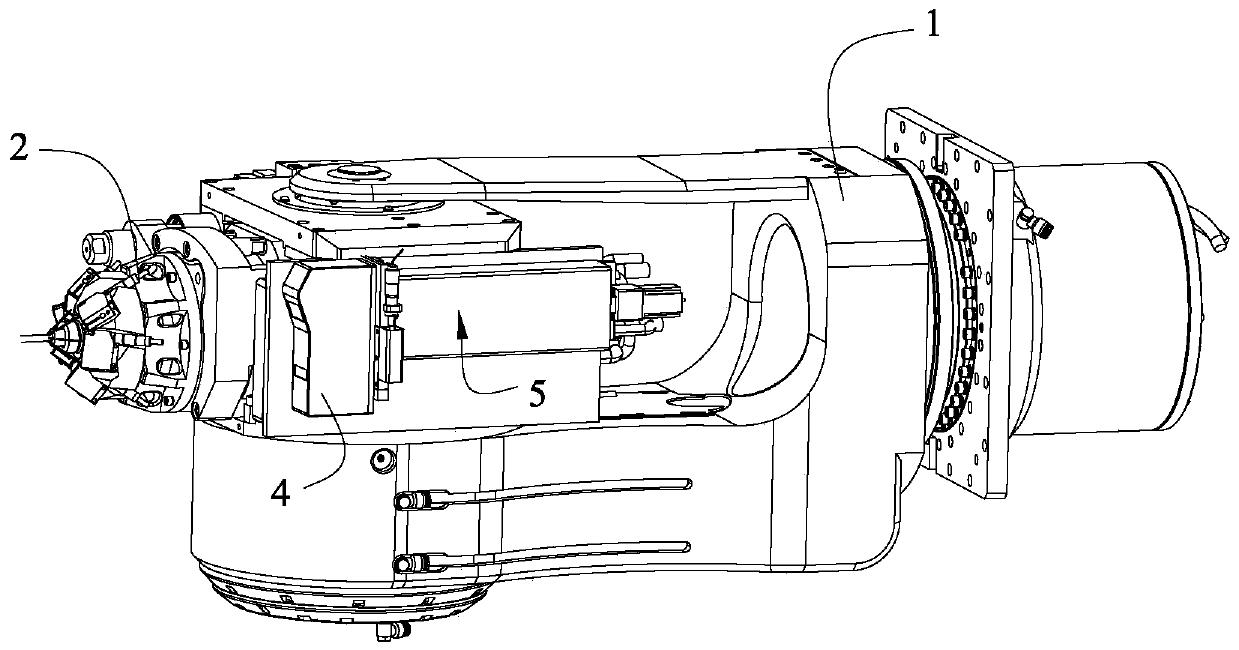

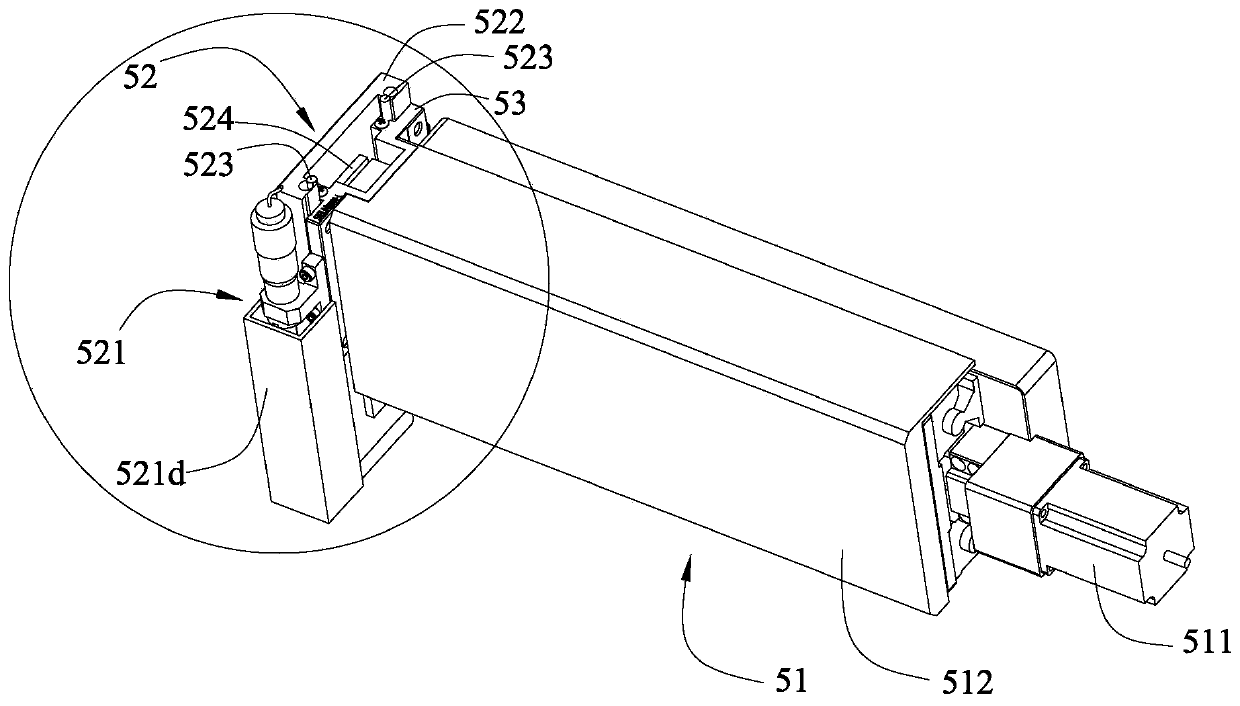

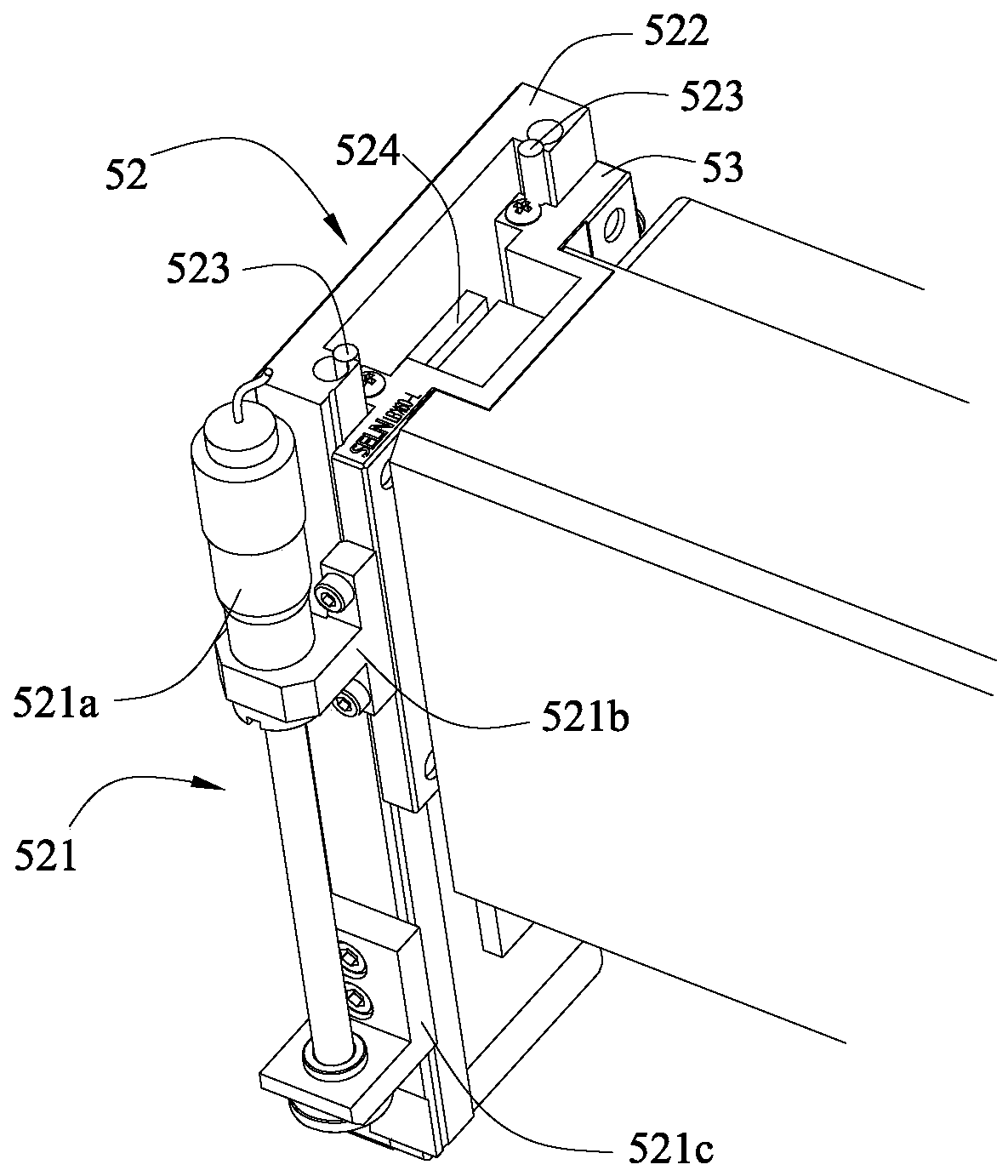

Multifunctional integrated aviation assembly hole making system and application method thereof

