Motor integrated structure of hybrid electric vehicle

A hybrid vehicle, motor-driven technology, applied in hybrid vehicles, motor vehicles, power units, etc., can solve the problems of unreliable power connection, insufficient powertrain installation space, unstable operation, etc. The effect of small size and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

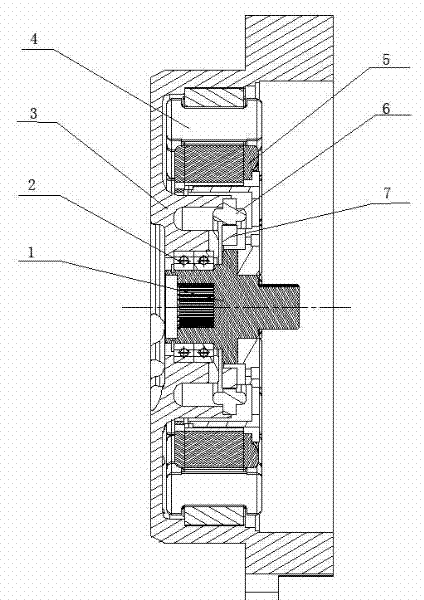

[0015] Such as figure 1 As shown, the motor integrated structure includes a motor drive shaft 1, two bearings 2, an integrated housing 3, a motor stator assembly 4, a motor rotor assembly 5, a motor resolver stator 6, a motor resolver rotor 7, and a resolver rotor Boss 31 etc. are installed.

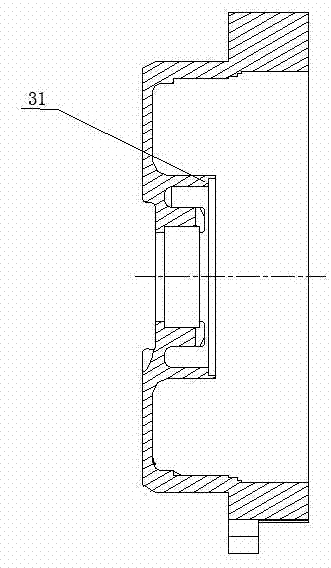

[0016] see image 3 , the integrated housing 3 is bowl-shaped, and there is a motor drive shaft installation hole in the center of the bottom. The double-row bearing 2 is assembled into the motor drive shaft installation hole by shrinking or cold pressing. in.

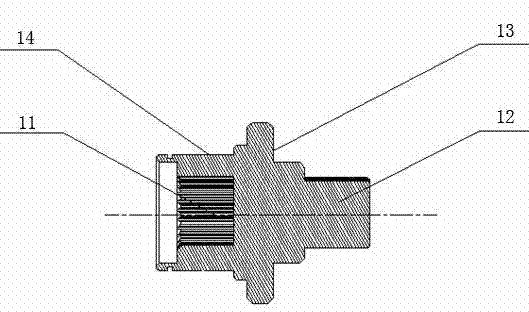

[0017] see figure 2 with Figure 4 , One end of the motor rotor shaft 1 is processed into an inner spline 11, and the other end is processed into an outer spline 12, and the power is transmitted to the engine and the transmission through the spline connection respectively. The middle part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com