Rotary flow guide type air draft system of laser cutting machine

A laser cutting machine and ventilation system technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large ventilation resistance, high noise, and high energy consumption, and achieve low ventilation resistance, low noise, and high energy consumption. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

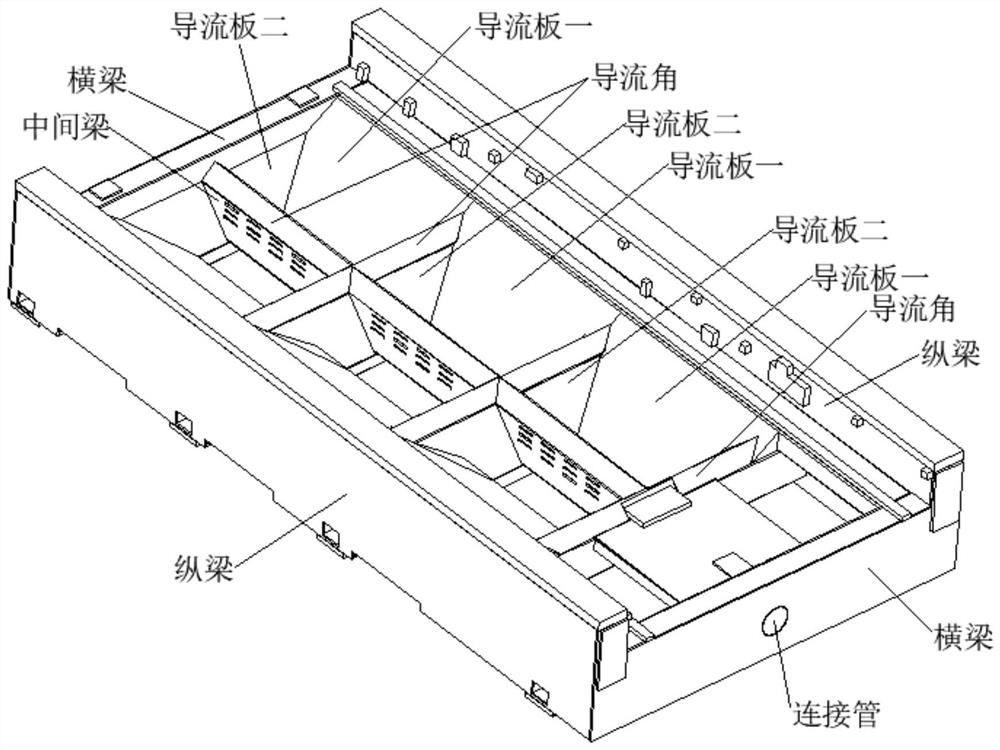

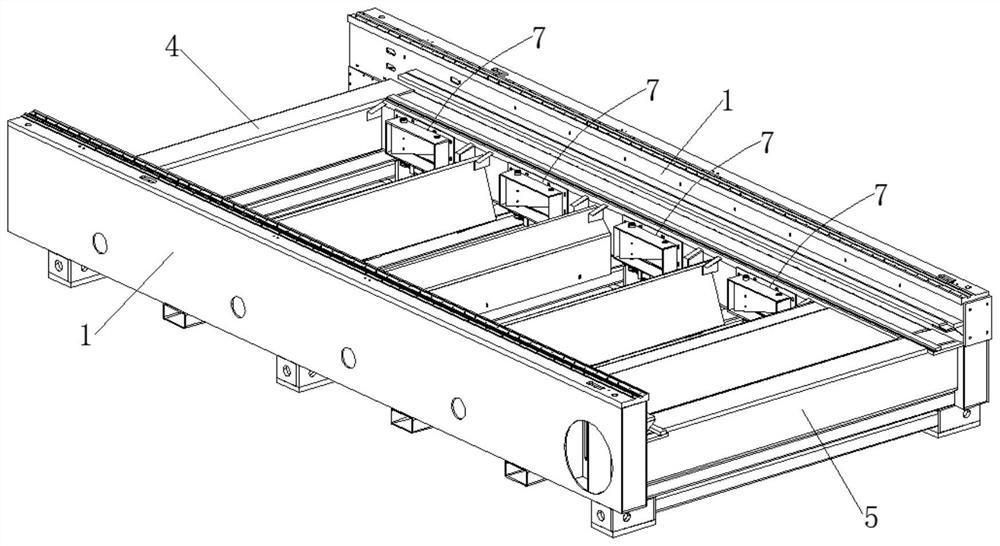

[0040] In the laser cutting machine rotary diversion type exhaust system, the left air guide pipe 2 is welded to the left longitudinal beam 1, the right air guide pipe 3 is welded to the right longitudinal beam 1, and the cross brace 4 The two ends are respectively welded to one end of the two longitudinal beams 1, and the two ends of the cross brace 5 are respectively welded to the other end of the two longitudinal beams 1, and communicated with the air outlet 10 on the longitudinal beam 1, and the left air guide pipe 2 The end of the right air guide pipe 3 is welded to the first 4 of the cross brace, and connected to the second 5 of the cross brace 5, and the exhaust operation is performed through the double exhaust air duct formed by the left air guide 2 and the right air guide 3, and the exhaust efficiency is improved. High, good cooling effect.