ActiveCN111496289AAvoid bulky and bulky problemsAvoid transfer tasksDrilling/boring measurement devicesUsing optical meansAviationNumerical control

The invention provides a multifunctional integrated aviation assembly hole making system and an application method thereof. The multifunctional integrated aviation assembly hole making system comprises a multi-axis numerical control motion mechanism, a hole making device, a multi-axis numerical control motion control system, a line laser scanning sensor, a scanning motion mechanism, a scanning motion mechanism control system, an image processing workstation. The system is simple in structure and high in degree of integration, the requirements of aircraft skin skeleton bonding surface detection, prefabricated hole position acquisition and hole making quality detection can be met through only a set of line laser scanning sensor, the problem that a working head is bulky and is too large in size due to the fact that various sensors are assembled on the working head is solved, the task of transferring stations between various measuring instruments is further avoided, and the detection accuracy and degree of automation are improved.

Owner:TSINGHUA UNIV

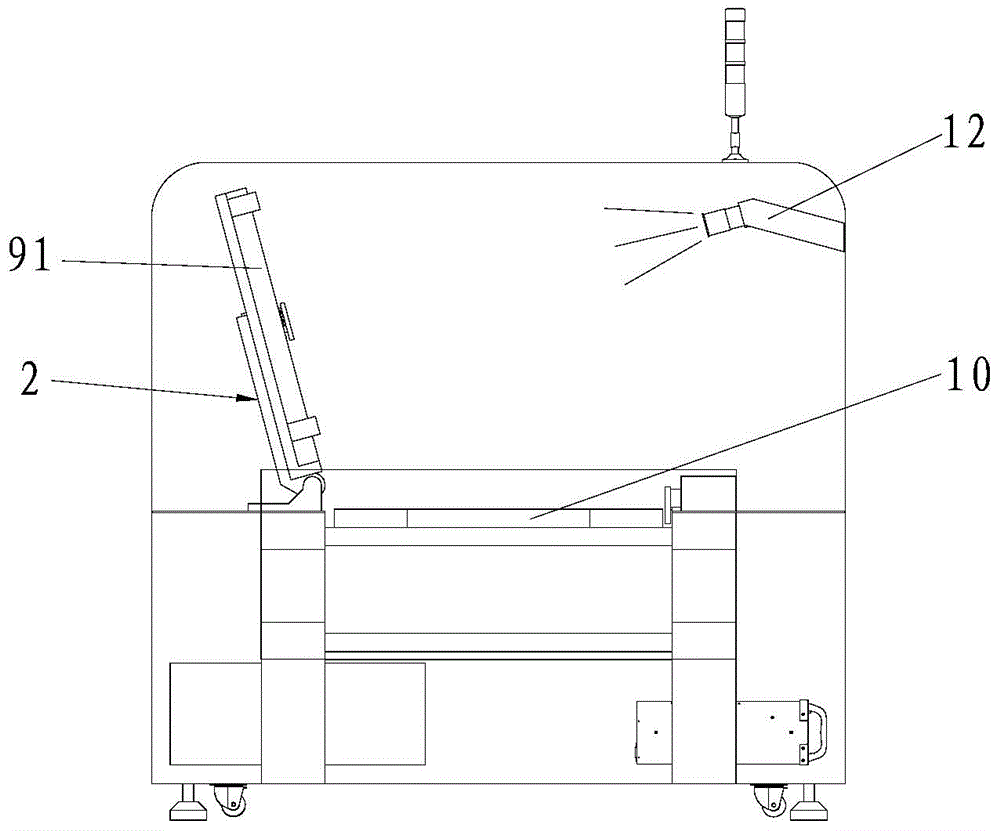

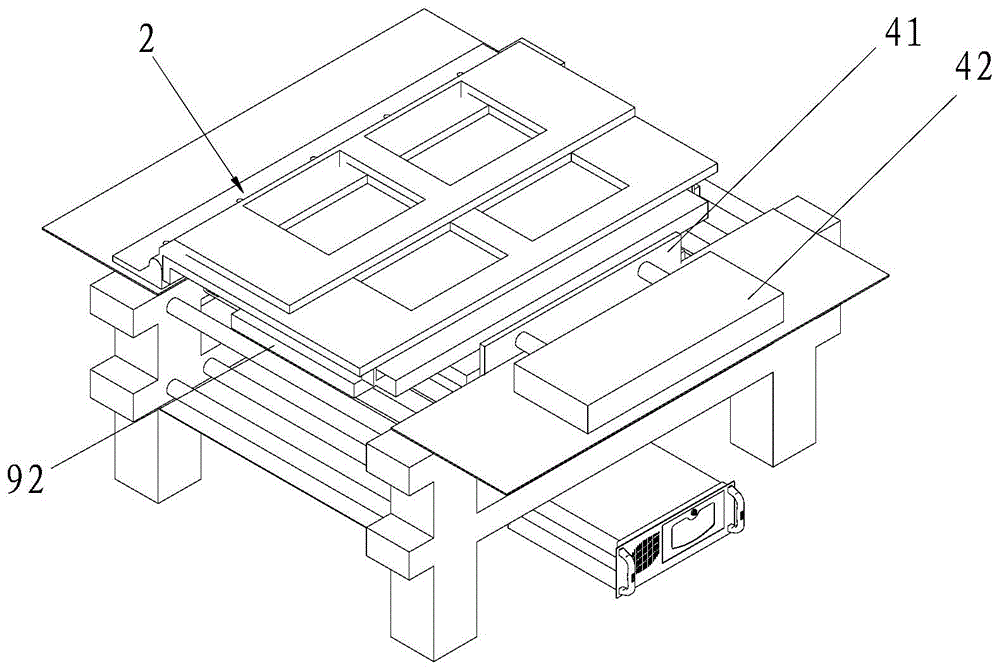

Capsule defect shot blasting full-inspection device

The invention relates to a capsule defect shot blasting full-inspection device. The capsule defect shot blasting full-inspection device comprises a supporting frame, a feeding device, a motor and transmission chain, a belt conveying device, a first image acquisition device, second image acquisition devices, an air injection removing device and a collecting device, wherein the feeding device, the motor and transmission chain, the belt conveying device, the first image acquisition device, the second image acquisition devices, the air injection removing device and the collecting device are arranged on the supporting frame; the feeding device is located above one end of the belt conveying device; the motor and transmission chain is connected with and drives the belt conveying device; the first image acquisition device is arranged above the middle part of the belt conveying device, and the air injection removing device is arranged above the other end of the belt conveying device; the second image acquisition devices are located between the first image acquisition device and the air injection removing device, and are located on the upper side and the lower side of the belt conveying device correspondingly; and the collecting device is located on one side of the supporting frame, and is located below the other end of the belt conveying device. The capsule defect shot blasting full-inspection device has the advantages of being capable of realizing top-and-bottom all-dimensional detection of a capsule, comprehensive in detection, high in detection efficiency and automation degree,convenient to adjust and wide in adaptive variety.

