Polygonal counter flow cooling tower

A cooling tower and counter-flow technology, which is applied in the field of cooling towers, can solve the problems of large air outlet resistance coefficient, large power consumption, and unsightly appearance, and achieve the effects of improving thermal performance efficiency, enhancing stability, and good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

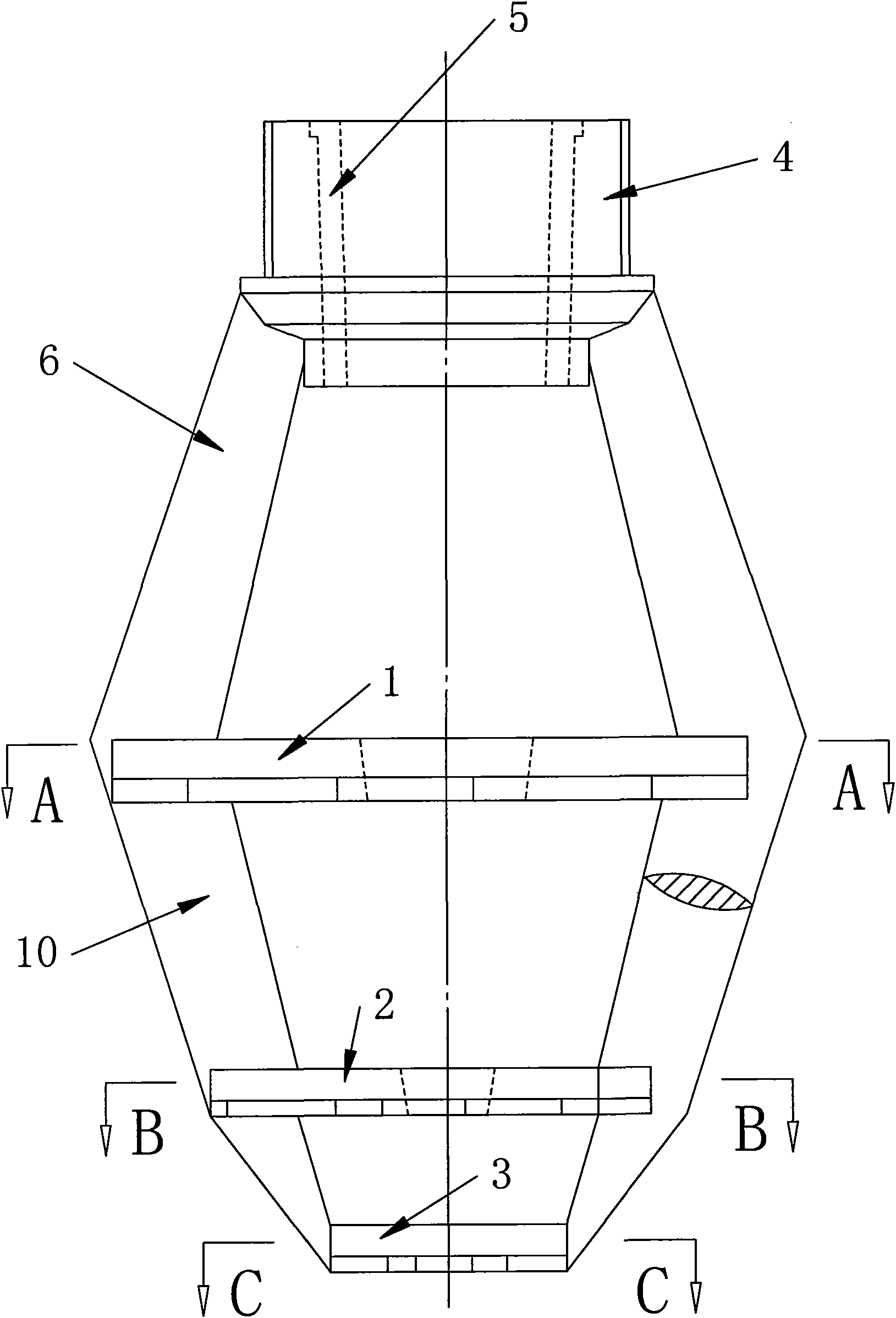

[0048] see Figure 11 , 12 The polygonal counter-flow cooling tower shown has a frame 11 whose periphery is a regular octagon. A frame 27 is arranged on the top of the frame, and an air duct 12 is arranged on the frame 27 . see Figure 21 , the air duct has a diffusion section 121, a working section 122, and an air inlet section 123 from top to bottom. . The foundation pier 20 supports the frame 11, and the motor 21 is connected with the fan through the shaft of the transmission mechanism. A ladder 28 is provided outside the frame.

