Machine vision based on-line detection system and detection method thereof

A machine vision and detection system technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of high labor intensity and complex precision of manual detection, simple to complex detection items, low degree of automation, etc., and achieve a high degree of detection automation. , the detection effect is good, the detection efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

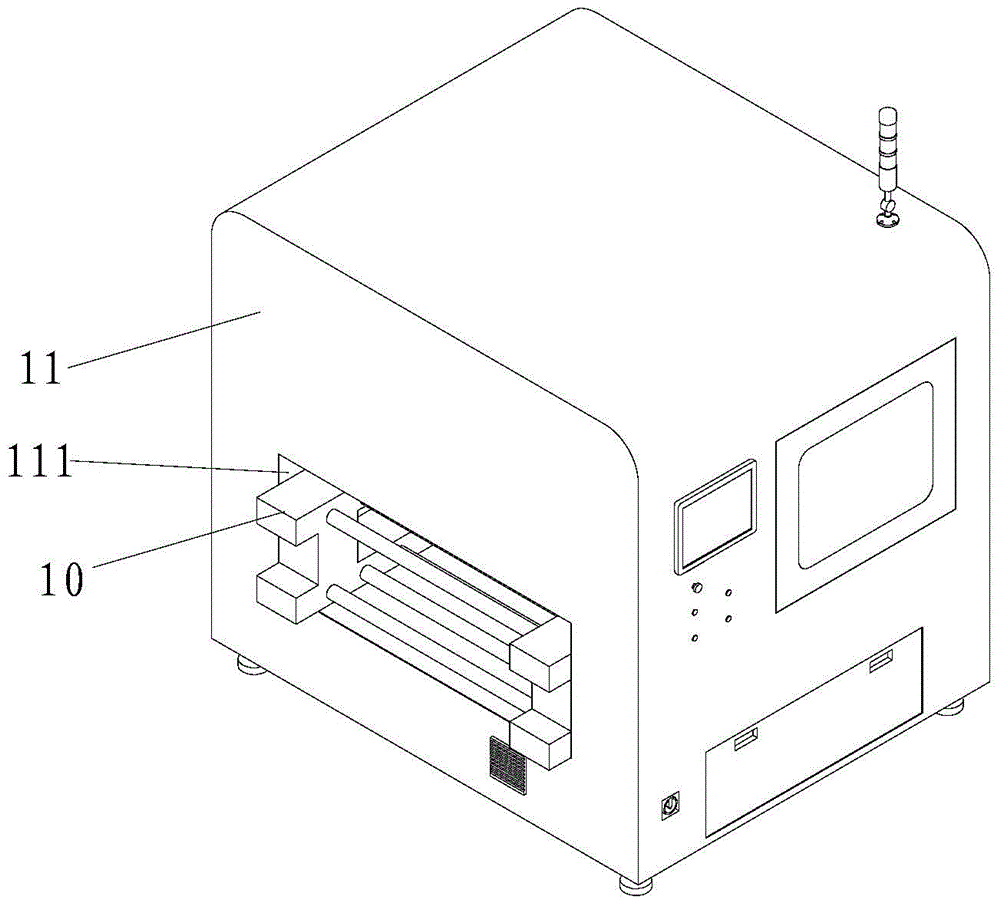

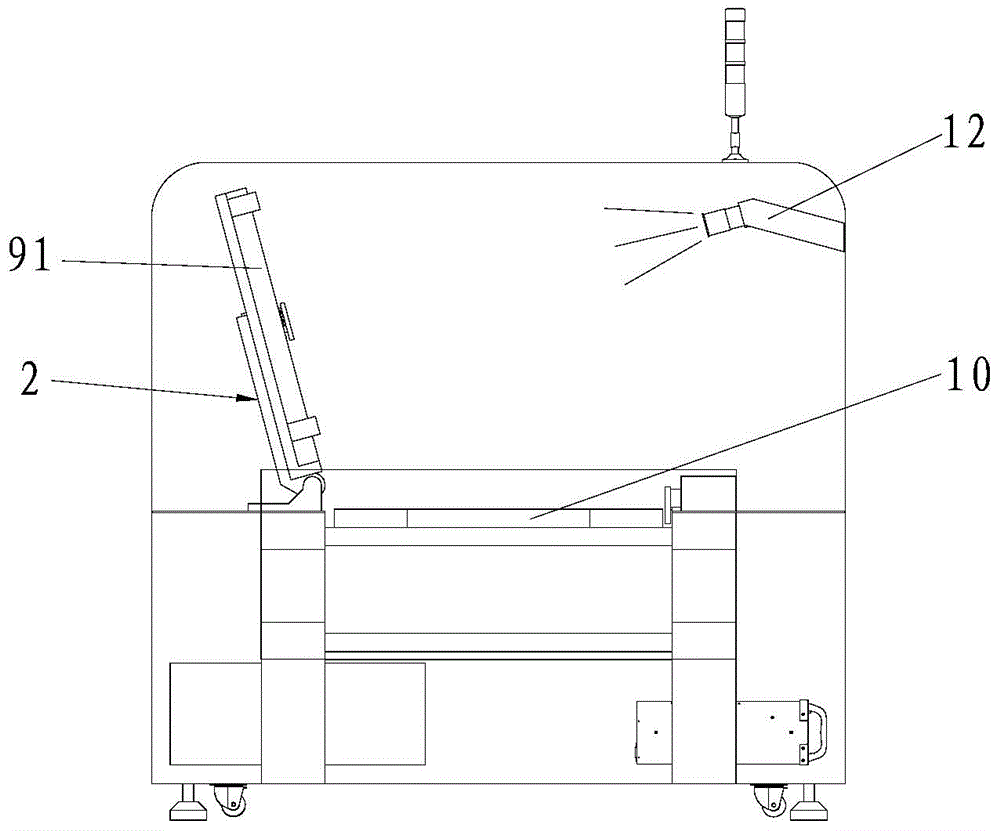

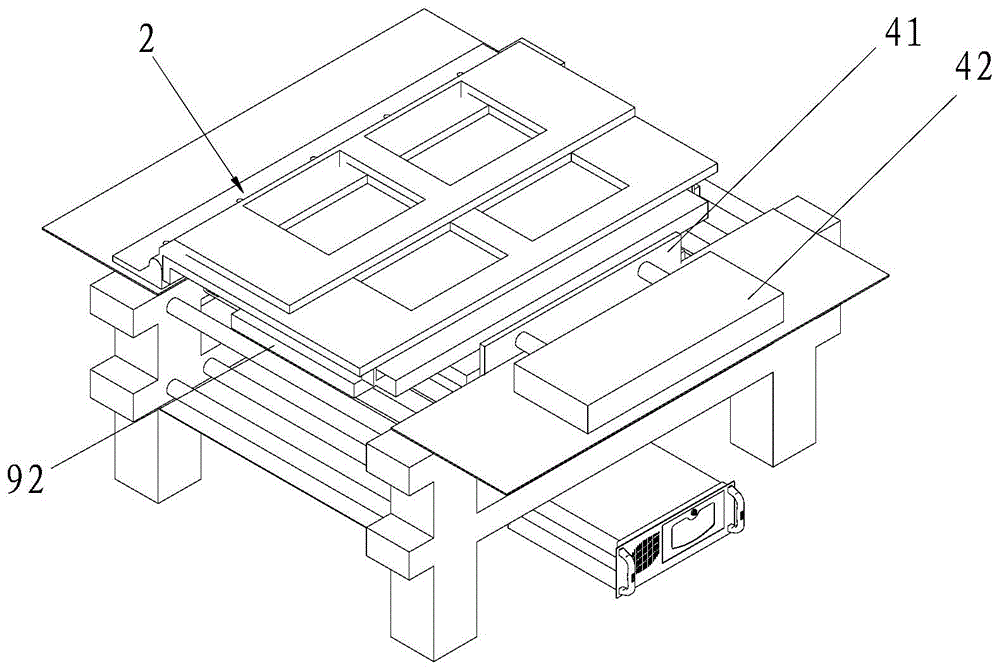

[0069] Such as Figure 1 to Figure 12As shown, as the first embodiment of the turning part 2 , the turning part 2 includes an upper mechanical arm 21a for turning over the display device 91 and a lower mechanical arm 22a for turning over the protective tooling 92 . First, the display device 91 and the protective tooling 92 are simultaneously turned over to an angle facing the imaging device 12 by the upper mechanical arm 21a and the lower mechanical arm 22a, and then the protective tooling 92 is turned over to the transmission line 10 by the lower mechanical arm 22a; After the imaging device 12 captures the image, the lower mechanical arm 22a turns over the protective tooling 92 to be attached to the display device 91, and then the display device 91 and the protective tooling 92 are simultaneously placed on the display device 91 and the protective tooling 92 through the upper mechanical arm 21a and the lower mechanical arm 22a Flip over to transfer line 10. The lower mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com