Visual inspection method for bottle packaging quality

A visual inspection and quality technology, applied in the direction of liquid/fluid solid measurement, measurement device, lubrication indicator device, etc., can solve the problems of long detection time, unsatisfactory, complex detection algorithm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

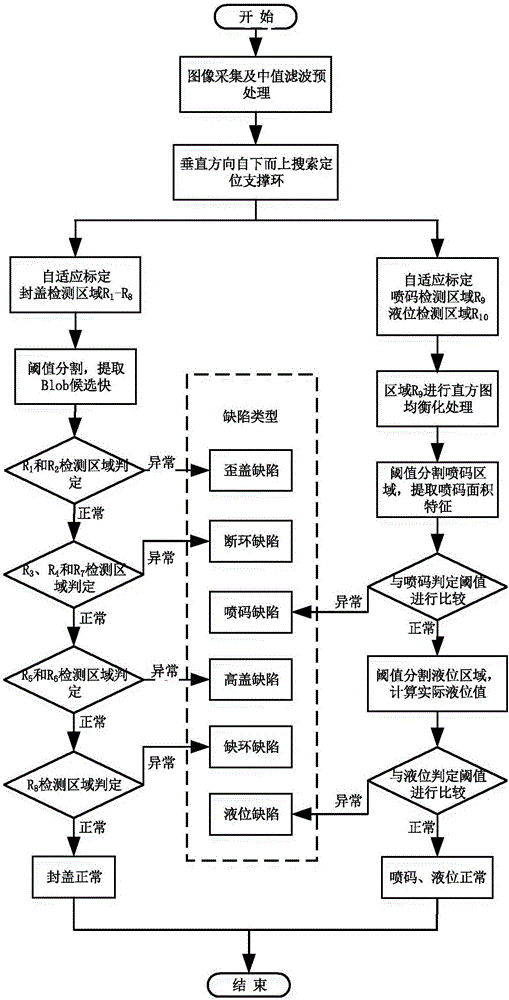

[0092] Such as Figure 1-6 , a kind of bottle packaging quality visual detection method, comprises the following steps:

[0093] Step 1: Obtain bottle image and preprocessing;

[0094] Step 2: Locate the support ring in the image;

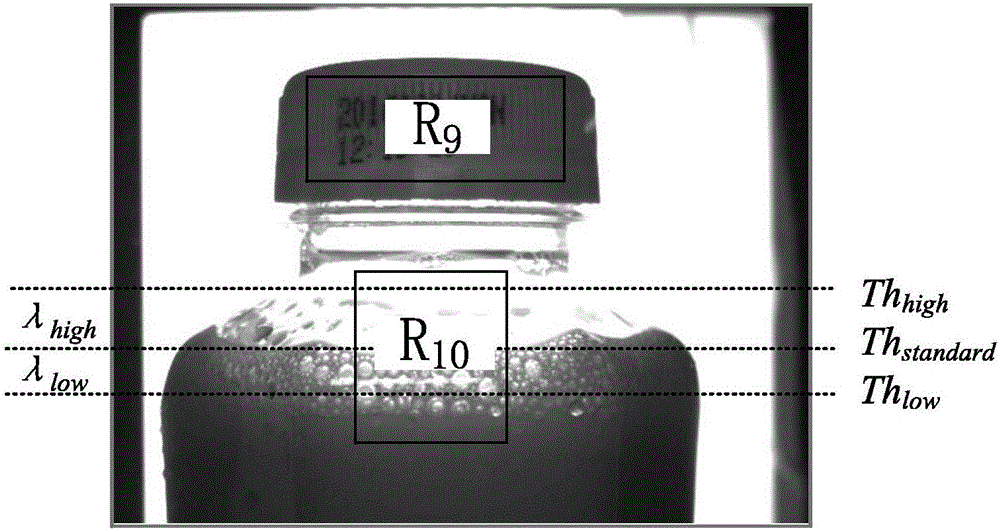

[0095] Step 3: Calibrate the cover, liquid level and inkjet detection area;

[0096] Step 4: Inspect closures, fluid levels, and coding for defects.

[0097] In step 1, through the backlight and RGB three-color strip light illumination, use the CCD industrial camera and image acquisition card to collect the image of the bottle body, and then send the collected image to the industrial computer for preprocessing, and use the median filter method to remove the image acquisition and Noise points that exist during transmission.

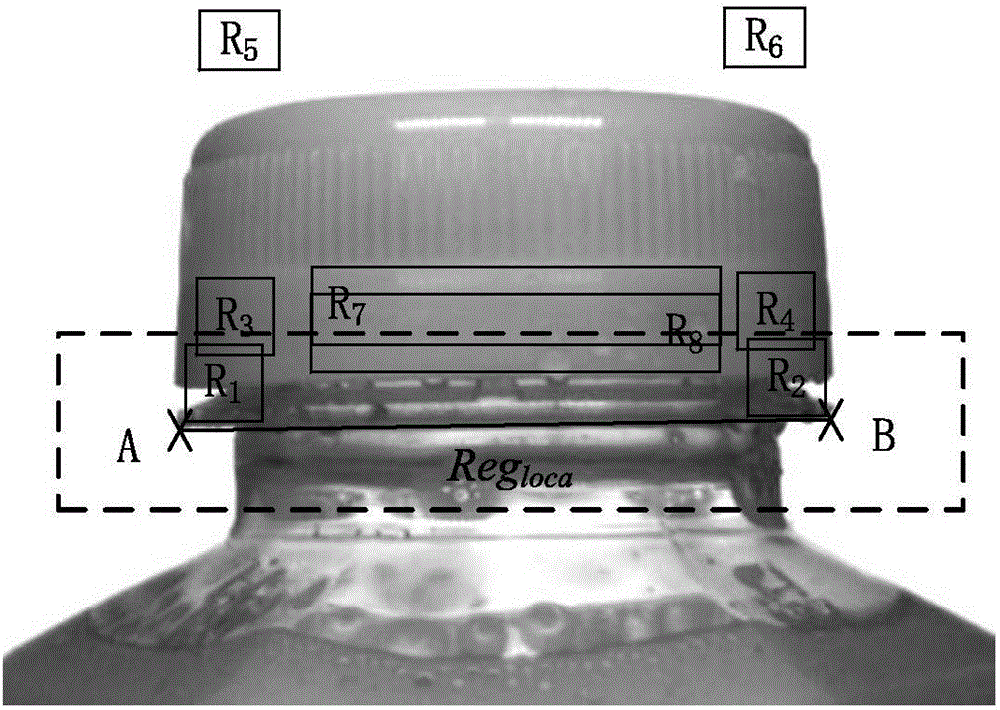

[0098] Step 2 comprises a coarse positioning step and a fine positioning step;

[0099] (1) Coarse positioning steps:

[0100] For the preprocessed image, select the positioning area Reg loca , the positioning area Reg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com