Method for deviation adjustment for detection of spatial position of steel belt roll system

A technology of spatial position and roll system, which is applied to the detection and adjustment of the spatial position of the steel belt roll system, and the field of position detection and deviation adjustment, which can solve the poor effect of the spatial position adjustment of the rolling system, the adjustment process is time-consuming and laborious, and the adjustment accuracy is low and other problems, to achieve the effect of high degree of detection automation, convenient detection and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

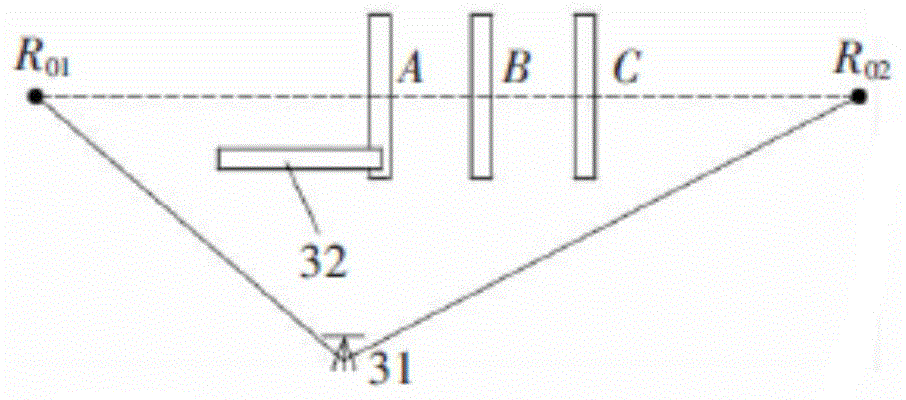

[0027] like figure 1 As shown, R 01 , R 02 The two datum center points for the roller shaft inspection, and the line connecting the two points is used as the datum reference line for the roller system inspection. Our purpose is to use the total station to measure the spatial positional relationship between the roller shafts A, B, C and the datum reference line—— Verticality / levelness, etc., and then adjust the position of its roller system.

[0028] The specific detection includes the following steps:

[0029] see figure 1 , set up the total station between two center points; total station 31, two reference points R 01 , R 02 Three points form a triangle;

[0030] see figure 1 , fix a tooling swing arm, that is, the bearing rod 31, on the measured stick axis A;

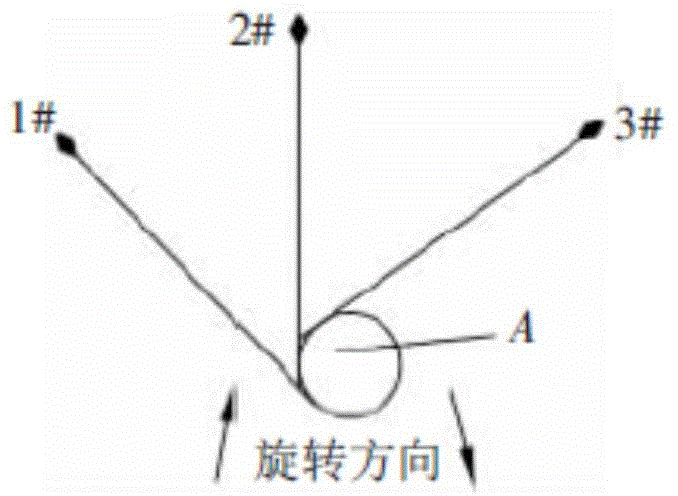

[0031] Detection of R by Total Station 01 , R 02 Coordinates, the coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com