A mobile on-site X-ray pipeline rolling filming device

An X-ray and pipeline technology, which is applied in the field of on-site X-ray pipeline rolling filming devices, can solve the problems of low flaw detection efficiency and achieve the effects of conveniently identifying flaw detection locations, speeding up flaw detection progress, and improving flaw detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

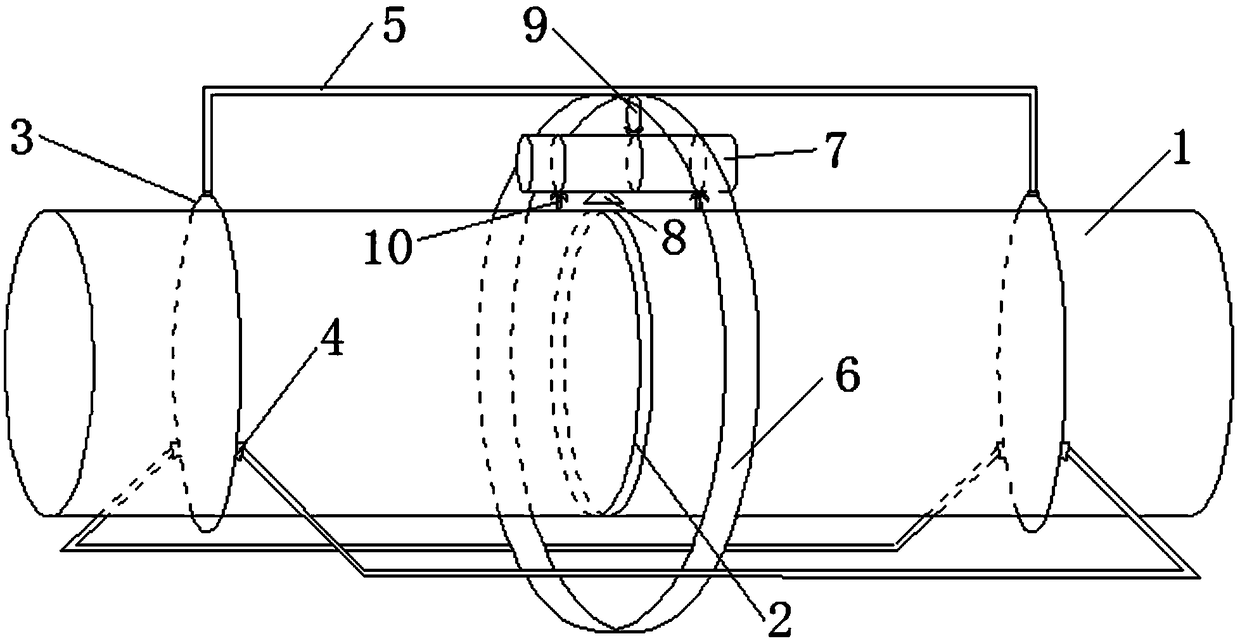

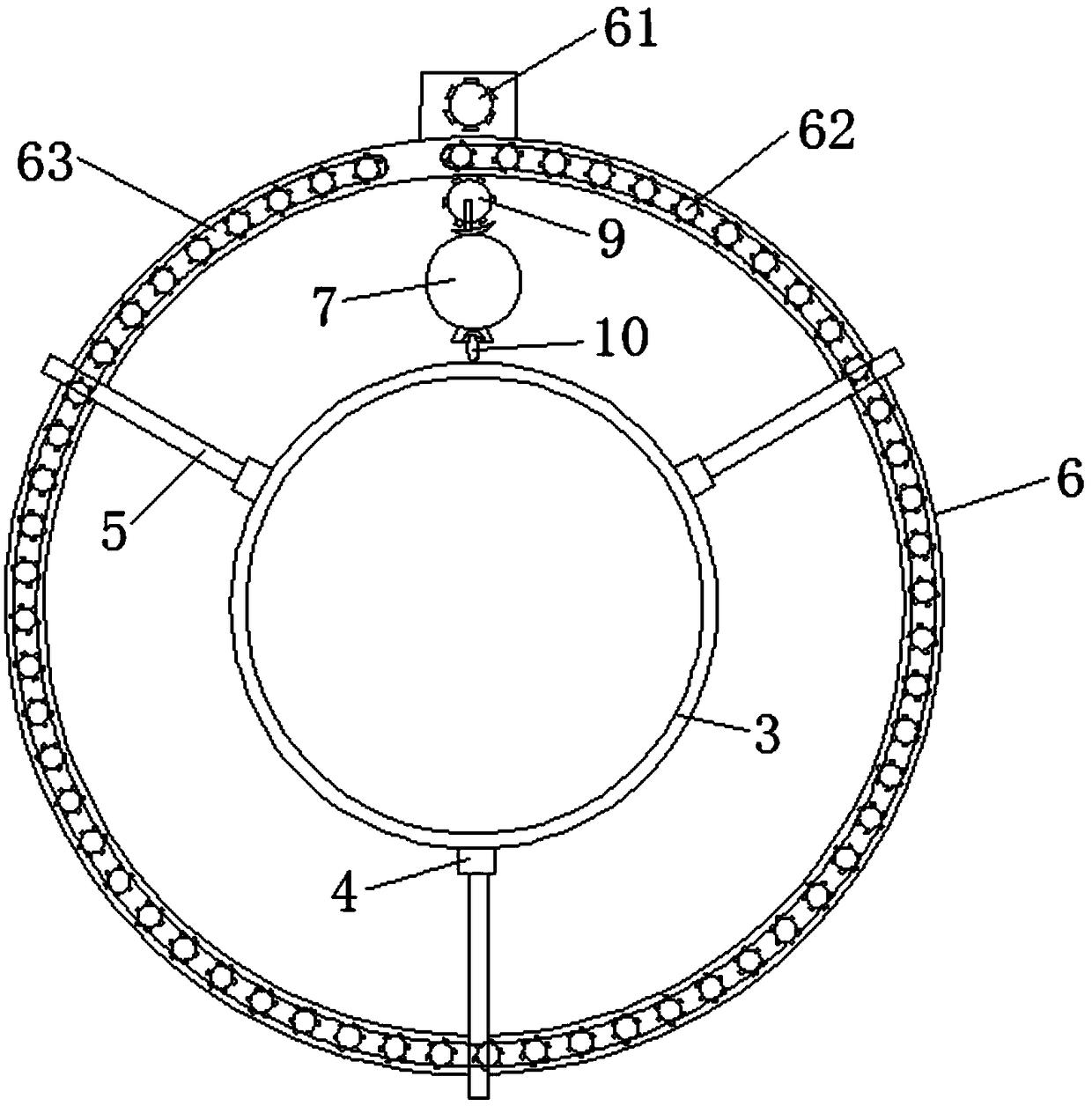

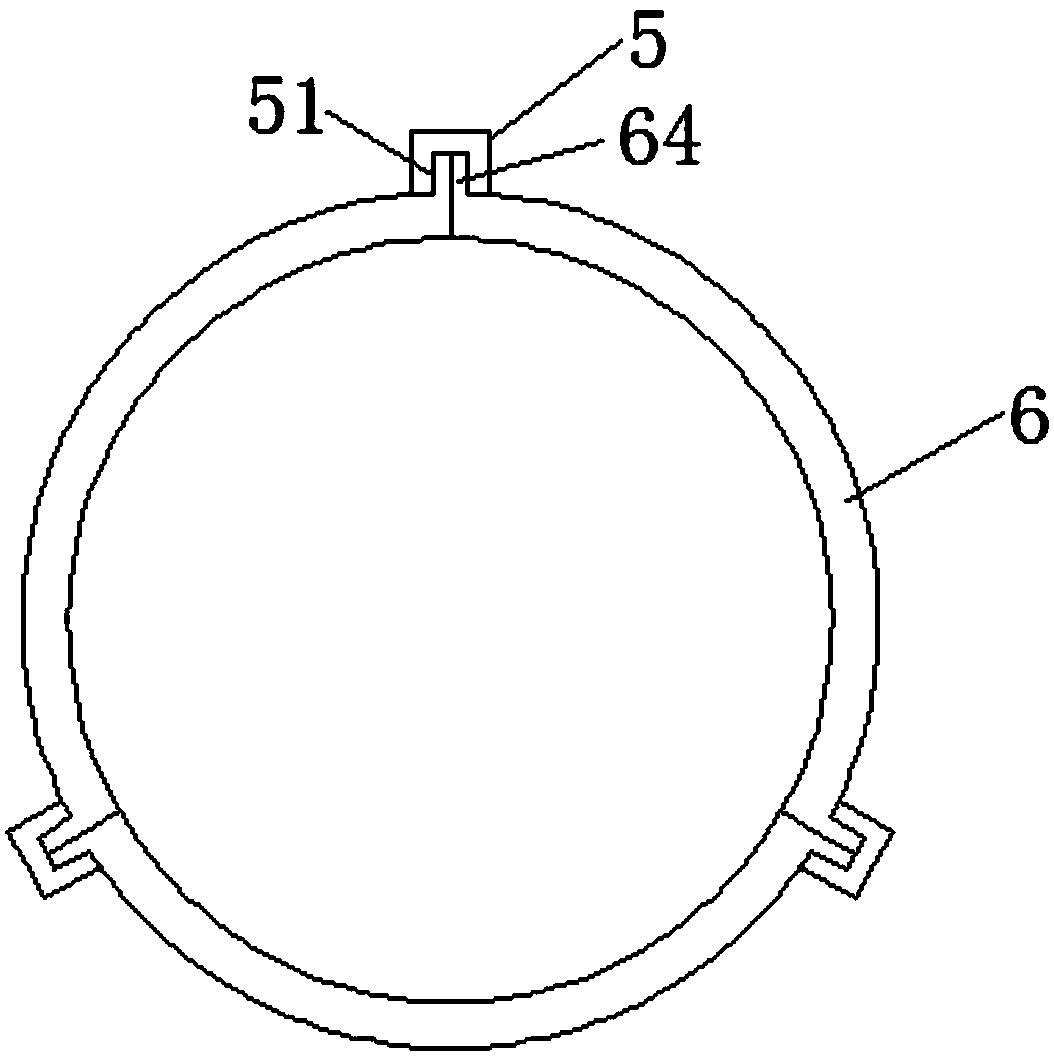

[0034] Such as figure 1 , figure 2 , image 3As shown, a mobile on-site X-ray pipeline rolling filming device of the present invention includes a support frame, a running mechanism and a walking mechanism. The support frame is installed on the outer surface of the pipeline 1 to be tested, and the running mechanism is installed on the On the support frame, the running mechanism is located between the running mechanism and the pipeline 1 to be tested. The support frame provides stable support for the whole device, especially to improve the support point for the track 6 in the running mechanism. The combination of the running mechanism and the running mechanism makes The X-ray machine 7 is free to circle around the outer surface of the pipeline 1 to be tested, which is convenient for the X-ray machine 7 to find the flaw detection position and improve the flaw detection efficiency; the support frame includes a fixed ring 3, a fixed connection end 4 and a connecting rod 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com