High-performance condensation heat exchange tube based on bionic structure

A heat exchange tube and high-performance technology, which is applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of limited space for enhancing condensing heat exchange and low condensing heat transfer coefficient, so as to facilitate the elimination, Low rolling resistance and the effect of increasing the condensation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is a further detailed description in conjunction with the drawings:

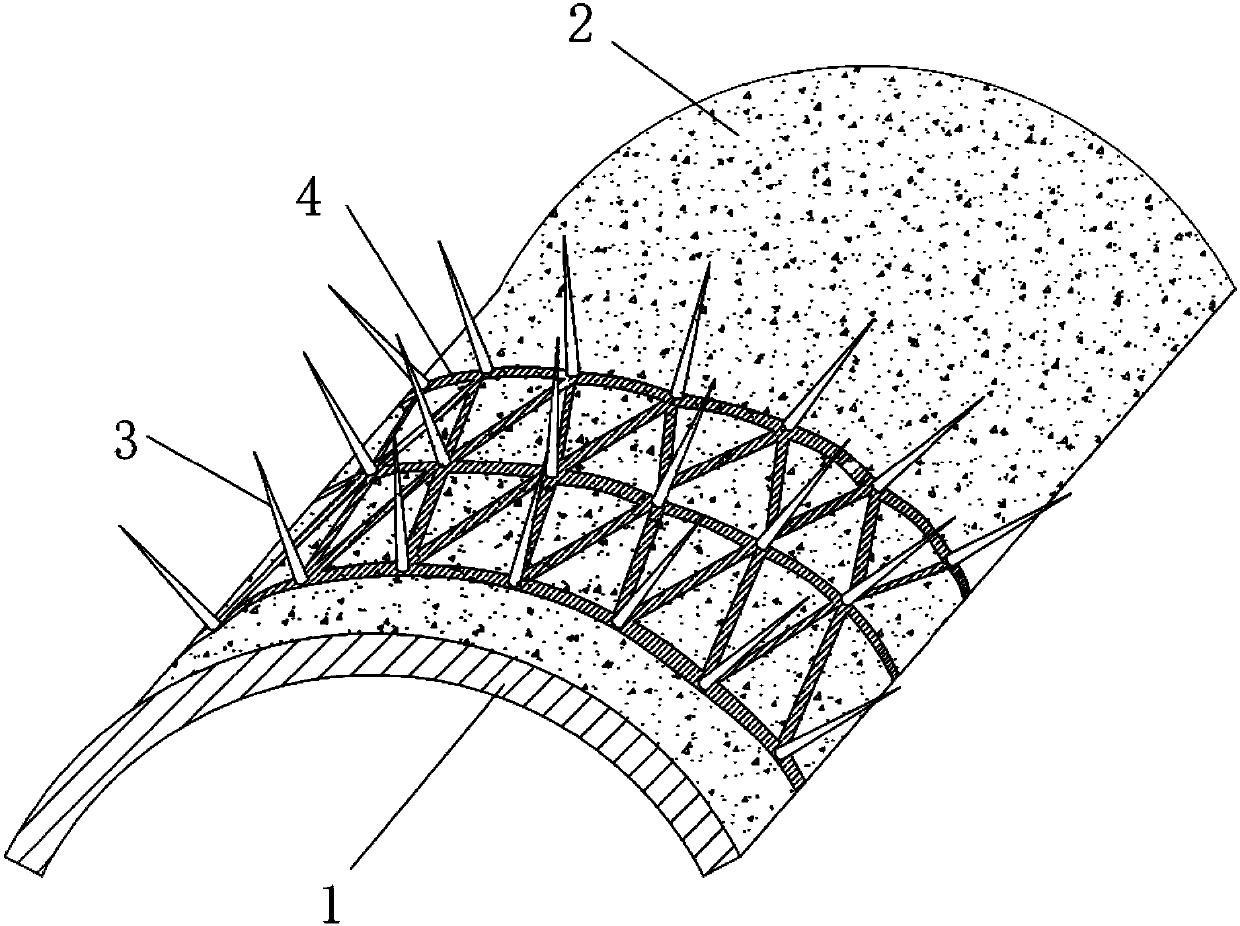

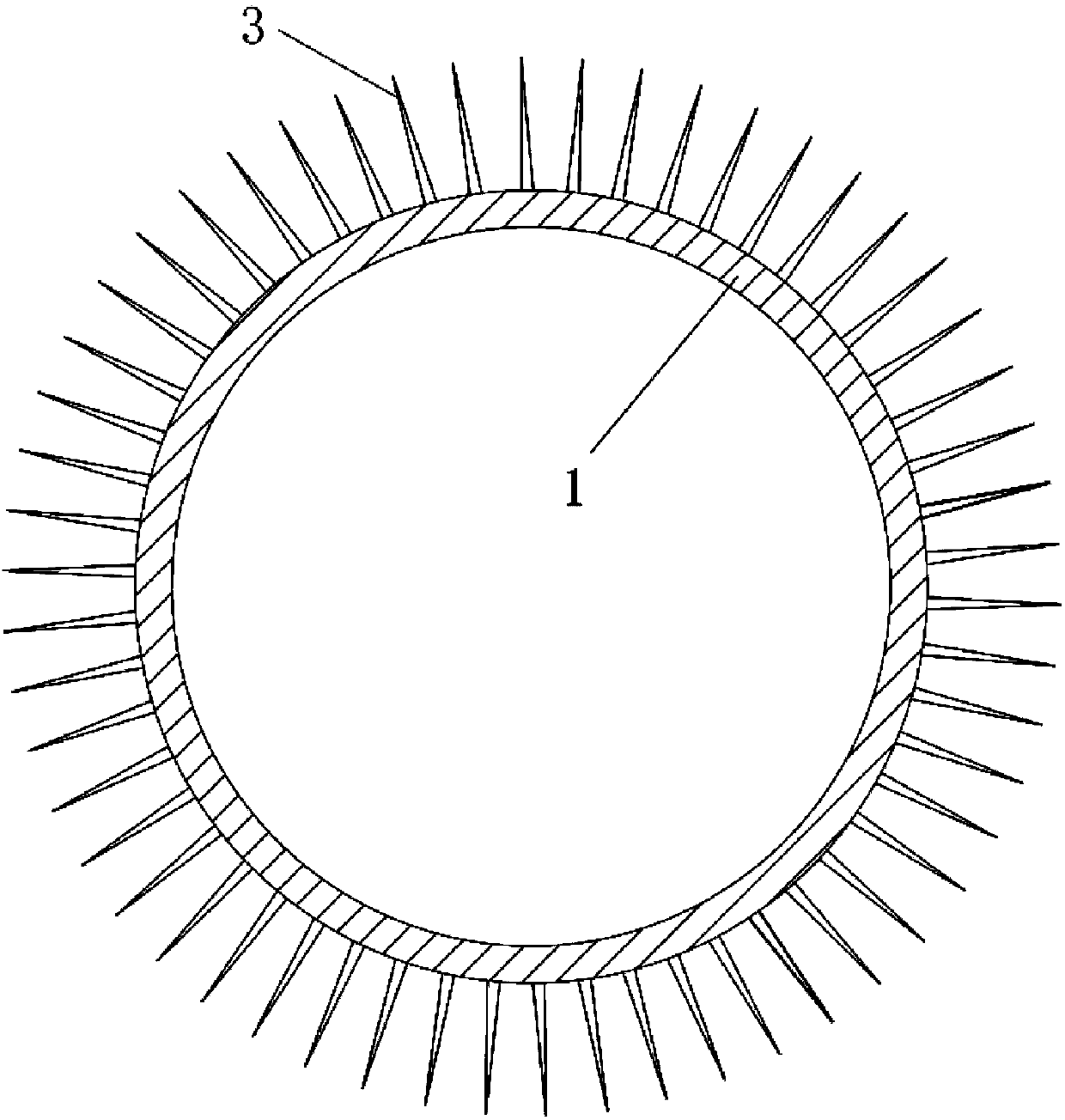

[0026] Such as figure 1 As shown, the present invention prepares a superhydrophobic substrate on the surface of a heat exchange tube base tube with hydrophobic microchannels and a needle-like hydrophilic bionic structure distributed on the superhydrophobic substrate. On the surface of the condensing heat exchange tube based on the bionic structure, the hydrophilic area and the superhydrophobic area are organically combined, and the needle-like hydrophilic bionic structure is distributed on the superhydrophobic substrate at equal intervals in a fork-row manner. The hydrophobic microchannel structure is reasonably distributed according to the arrangement of the needle-like hydrophilic bionic structure and the placement of the condenser.

[0027] In addition, the needle-like hydrophilic biomimetic structures can also be arranged on the superhydrophobic substrate in a random or in-line manner.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com