Heart valve prosthesis

A technology of heart valves and prostheses, applied in the field of medical devices, can solve problems such as unfavorable re-sheathing and re-recovery, emergency conversion to surgical thoracotomy, compression of surrounding tissues, etc., to achieve convenient re-sheathing and re-recovery, Elimination of the risk of suture breakage and the effect of stabilizing valve movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

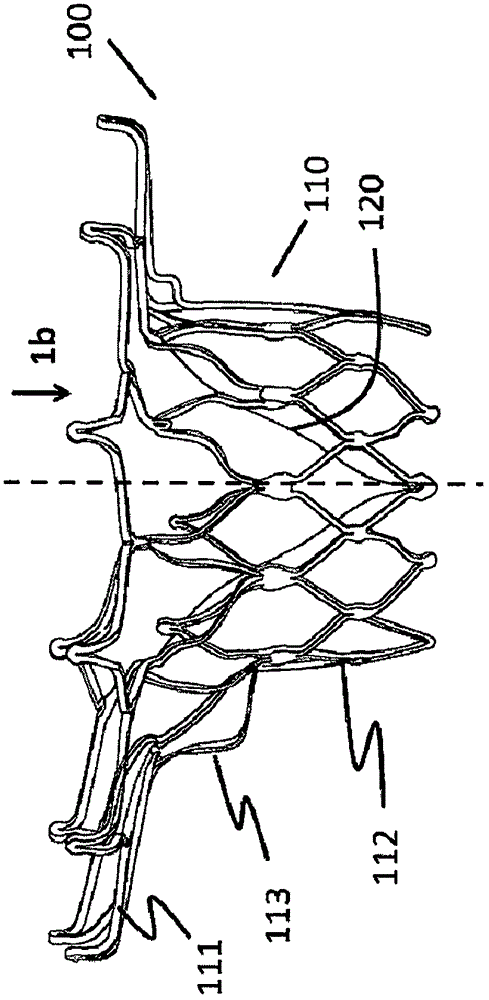

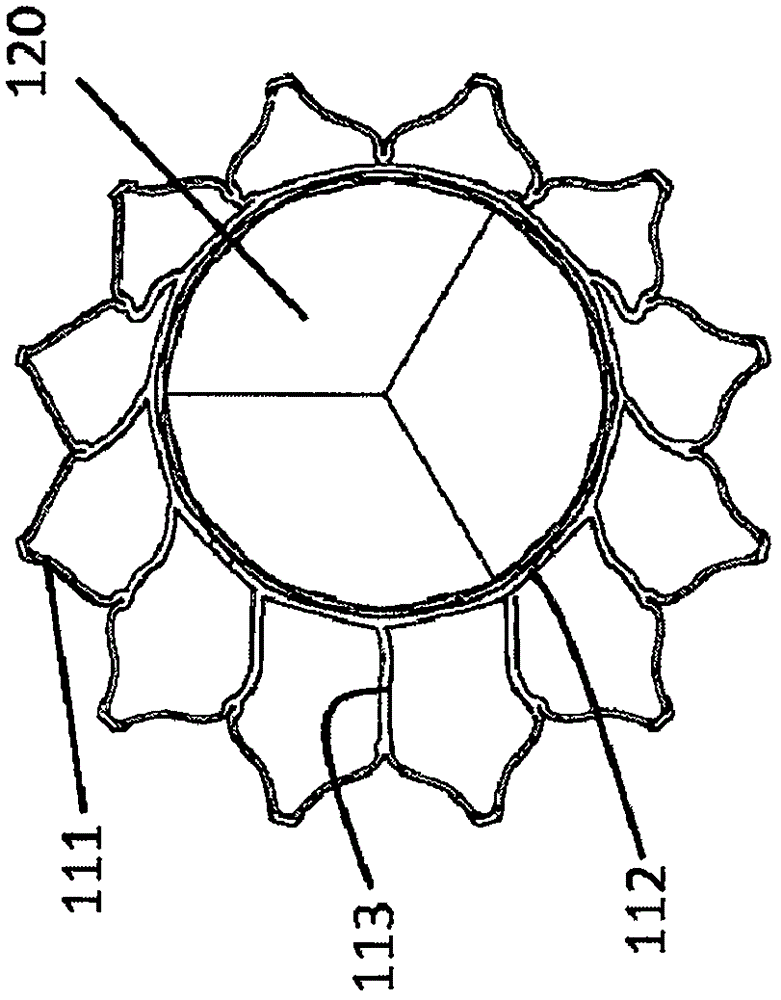

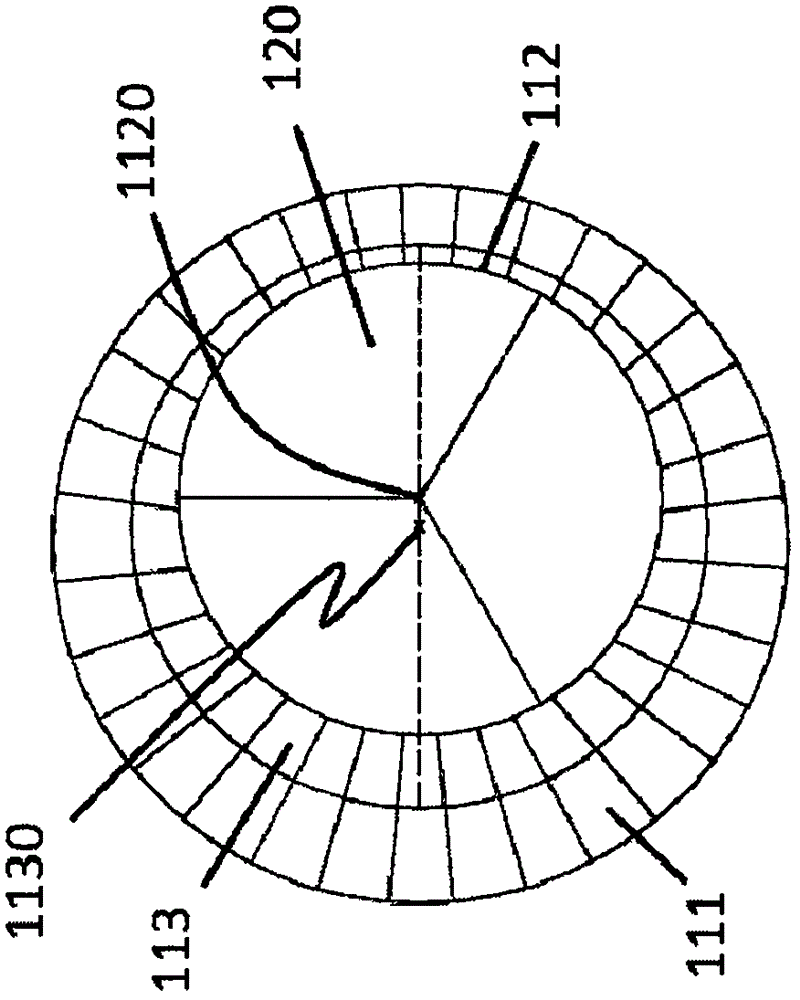

[0082] like Figure 1a As shown in -c, a heart valve prosthesis 100 includes a stent 110 and an artificial valve 120, the stent 110 includes an atrium segment 111 and a valve sewing segment 112, and the artificial valve 120 is fixedly connected to the valve sewing On the segment 112, the skeleton of the distal part of the valve sewing segment 112 extends to form a supporting segment 113, the supporting segment 113 is integrally structured with the valve sewing segment 112, and one end of the atrium segment 111 is connected to the The distal end of the support section 113 is connected, and the other end of the atrium section 111 is free. On a cross section perpendicular to the central axis of the artificial valve 120, the projection of the support section 113 is a ring structure, and the valve sewing section 112 is located in the support section 113, the center 1120 of the valve sewing section 112 does not coincide with the center 1130 of the support section 113, and the cross-...

specific Embodiment 2