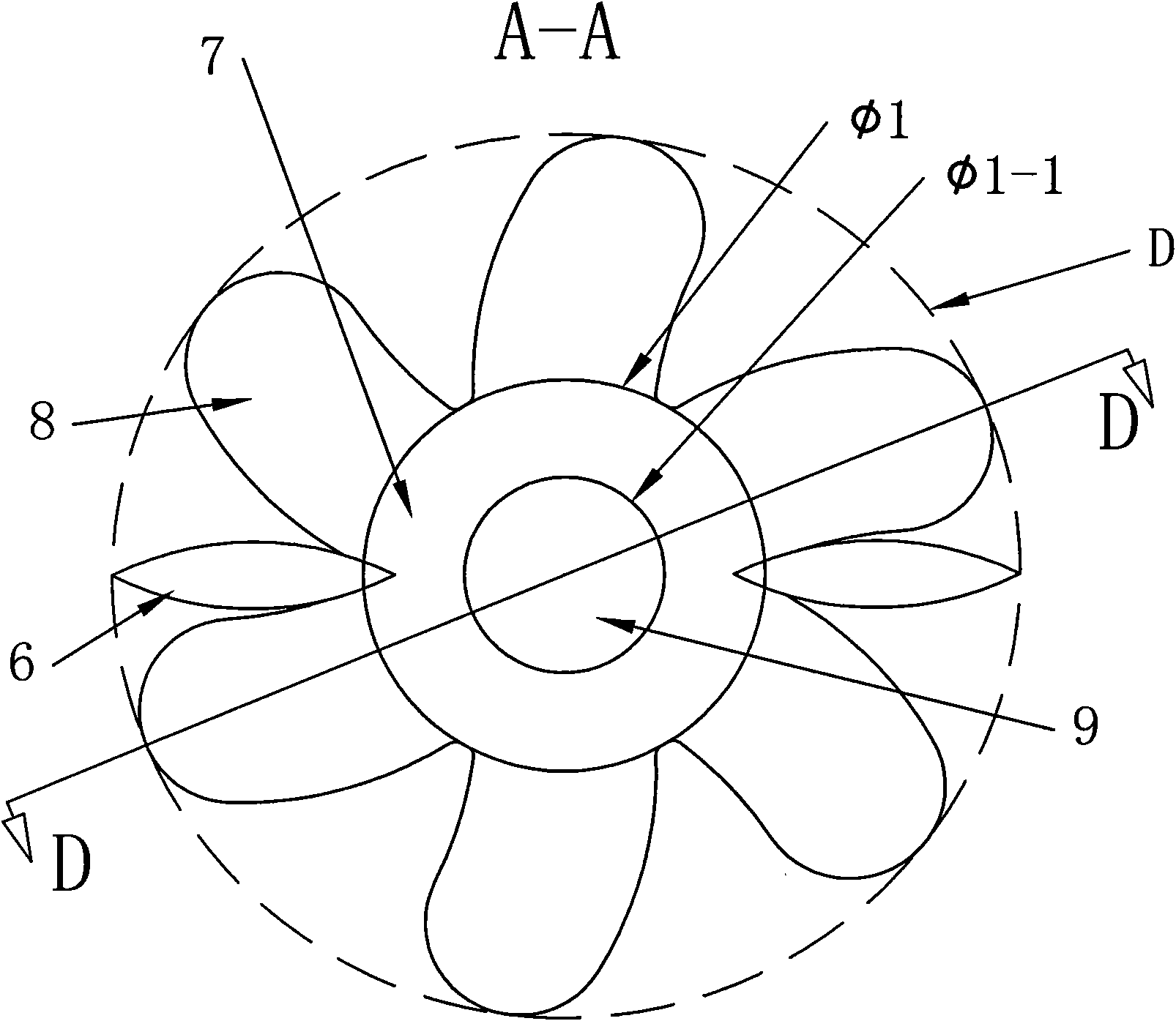

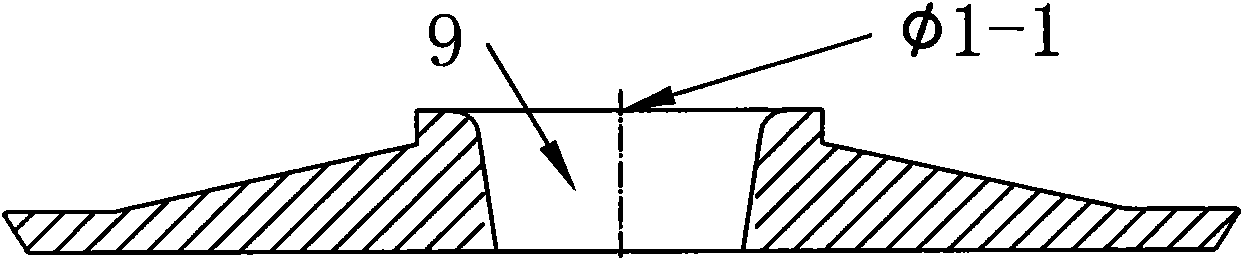

[0049] The upper periphery of the frame has wall panels 14 , and the lower periphery of the frame has air inlet windows 30 . The frame inside the wallboard is provided with a water-drinking filler 15 composed of a plurality of spaced filler sheets. The water shower filler 15 is placed on the filler bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com