Automatic plate feeding device

A technology of automatic feeding and sheet metal, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem that the sheet cannot be loaded one by one, achieve high reliability, low error rate, and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is further described in detail through specific implementation methods:

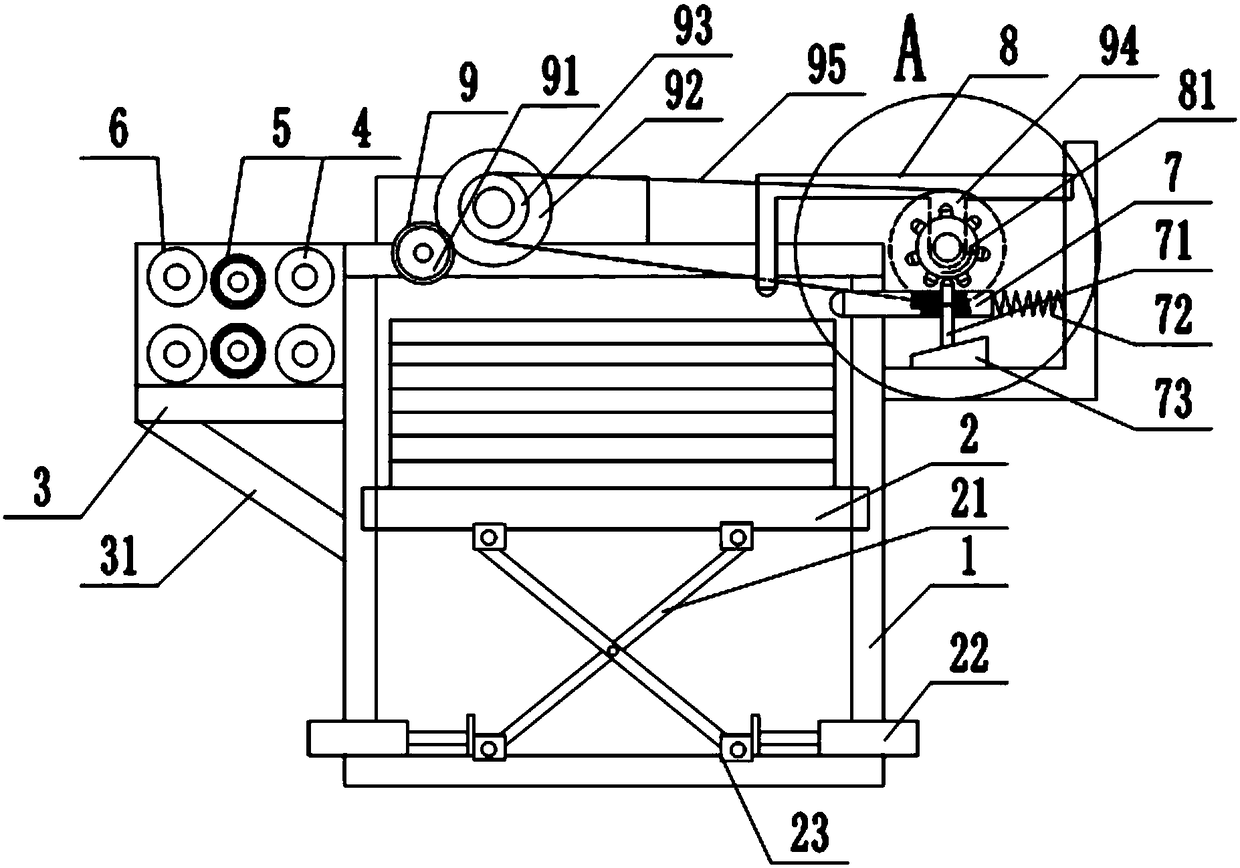

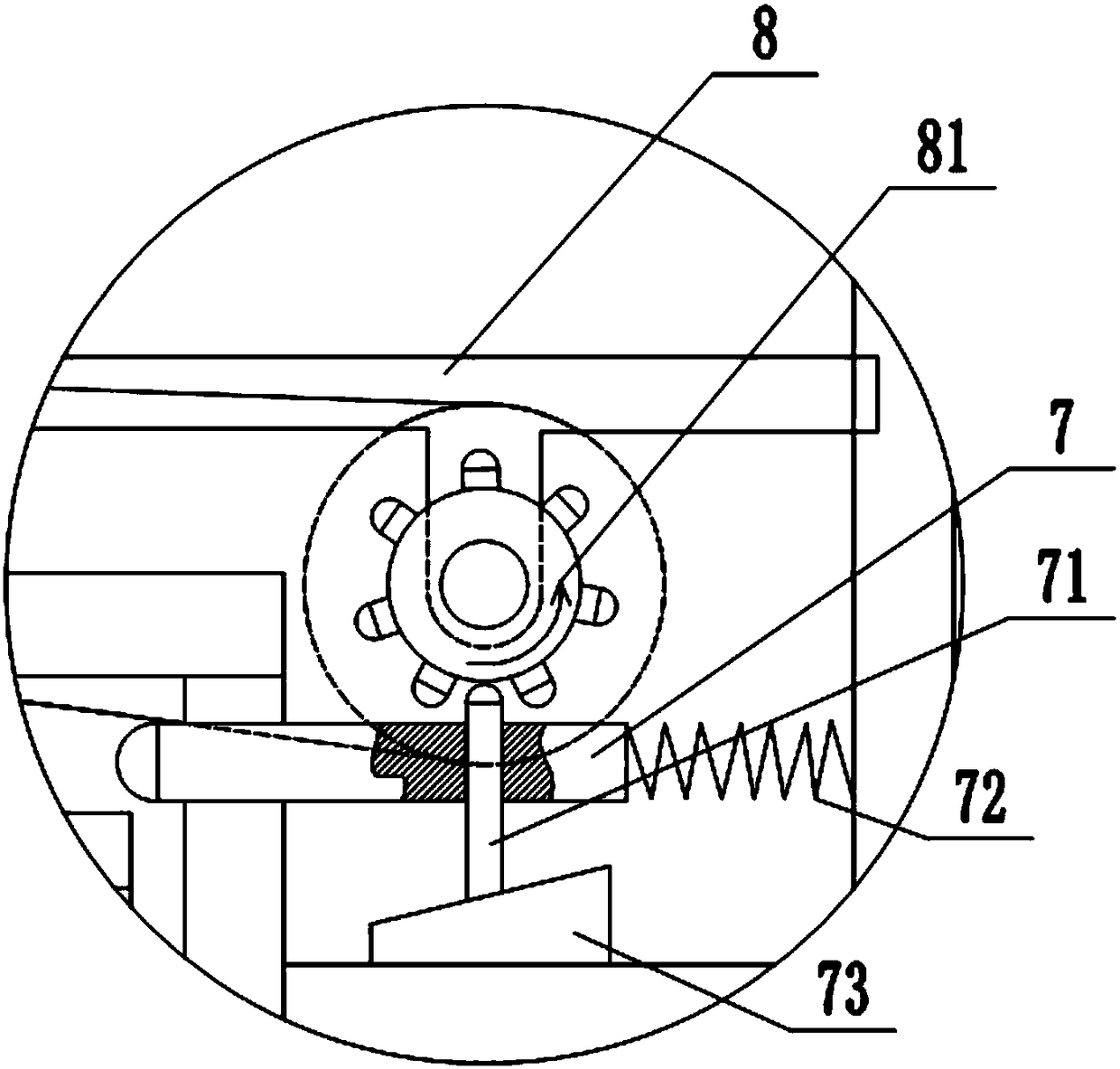

[0018] The reference signs in the drawings of the description include: frame 1, lifting plate 2, connecting rod 21, hydraulic cylinder 22, movable block 23, horizontal plate 3, inclined plate 31, input roller 4, cleaning roller 5, output roller 6, Push rod 7, latch 71, spring 72, wedge block 73, movable frame 8, gear 81, roller 9, driving wheel 91, driven wheel 92, first pulley 93, second pulley 94, belt 95.

[0019] The embodiment is basically as attached figure 1 and figure 2 Shown:

[0020] The automatic sheet material feeding device includes a frame 1, a lifting mechanism and a conveying mechanism. The lifting mechanism is installed in the frame 1, and the conveying mechanism is installed on the upper side of the frame 1. It also includes a pushing mechanism and a reset mechanism installed on the frame 1. mechanism, the push mechanism includes a push rod 7, a latch 71, and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com