Full-automatic pipe cutting machine

A fully automatic, cutting machine technology, applied in metal sawing equipment, sawing machine equipment, metal processing equipment, etc., can solve the problems of low cutting efficiency, low cutting accuracy, and large labor, and achieve high cutting efficiency and labor. Small, labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

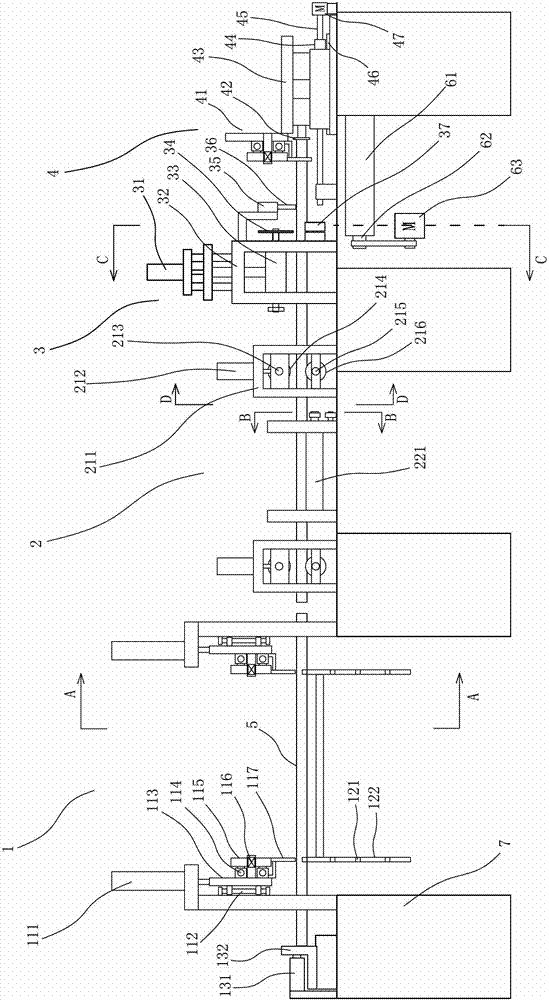

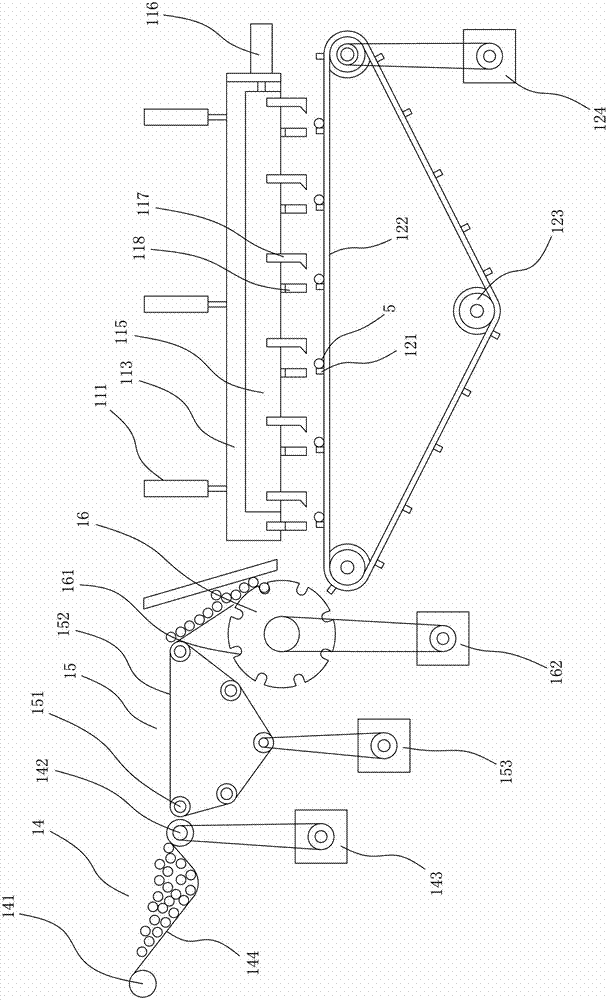

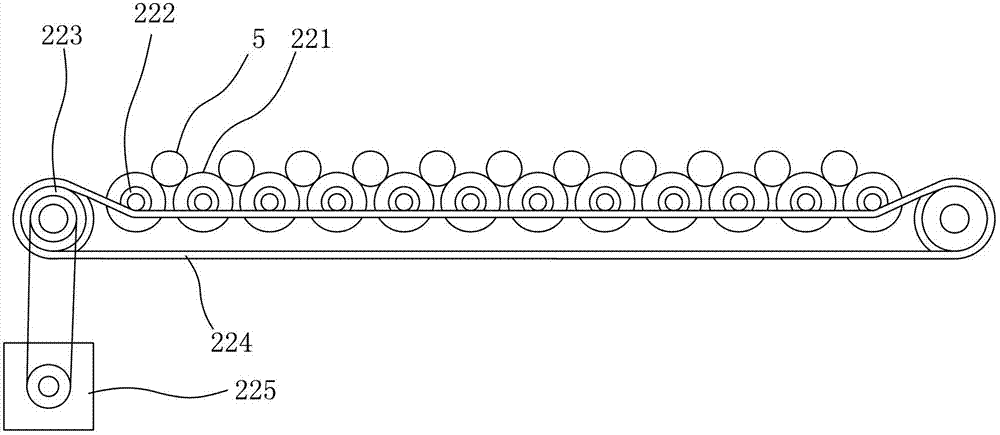

[0024] refer to Figure 1 to Figure 5 As shown, the automatic pipe cutting machine includes a frame 7, a feeding device 1, a feeding device 2, a cutting device 3, a measuring device 4 and a control device (not shown in the figure) which are arranged horizontally and horizontally on the frame 7 in turn. ), wherein the control device is respectively connected with each device for controlling the coordinated work of each device.

[0025] The cutting device 3 includes a tool holder 32 arranged on the frame 7, a plurality of first motors 33 arranged horizontally in the longitudinal direction and arranged on the tool holder 32 to move up and down, and a first motor 33 connected to drive each first motor 33 to move up and down synchronously. A cylinder 31, a circular saw blade 34 arranged on the output shaft of each first motor 33, a second motor (not shown in the figure) drivingly connected to the input shaft of each first motor 33 through a first transmission mechanism (not shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com