Continuous fiber-reinforced high-temperature ceramic fiber filter element and preparation method thereof

A high-temperature ceramic and fiber filtration technology, applied in the field of inorganic non-metallic materials and ceramic filter materials, can solve the problems of low filter element toughness and wear resistance, difficult product performance control, complicated preparation process, etc., to improve strength and rigidity. , Conducive to demoulding, increase the effect of pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

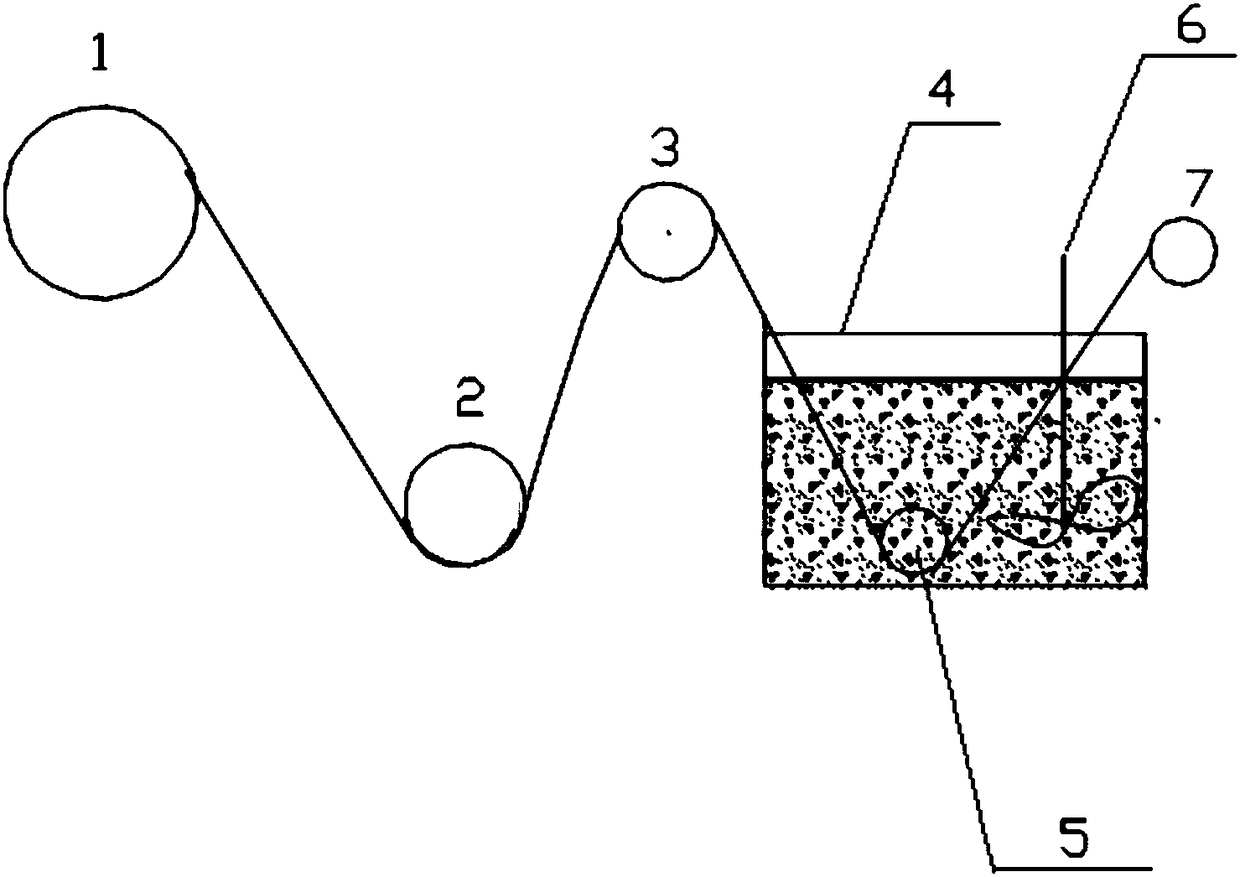

[0033] like figure 1 As shown, a preparation process of a continuous fiber-reinforced high-temperature ceramic fiber filter element is to add 2000 g of mechanically chopped aluminum silicate fibers below 5 mm into a mixer with 28 L of water, and stir at a high speed of 600 rpm for 2 hours. Obtain a uniformly dispersed fiber slurry with a fiber diameter of 5-7 microns and a length of 0.2-1 mm, then add 1000 g of cordierite aggregates of 80-100 microns, 1000 g of water glass with a modulus of 2.5-3, and 1000 g of cationic starch, and stir at 200 rpm After 2 hours, a short fiber slurry with a concentration of 15% was prepared.

[0034] The 320Tex twisted continuous high-silica fiber is tensioned by the rotating bracket 1, the tensioner 2 and the tensioner 3, and then passes through the directional roller 5 in the slurry tank 4 equipped with short fiber slurry, and the short fiber slurry passes through the agitator 6. After uniform stirring, the continuous fiber passes through th...

Embodiment 2

[0038] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0039] Add 4000g of chopped mullite fibers below 5mm into a mixer with 50L of water, and stir at a high speed of 600rpm for 1 hour to obtain short fibers with a diameter of 3-5 microns and a length of 0.2-0.5mm, which are uniformly dispersed. Fiber slurry, then add 80-100 micron cordierite aggregate 2000g, concentration 12% aluminum sol 10L, cationic starch 2000g, stir at 200rpm for 1-2 hours to prepare short fiber slurry with a concentration of 13%.

[0040] Using 480Tex untwisted continuous high-silica fiber, after controlling the winding tension, carry out continuous winding on the vacuum mold in the direction of 45°, the winding step spacing is 2mm, and the vacuum degree of the mold is 0.06MPa. During the winding process, the ratio of continuous fiber to short wire is 1:2. After the wi...

Embodiment 3

[0043] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0044] Add 4000g of chopped alumina fibers below 5mm into a mixer with 40L of water, and stir at a high speed of 600rpm for 1 hour to obtain short fibers with a diameter of 5-7 microns and a length of 0.1-0.45mm, which are uniformly dispersed Then add 4000g of 80-100 micron alumina aggregate, 1600g of phosphate, and 800g of carboxymethyl cellulose, and stir at 200rpm for 1-2 hours to prepare short fiber slurry with a concentration of 20%.

[0045] Using 500Tex untwisted continuous alumina fiber, after controlling the winding tension, carry out continuous winding on the vacuum mold in the direction of 45°, the winding step spacing is 2mm, and the vacuum degree of the mold is 0.04-0.05MPa. During the winding process, the ratio of continuous fiber to short wire is 1:1. After the winding thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com