Electrostatic-spun coated composite pelvic mesh and manufacturing method thereof

An electrospinning and patch technology, which is used in medical science, prostheses, incontinence prevention devices, etc., can solve the problems of excessive adhesion at the repair site, insufficient flexibility, and hard hand feeling of polypropylene, so as to increase flexibility and reduce erosion rate. , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

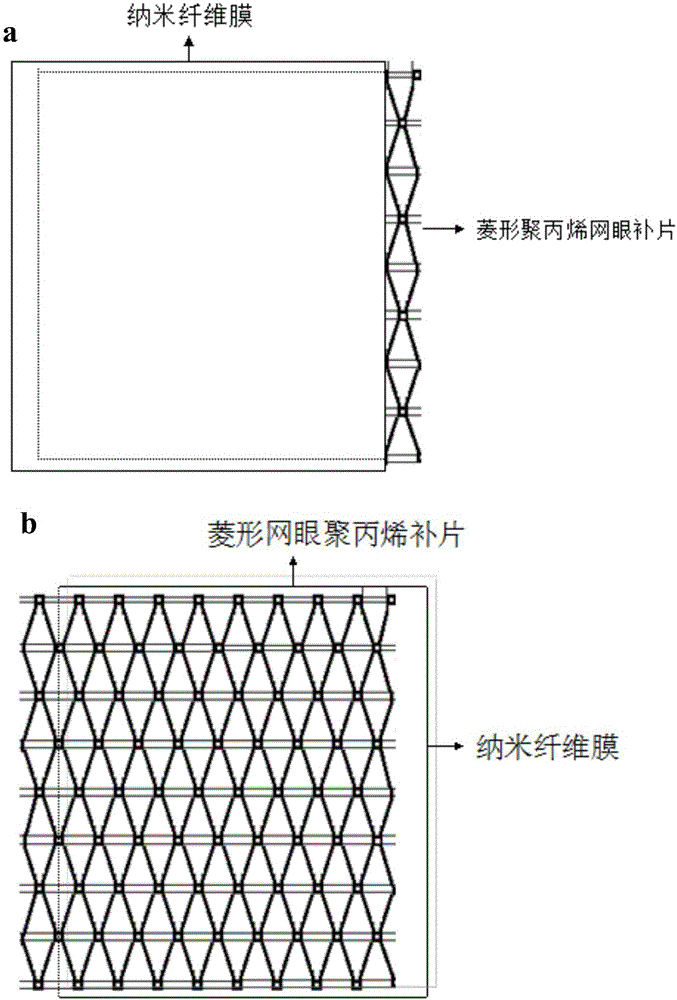

[0033] 1. Preparation of Polypropylene Rhomboid Mesh Patch

[0034] (1) Patch weaving: Use polypropylene monofilament with a diameter of 0.1mm as the raw material, and weave it on a three-bar Raschel warp knitting machine with a machine number of 20E to make a patch with a rhombic mesh structure. The yarn motion numbers are:

[0035] GB1:1-0 / 0-1 / / full wear

[0036] GB2:0-0 / 2-2 / 1-1 / 3-3 / 0-0 / 3-3 / 1-1 / 2-2 / 0-0 / 3-3 / / One wear one empty

[0037] GB3:3-3 / 1-1 / 2-2 / 0-0 / 3-3 / 0-0 / 2-2 / 1-1 / 3-3 / 0-0 / / One wear one empty

[0038] (2) Washing of patches: Gently rinse in cold water to remove surface impurities, and dry naturally at room temperature.

[0039] (3) Heat setting of the patch: the heat setting temperature is 130°C, and the heat setting time is 15 minutes.

[0040] 2. Configuration of electrospinning solution

[0041] Weigh 0.84g of polylactic acid granules and 0.36g of polycaprolactone granules into a screw-top glass bottle with a sealed cover, mix the DMC and DMF solutions evenly at a...

Embodiment 2

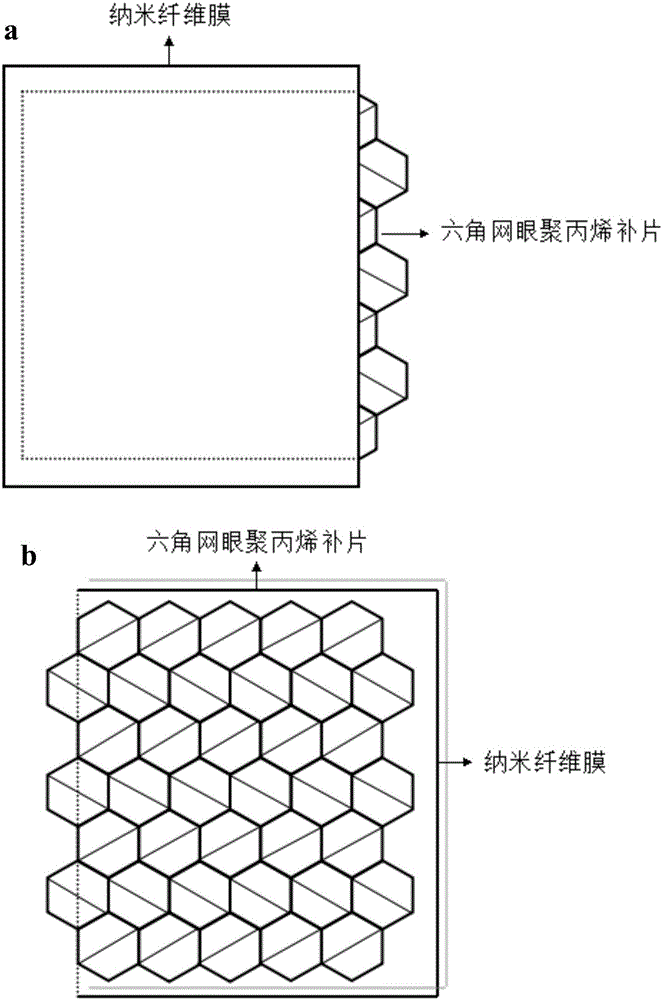

[0052] 1. Preparation of polypropylene hexagonal mesh patch

[0053] (1) Patch weaving: use polypropylene monofilament with a diameter of 0.1mm as the raw material, and weave it on a three-bar Raschel warp knitting machine with a machine number of 16E to make a patch with a hexagonal mesh structure. The yarn motion numbers are:

[0054] GB1: 2-3 / 2-1 / 2-3 / 1-0 / 1-2 / 1-0 / / 1 wear 1 empty

[0055] GB2: 1-1 / 1-0 / 1-0 / 2-2 / 2-3 / 2-3 / / 1 empty 1 wear

[0056] GB3: 1-0 / 1-2 / 1-0 / 2-3 / 2-1 / 2-3 / / 1 wear 1 empty

[0057] (2) Washing of patches: Gently rinse in cold water to remove surface impurities, and dry naturally at room temperature.

[0058] (3) Heat setting of the patch: the heat setting temperature is 130°C, and the heat setting time is 10 minutes.

[0059] 2. Configuration of electrospinning solution

[0060] Weigh 0.84g of polylactic acid granules and 0.36g of polycaprolactone granules into a screw-top glass bottle with a sealed cover, mix the DMC and DMF solutions evenly at a mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com