Embodiment 2

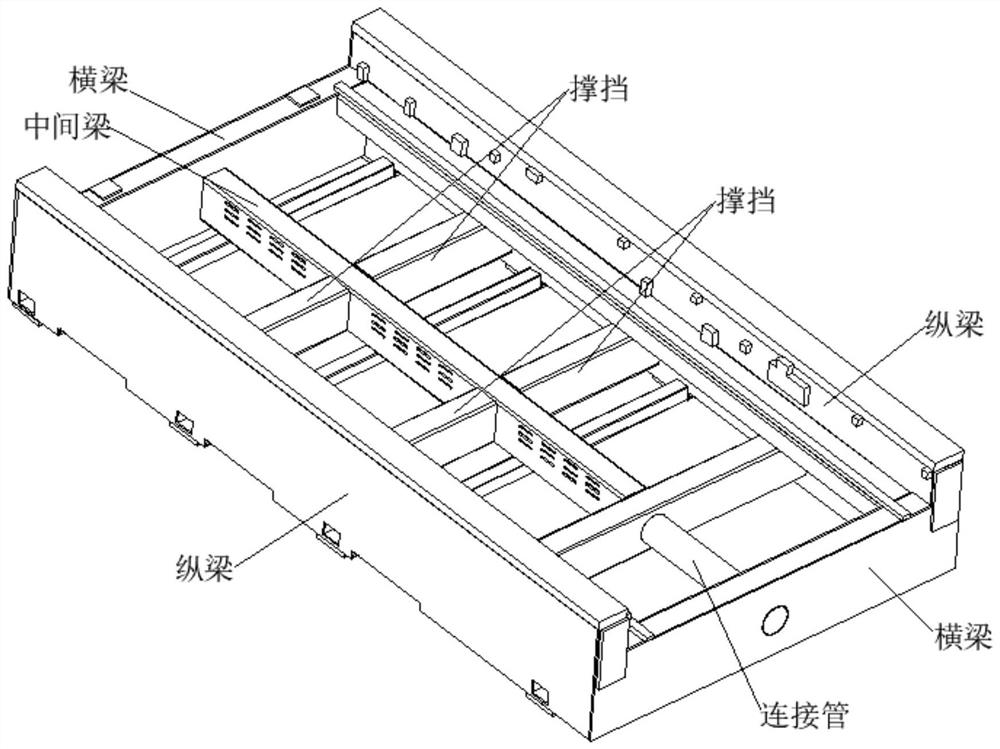

[0042] On the basis of Embodiment 1, a plurality of heat dissipation holes 2-1 are evenly spaced on the inner wall of the left air duct 2 and the right air duct 3, and the laser cutting machine is divided into multiple sections. During the cutting process, which section the light beam cuts to, the piston rod of the cylinder 72 in the rotary opening and closing mechanism 7 of this section shrinks, the connecting rod 73 rotates with the main shaft 74, and the main shaft 74 rotates with the sealing plate 75 to open, so that the outer The frame 70-2, the rectangular hole 70-1, and the heat dissipation hole 2-1 conduct, the piston rod of the other section cylinder 72 is in the extended state, the outer frame 70-2, the rectangular hole 70-1, and the heat dissipation hole 2-1 Closed, the segmental exhaust is realized, so that the exhaust fan operates at low load, with low energy consumption and low noise.

Embodiment 3

[0044] On the basis of Example 1, a large amount of hot gas generated by cutting is discharged in two ways, one way is outer frame 70-2-rectangular hole 70-1-heat dissipation hole 2-1-left air duct 2-horizontal block 2 5-exhaust fan, the other one is the outer frame 70-2-rectangular hole 70-1-radiation hole 2-1-right air duct 3-horizontal brace 2 5-exhaust fan, compared with the prior art, the hot gas from The heat dissipation holes on both sides of the middle beam enter the middle beam at the same time and collide. After opening, the sealing plate 75 is cut and located in the heat dissipation hole 2-1, which plays a role of drainage, with small draft resistance, low-load operation of the exhaust fan, low energy consumption, and low noise. Small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com