Aluminum alloy casting and smelting process online detection and data application method and system

An application method and application system technology, applied in the field of online detection and data application methods and systems in the aluminum alloy casting and smelting process, can solve the problems of long detection cycle of key parameters, low degree of automation, weak data management, etc., and achieve stable data results Reliable, high degree of automation, the effect of reducing product quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

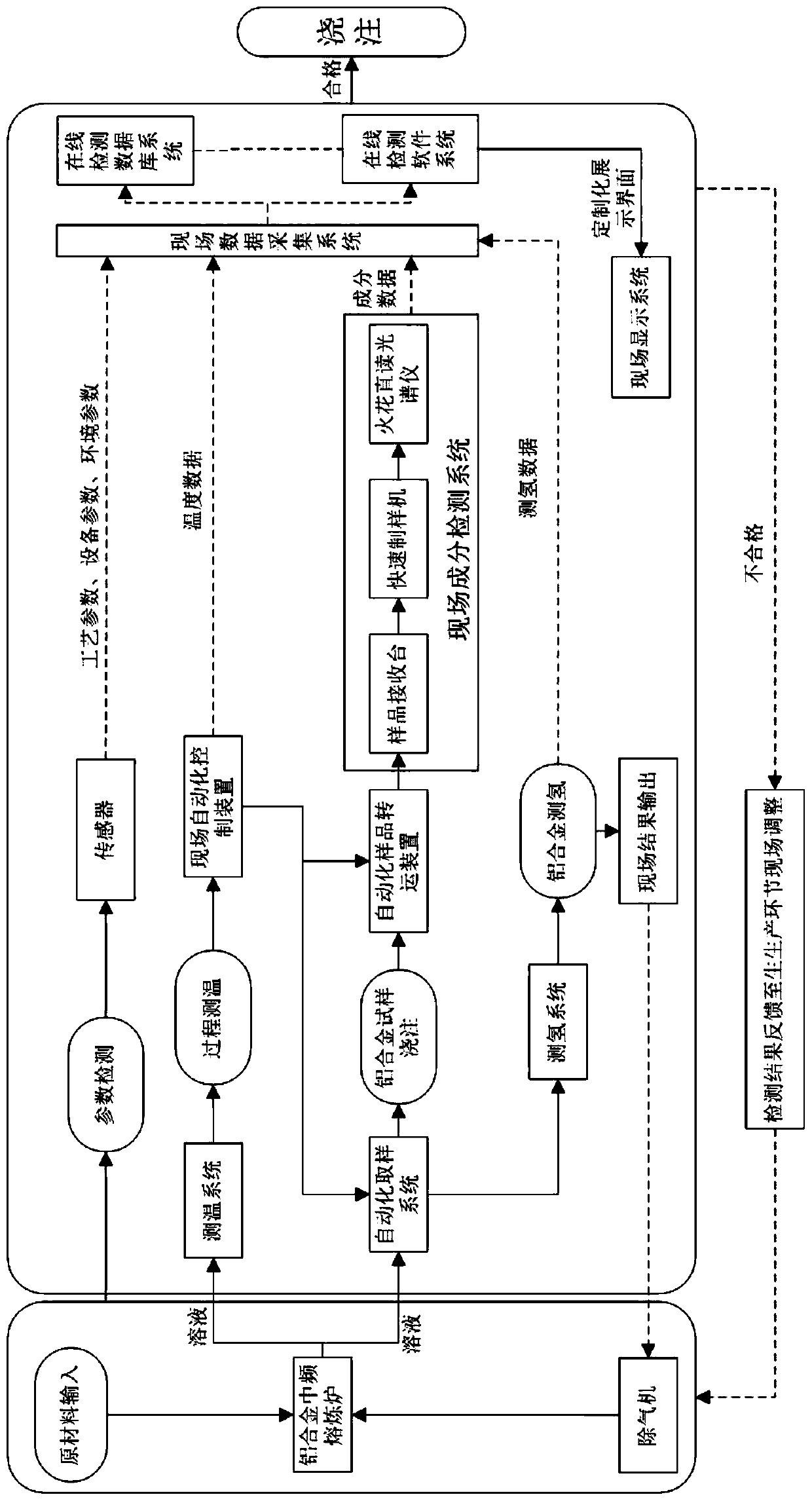

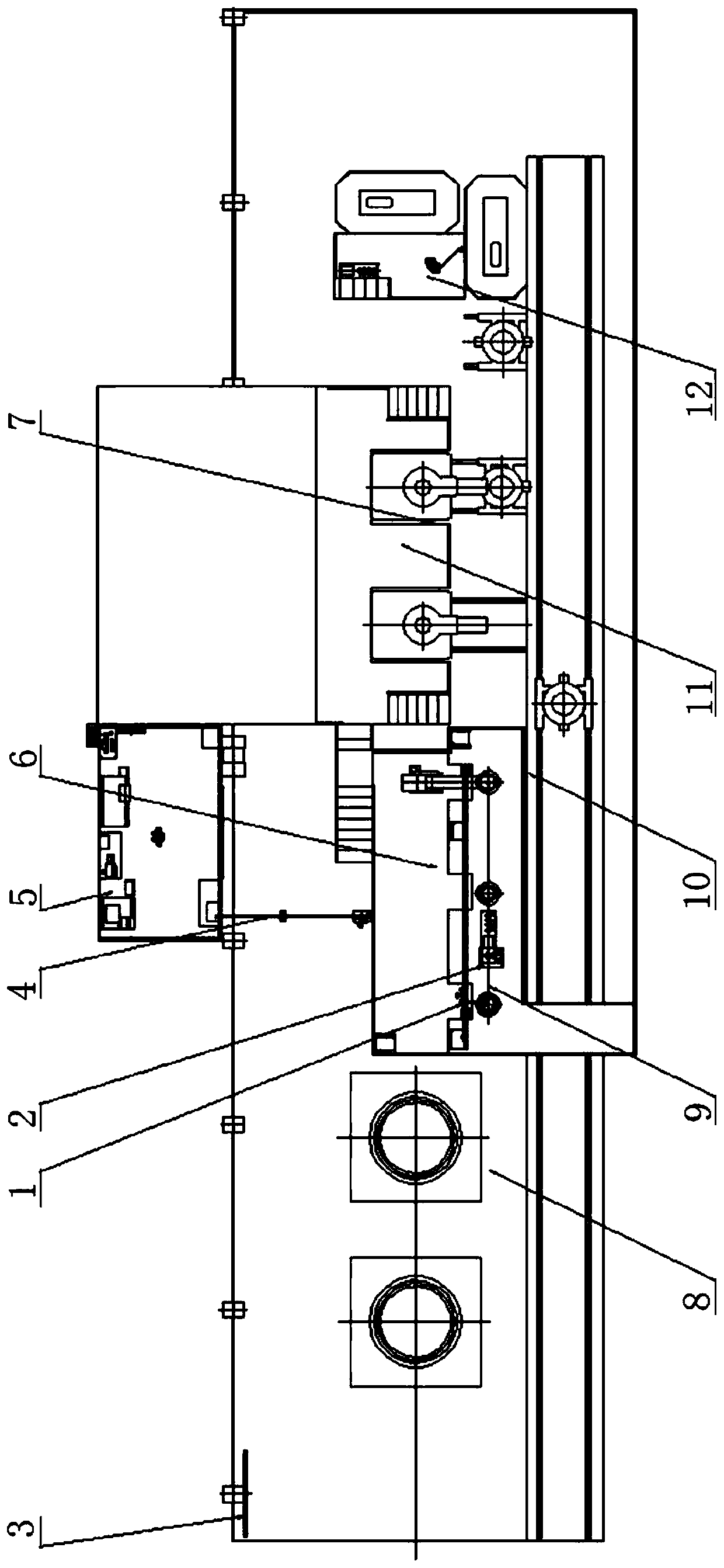

[0060] Such as Figure 1 to Figure 5 As shown, the method for online detection and data application of aluminum alloy casting and smelting process includes the following steps:

