Steel ball surface defect detection automatic sorting device

A defect detection and automatic sorting technology, applied in the field of defect detection, can solve problems such as the inability to guarantee the full expansion of the spherical surface, the inability to guarantee full expansion, and the addition of degaussing steps, so as to achieve a high degree of detection automation, accurate and efficient defect detection, and improved detection The effect of the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The steel ball surface defect detection and automatic sorting device of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

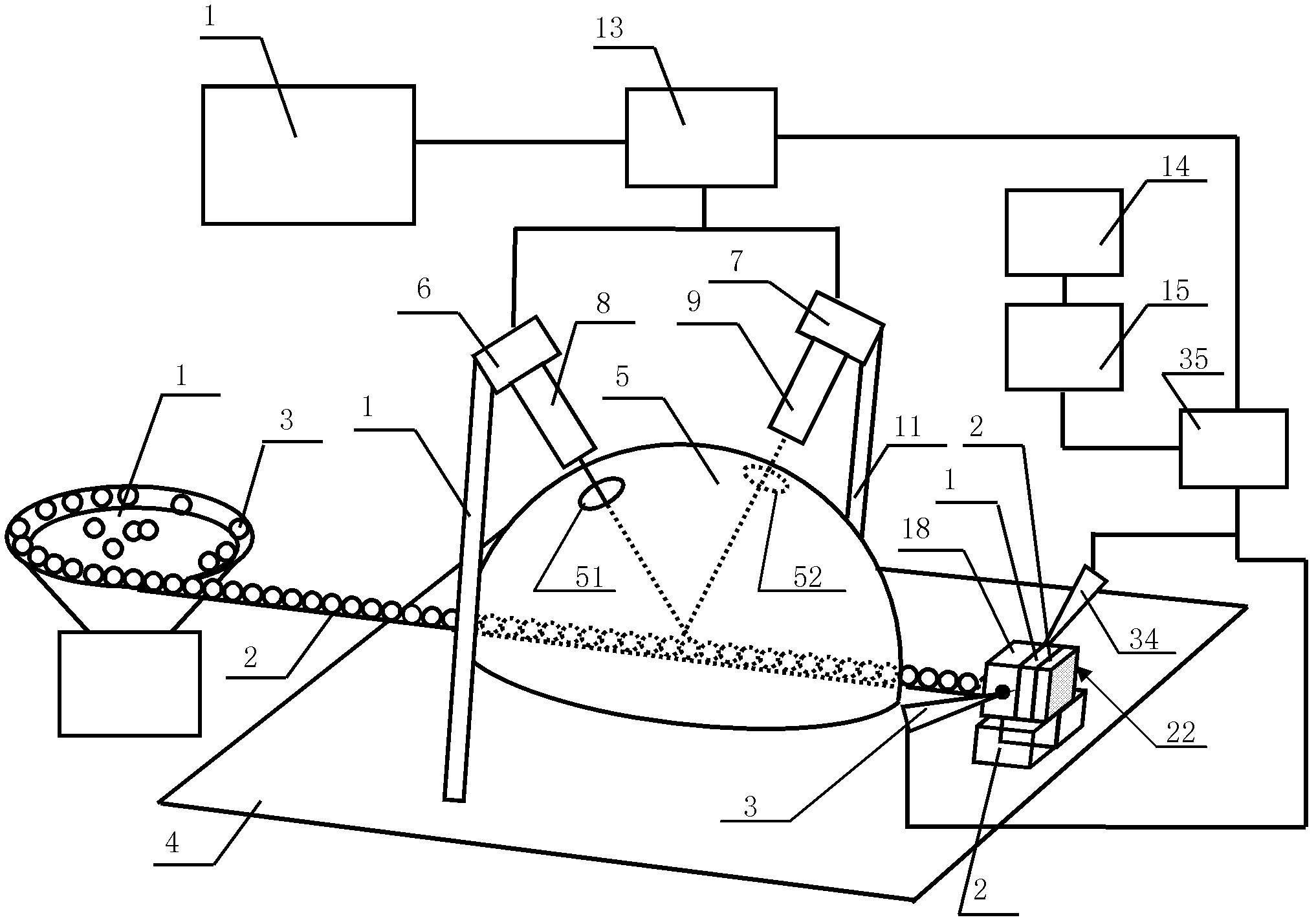

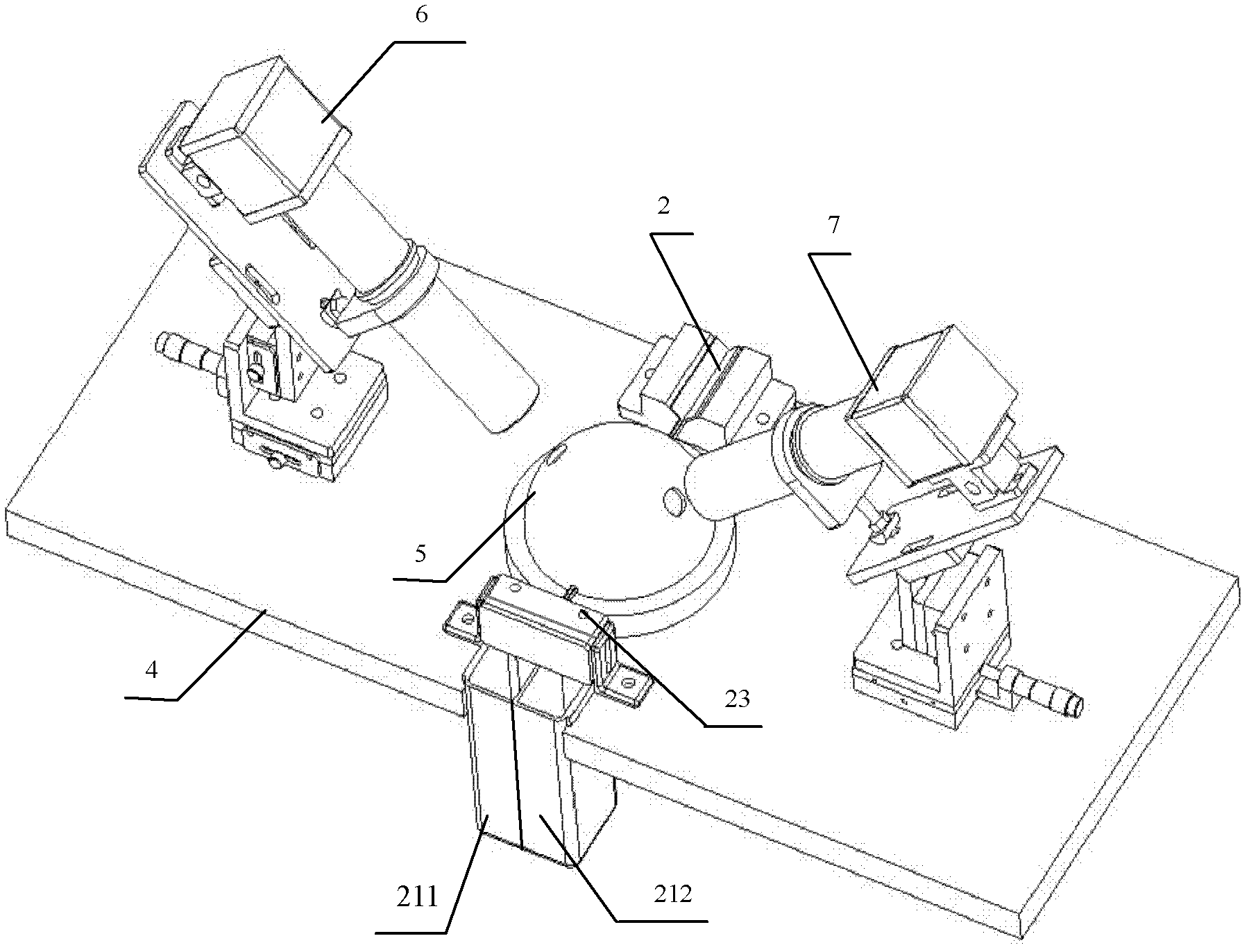

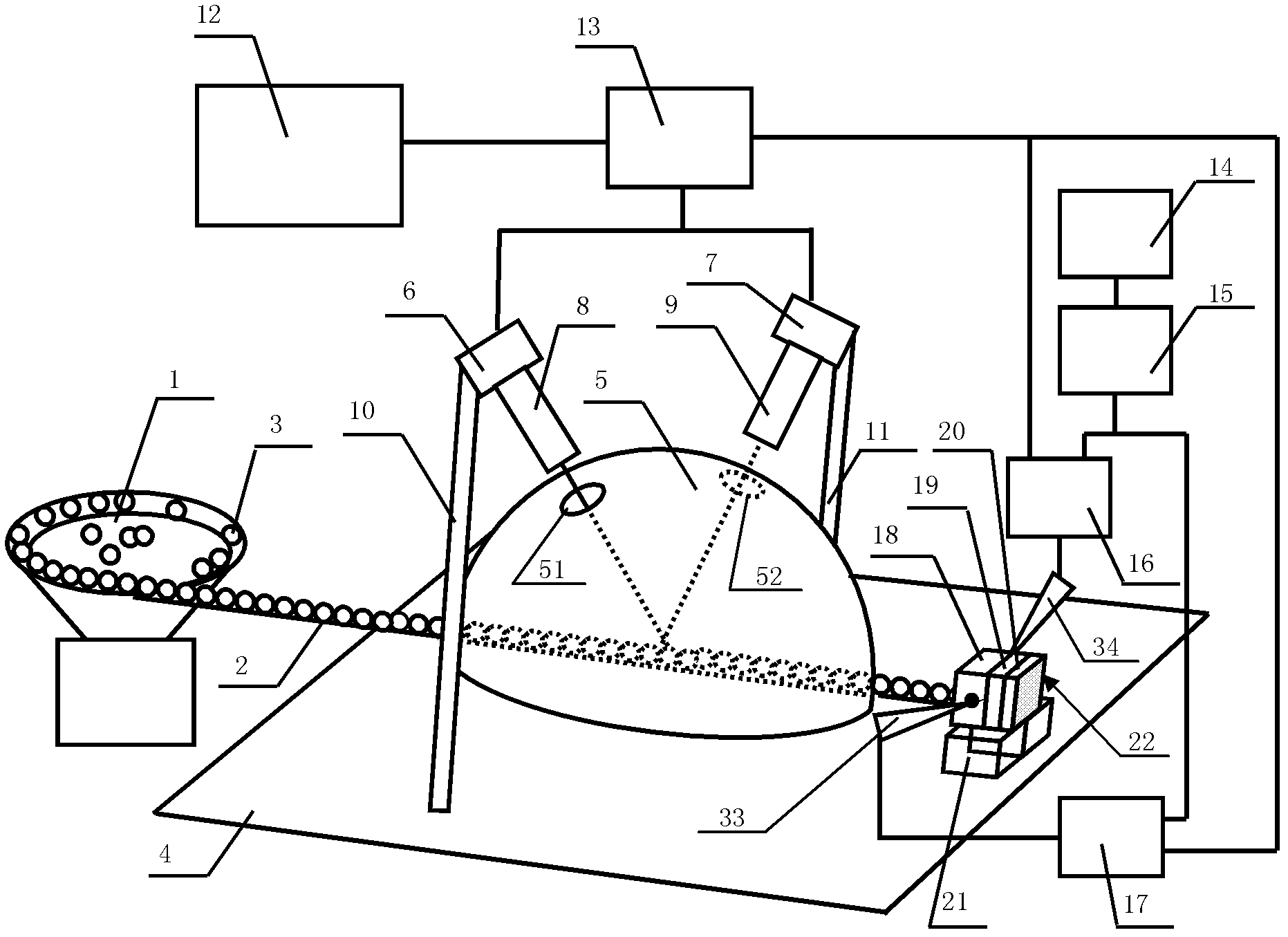

[0054] Such as figure 1 , figure 2 , image 3 As shown, the steel ball surface defect detection automatic sorting device of the present invention includes a workbench 4, and the workbench 4 is provided with a light source 5 composed of a light source bowl cover and an LED light source covered in the light source bowl cover. The light source described above adopts a diffuse reflection dome-shaped LED light source. The left and right sides of the light source bowl cover are symmetrically provided with a left bracket 10 and a right bracket 11, the left side camera 6 is installed on the left bracket 10, and the right side camera 6 having the same structure as the left side camera 6 is installed on the right bracket 11. The camera 7, the lens 8 of the left camera 6 and the lens 9 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com