[0087] like Figure 7a As shown in -c, a heart valve prosthesis 200 includes a stent 210 and an artificial valve 220, the stent 210 includes an atrium segment 211 and a valve sewing segment 212, and the artificial valve 220 is fixedly connected to the valve sewing On the segment 212, the skeleton of the distal part of the valve sewing segment 212 extends to form a support segment 213, and the support segment 213 is integrated with the valve sewing segment 212. Layer brackets are processed separately and then overlapped, stitched and connected. The one-piece structure of the present invention reduces the diameter of the sheath on the one hand, and on the other hand, the design without steps makes re-sheathing and re-recovering more convenient, and finally eliminates It reduces the risk of suture breakage and improves safety. One end of the atrium segment 211 is connected to the distal end of the support segment 213, and the other end of the atrium segment 211 is free. On a cro...

specific Embodiment 3

[0096] As shown in Fig. 13a-e, a heart valve prosthesis 300 includes a stent 310 and an artificial valve (not shown), the stent 310 includes an atrium section 311 and a valve sewing section 312, and the artificial valve is fixedly connected to On the valve sewing section 312, the skeleton of the distal part of the valve sewing section 312 extends to form a supporting section 313, and the supporting section 313 is integrally structured with the valve sewing section 312. The atrium section 311 One end of the support segment 313 is connected to the distal end, and the other end of the atrium segment 311 is free. On a cross section perpendicular to the central axis of the artificial valve, the projection of the support segment 313 is a ring structure. The valve sewing section 312 is located in the support section 313, the center of the valve sewing section 312 does not coincide with the center of the support section 313, and the cross-sectional area of the support section 313 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com