Method for determining content of metal aluminum in ladle slag modifying agent

A determination method and metal aluminum technology are applied in the field of chemical analysis of steel-making raw and auxiliary materials, which can solve the problems of low detection accuracy and long detection time of metal aluminum content, and achieve the effects of high degree of detection automation, simple operation and reduced use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for assaying metal aluminum content in a ladle slag modifier, comprising the following steps:

[0025] a. Weigh 200g of copper sulfate and dissolve it in 1000ml of dilute sulfuric acid solution (1+4) to prepare a leaching solution with a copper sulfate concentration of 20%. Weigh 0.25g of the sample and place it in a 300ml Erlenmeyer flask, add 50ml of copper sulfate The leaching solution was boiled for about 25 minutes with an electric heating plate with a model of SC-404 and a power of 2.4KW. After the soluble sample was completely dissolved, it was removed and cooled to room temperature, and the volume was fixed in a 100ml volumetric flask, and the filtrate was obtained by dry filtration with fast filter paper;

[0026] B, be that the iCAP6300 inductively coupled plasma emission spectrometer measures the aluminum spectral intensity I in the filtrate obtained in the wavelength 308.22nm step a with the model Al ;

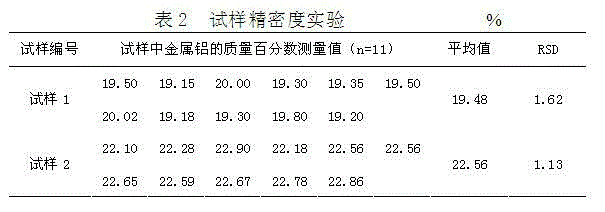

[0027] c. Calculate the metal aluminum conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com