Novel coal mine high-strength anchor rod supporting device

A bolt support, high-strength technology, applied in mining equipment, bolt installation, earthwork drilling and mining, etc., can solve problems such as easy loosening, affecting support capacity, anchor rod breakage, etc., to improve connection performance and ensure Anchoring effect, effect of ensuring support capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

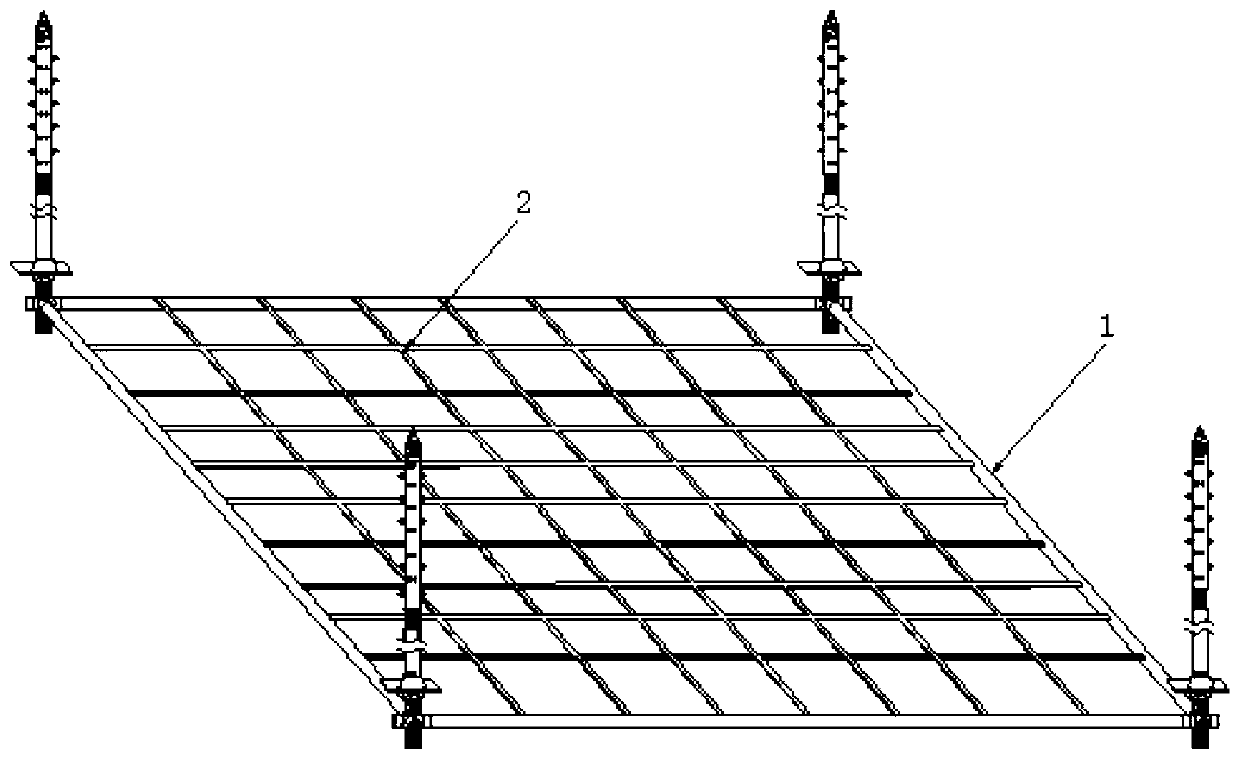

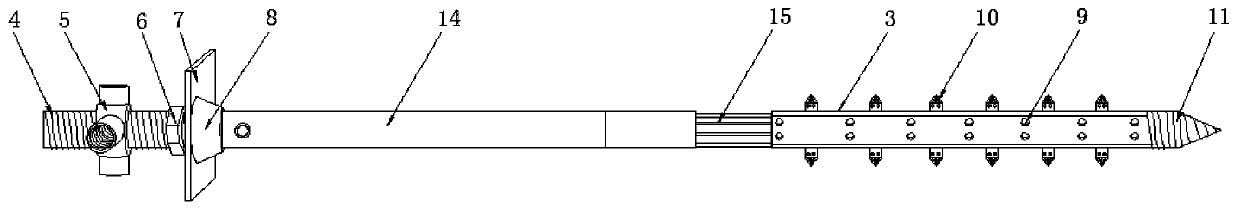

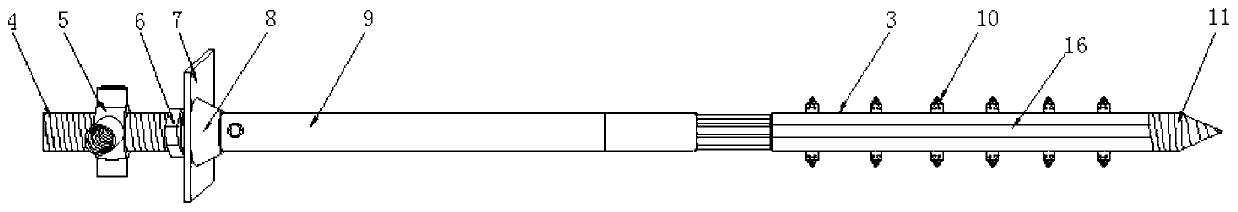

[0028] See Figure 1-9 In the embodiment of the present invention, a new type of high-strength bolt supporting equipment for coal mines includes a supporting bolt mechanism, a grouting equipment matched with the supporting bolt mechanism, and a supporting and anchoring net 2. The outer end of the supporting and anchoring rod mechanism is fixedly connected to the supporting and anchoring net, and the supporting and anchoring rod mechanism extends into the anchoring borehole, and the grouting equipment can inject the anchoring agent slurry into the anchoring borehole ; Its characteristic is,

[0029] The supporting anchor rod mechanism includes an outer anchor rod 14, an inner anchor sleeve 3, and an outer plugging and fixing component, wherein the inner anchor sleeve 3 extends into the innermost part of the anchoring borehole, and the outer anchor rod 14 The inner end of the outer anchor rod 14 can be sleeved in the inner anchor sleeve 3; the outer end of the outer anchor rod 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com