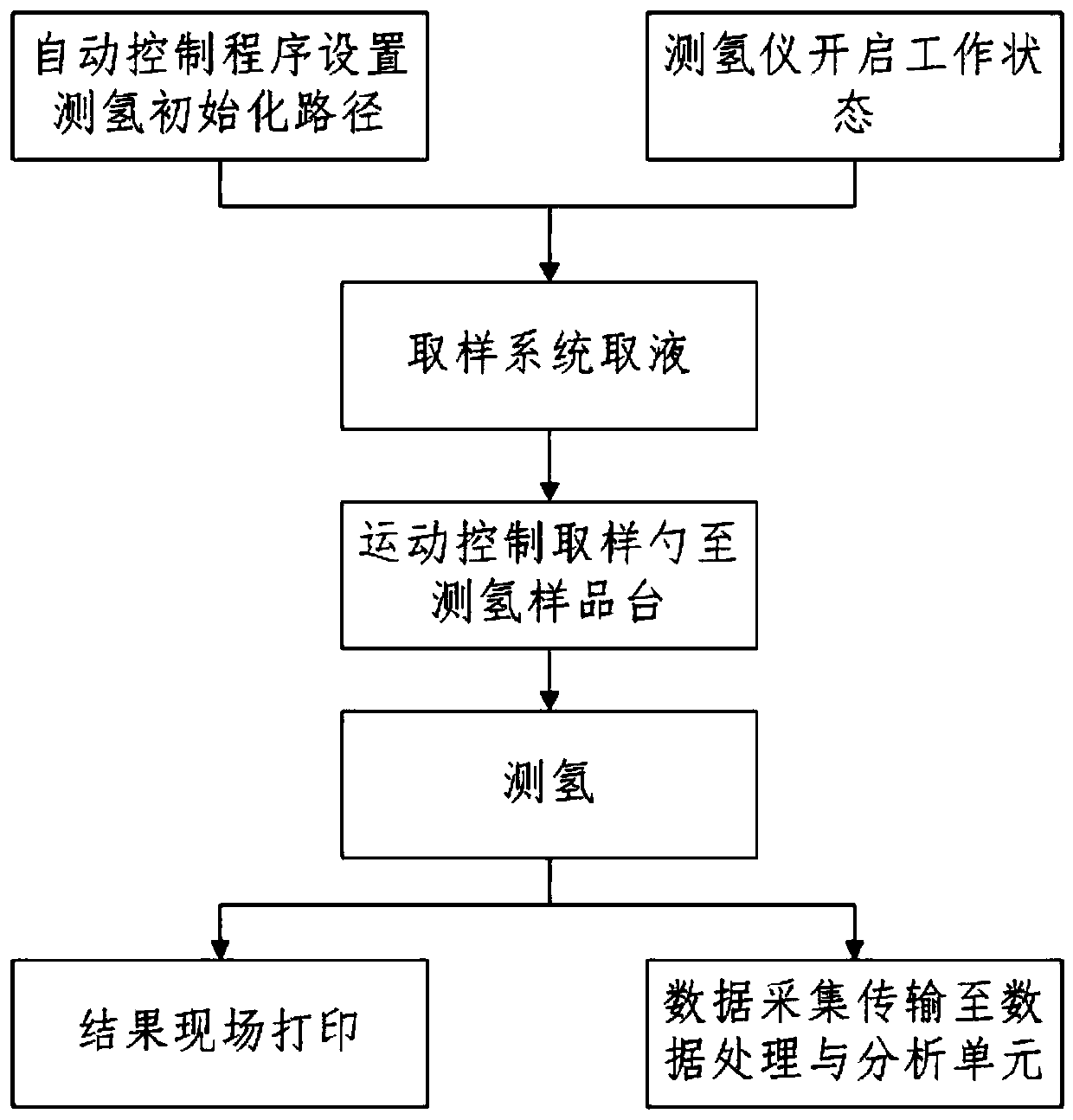

[0061] Step A, using the automated sampling system 1 to sample the melt formed after the aluminum alloy is smelted, and the automated sampling system 1 sends the melt sample to the hydrogen measuring system 2 and the pouring area 8;

[0062] Step B1, the hydrogen measuring system 2 measures the hydrogen content in the melt sample, and at the same time sends the hydrogen content measurement result to the on-site display system 3 for display, and decides whether to perform secondary degassing and refining according to the displayed hydrogen content measurement result ;

[0063] Step B2, the pouring area 8 completes pouring of the melt sample and obtains the pouring sample, the automatic sample transfer device 4 sends the pouring sample to the on-site composition detection system 5, and the on-site comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com