Owner:ZHEJIANG SCI-TECH UNIV

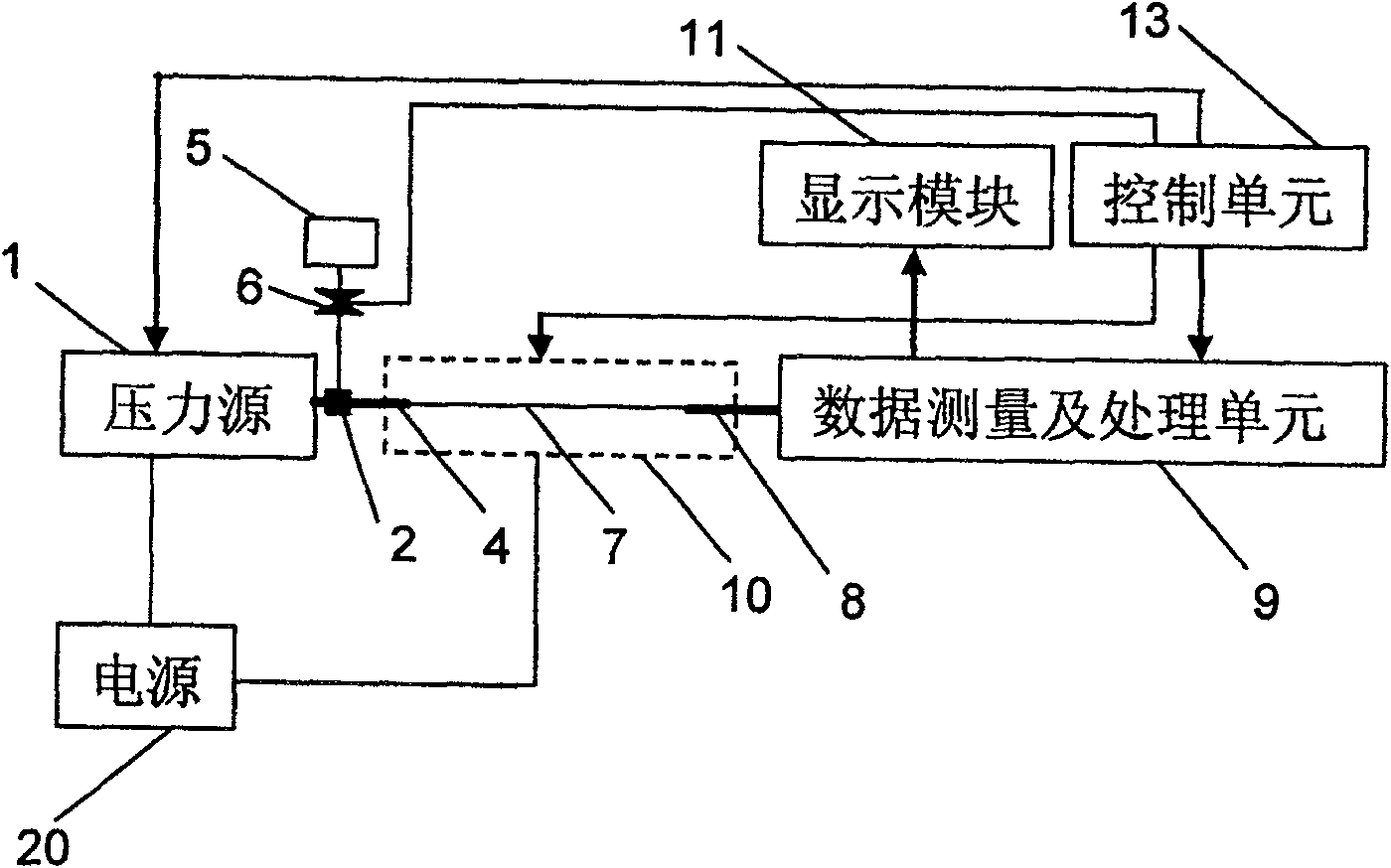

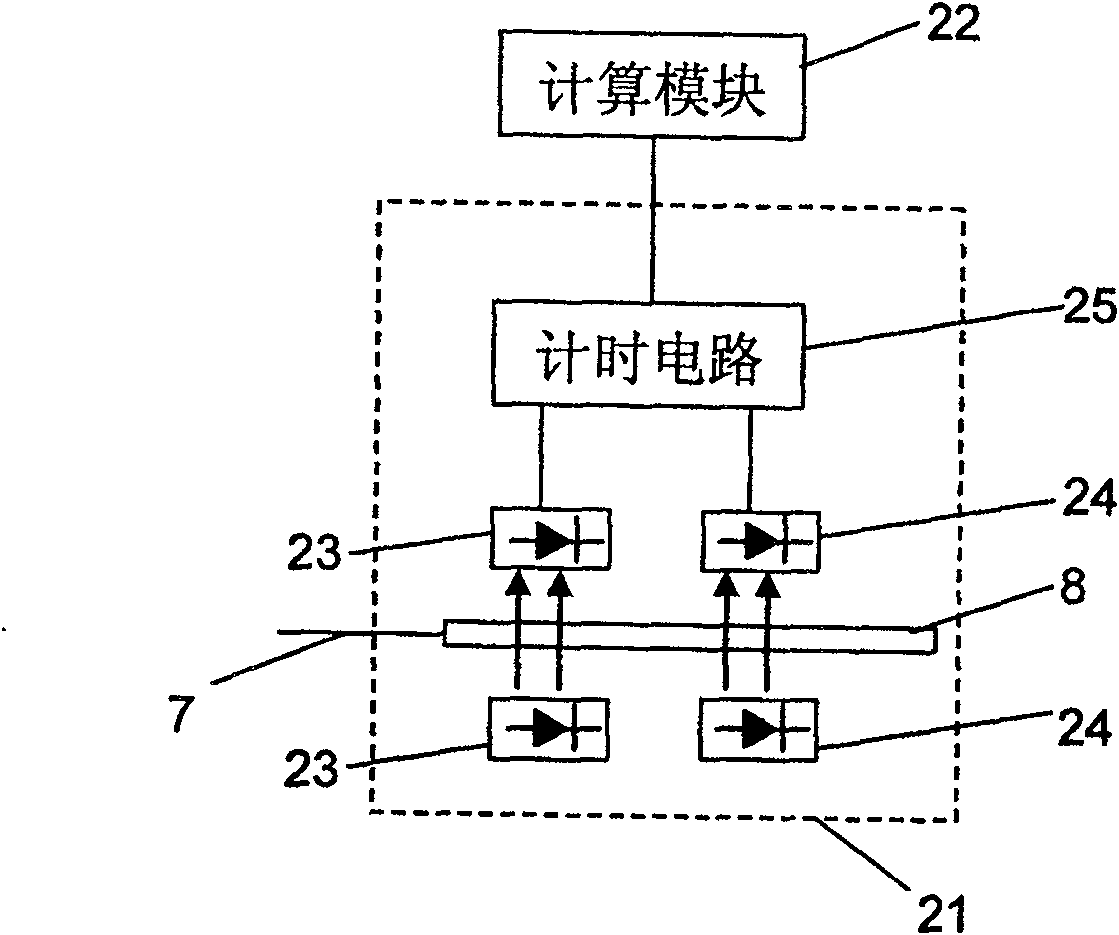

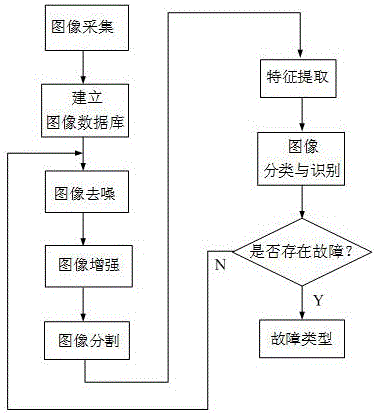

Real-time body blood viscosity measuring instrument

InactiveCN100549695CImprove detection accuracyHigh degree of detection automationBiological testingDirect flow property measurementMeasuring instrumentPediatrics

The invention relates to a measuring instrument for detecting the viscosity of human blood in real time. The measuring instrument includes a pressure source, an infusion tube, a micrometer tube, a transparent capillary, a calibration liquid container containing calibration liquid, a temperature control unit, a data measurement and processing unit, a display module, and a control unit; the transparent capillary is inside the data measurement and processing unit. , and the viscosity was measured using the relative measurement method. The measuring instrument for real-time detection of human blood viscosity of the invention can eliminate operation and reading errors, and has high detection accuracy and automation; the blood volume is small, and only about 20ul of blood can be used for measurement; Sexual use to avoid infection; simple operation, easy to carry, suitable for clinical use in hospitals or ordinary households to detect human blood viscosity.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

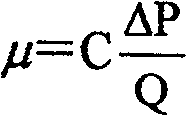

Application of visual information to electrical equipment monitoring

InactiveCN106355187AGuaranteed safe operationLow costCharacter and pattern recognitionImaging FeaturePower equipment

The invention discloses application of visual information to electrical equipment monitoring. The application of the visual information to electrical equipment monitoring includes the steps of firstly, acquiring electrical equipment images and establishing an electrical equipment image database; subjecting the images to preprocessing such as denoising and enhancement; then, subjecting the image to segmentation processing so as to extract image features; finally, conducting fault judgment through image classification and recognition so as to confirm whether electrical equipment has faults or not as well as fault classifications. The application of the visual information to electrical equipment monitoring has the advantages that multiple kinds of algorithms are integrated, a system is of real-time performance, dynamicity, high intelligent level and the like, accidents and economic loss caused by the faults of the electrical equipment are reduced technically, and safe running of the electrical equipment is guaranteed.

Owner:XIHUA UNIV

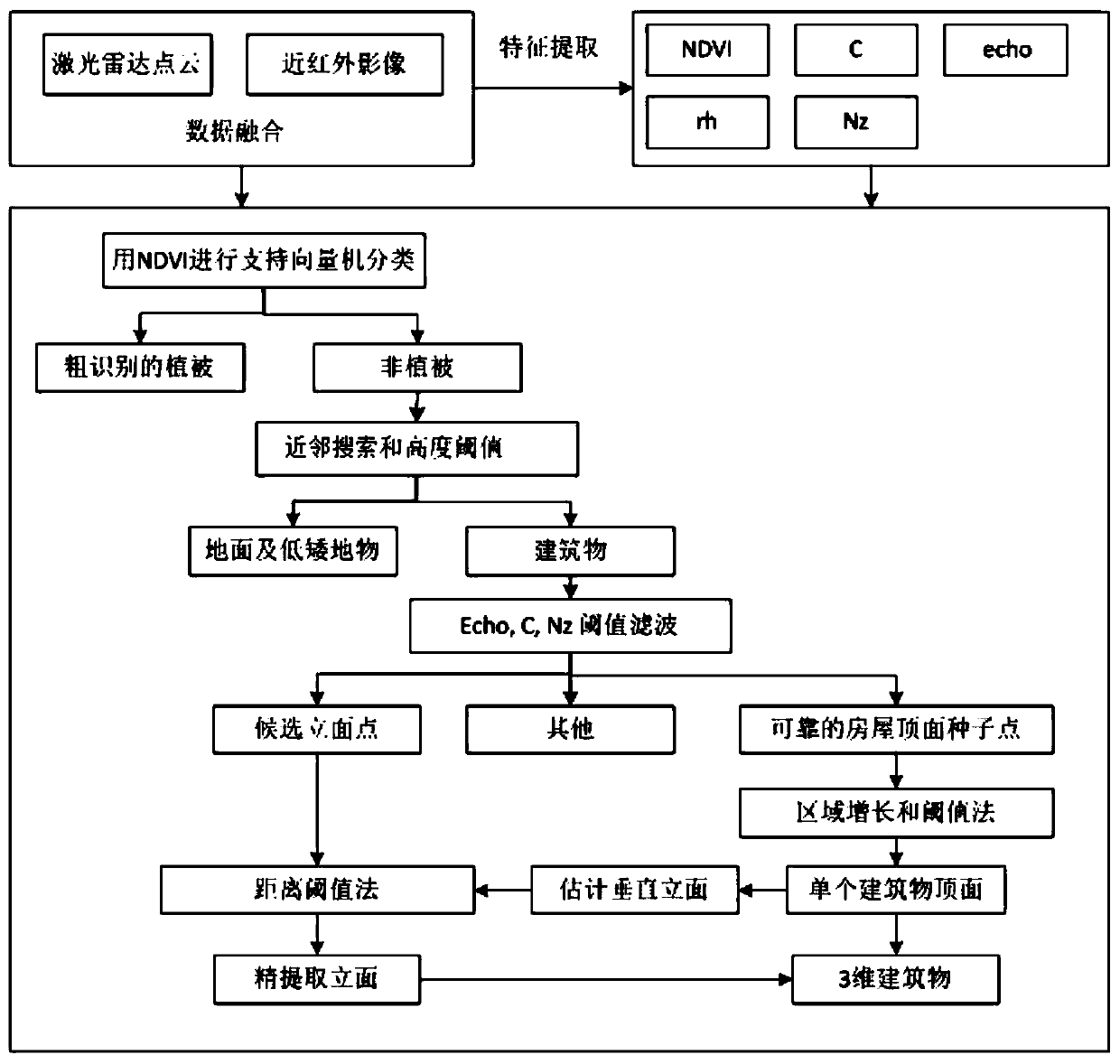

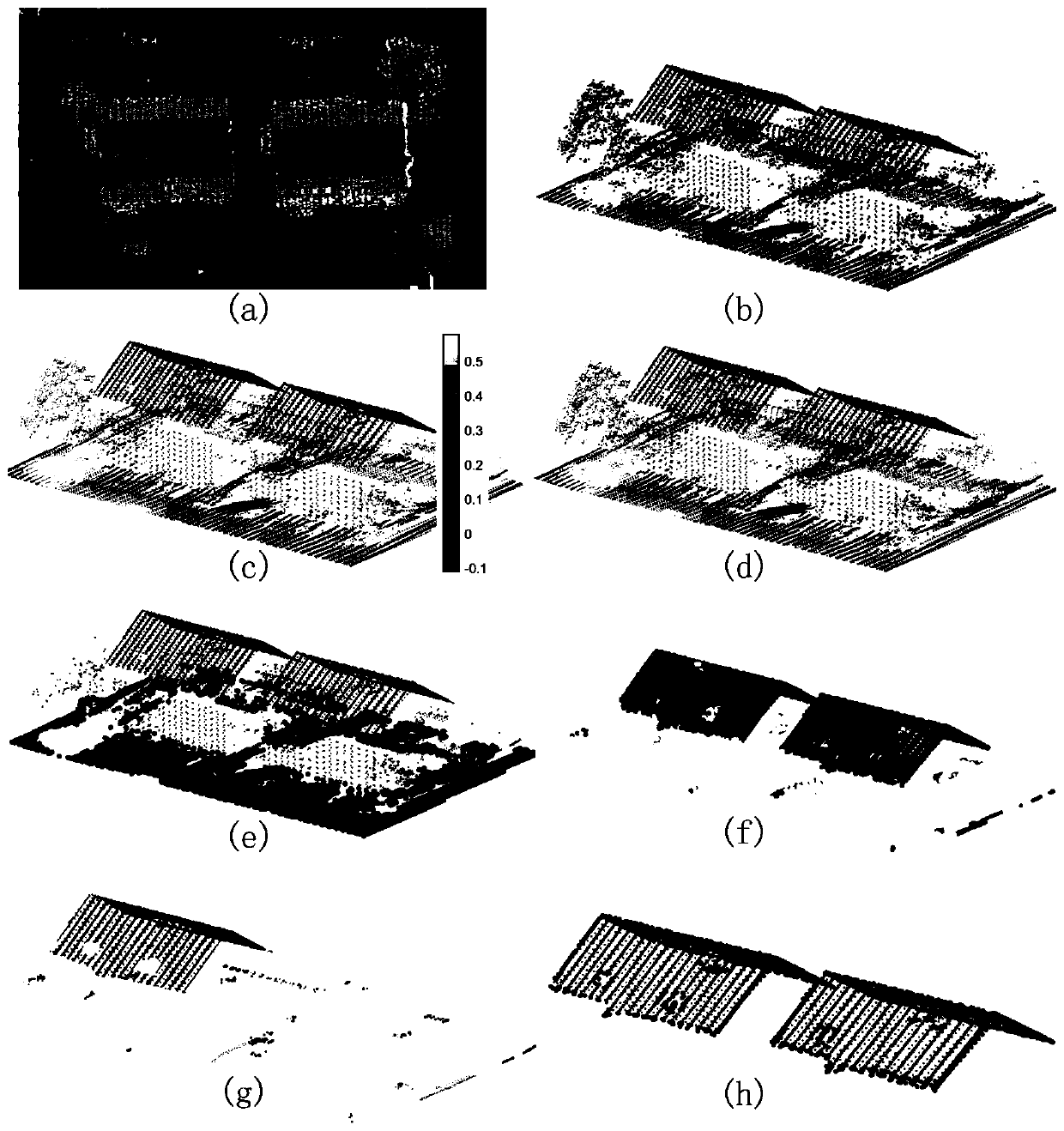

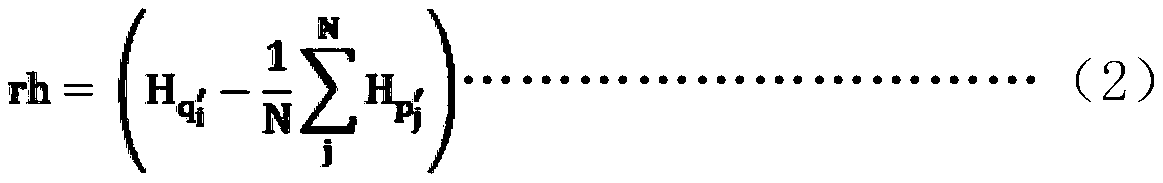

Building detection method based on laser radar point cloud and near-infrared image

ActiveCN111487643AImprove Segmentation AccuracyIncrease the level of detailCharacter and pattern recognitionElectromagnetic wave reradiationSupport vector machine classifierEngineering

The invention discloses a building detection method based on a laser radar point cloud and a near-infrared image. The method comprises the steps: obtaining an ortho-image with a near-infrared band andthe laser radar point cloud, and carrying out the registration and fusion of the ortho-image and the laser radar point cloud; calculating a normalized difference vegetation index NDVI of each laser point after fusion, and completing vegetation identification based on the NDVI and a support vector machine classifier; as for non-vegetation laser points, completing building recognition through a neighbor search algorithm and a height threshold value; as for the building laser points, extracting roof seed points and candidate facade points, and obtaining a roof point group based on a single building according to the roof seed points; estimating the vertical facade of the building based on the roof point group of each building; estimating a vertical facade based on the candidate facade points,and performing fine extraction of the facade points; and completing the detection of the three-dimensional building through the roof points and the facade points obtained through fine extraction. Thedetection precision of the building is effectively improved, and the high detail level of the building model can be ensured.

Owner:AEROSPACE INFORMATION RES INST CAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com