Anti-coagulation stainless steel coronary arterial bracket and uses thereof

A stainless steel, anti-coagulation technology, applied in the field of medical devices, can solve the problems of aggravating inflammation and increasing stent restenosis, achieve good flexibility, reduce restenosis rate and thrombosis, and avoid postoperative restenosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

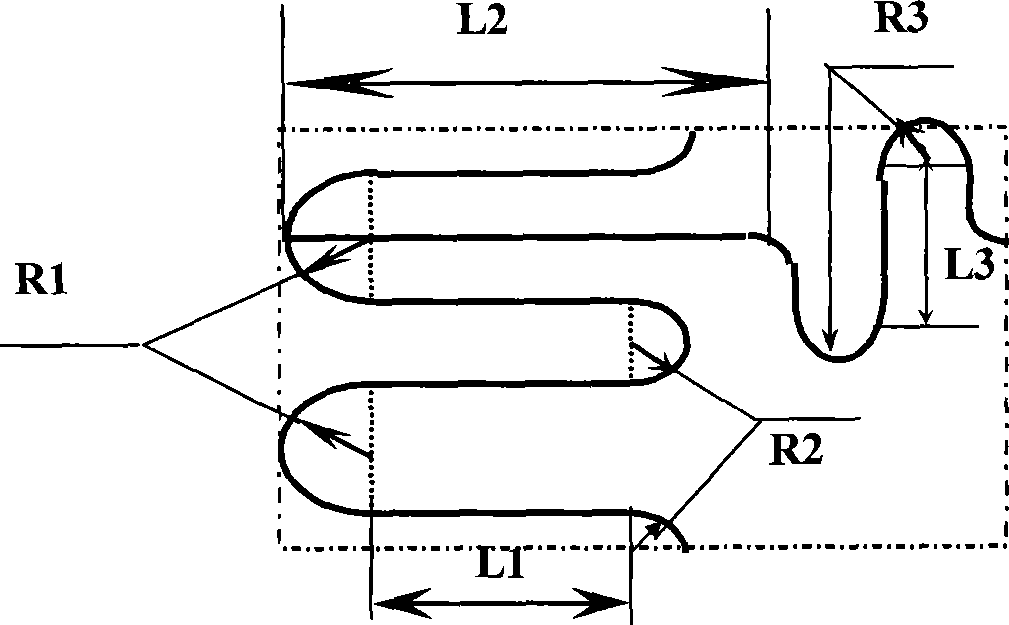

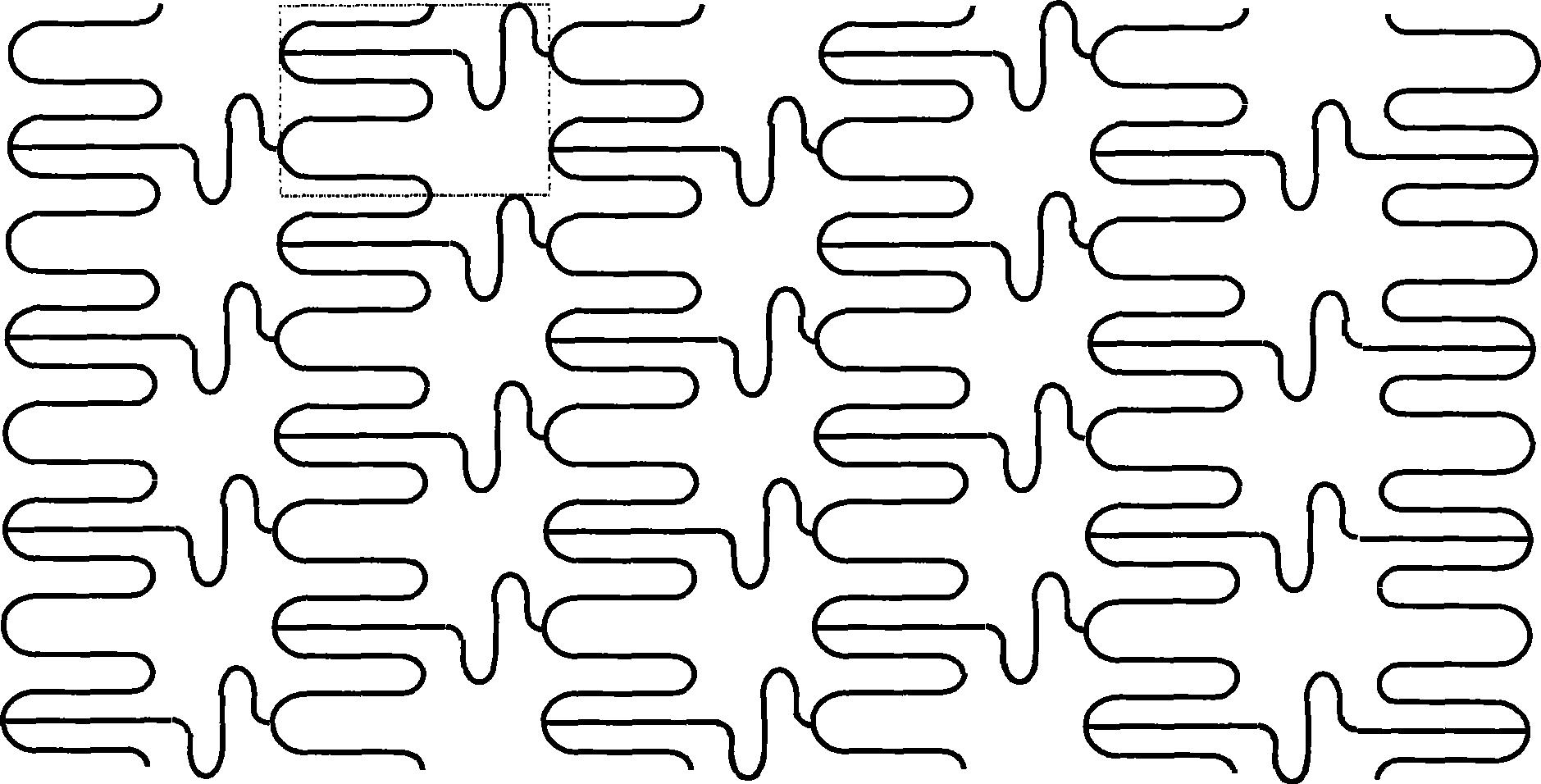

Image

Examples

Embodiment 1

[0032] High-nitrogen nickel-free stainless steel HNS1 (see Table 1) was used to make coronary stent samples (after polishing, the average wire diameter was 70 μm ± 5 μm), ultrasonically cleaned in acetone and alcohol for 5 minutes, and passivated in concentrated nitric acid for 30 minutes , and then kept in an oven at 80°C for 6 hours. Then put the stent into a drug-containing solution in tetrahydrofuran (containing 0.1% paclitaxel) with a mass concentration of 1% polymethyl methacrylate, soak for 30 minutes, quickly lift the stent, and centrifuge at 500rpm for 1 minute After carefully cleaning the coating on the inner surface of the stent, evenly coat the inner surface with a solution containing 20% mass concentration of endothelial growth factor (VEGF), then put it in a vacuum drying oven at 90°C for 30 minutes, and cool to room temperature with the furnace .

Embodiment 2

[0034] High-nitrogen nickel-free stainless steel HNS2 (see Table 1) was used to make coronary stent samples (after polishing, the average wire diameter was 55 μm ± 5 μm), ultrasonically cleaned in acetone and alcohol for 5 minutes, and passivated in concentrated nitric acid for 30 minutes , and then kept in a 70°C drying oven for 8 hours. Then put the stent in the spraying device, and use the spray gun to spray the colloid containing medicaments in tetrahydrofuran (containing 0.05% rapamycin) with a mass concentration of 0.8% polytetrafluoroethylene to the outer surface of the stent several times, and the inner The surface was protected with a built-in core, and then a solution containing 30% endothelial growth factor (VEGF) was uniformly coated on the inner surface, and finally the scaffold was dried in a vacuum oven at 60°C for 12 hours.

Embodiment 3

[0036] High-nitrogen nickel-free stainless steel HNS3 (see Table 1) was used to make coronary stent samples (after polishing, the average wire diameter was 45 μm ± 5 μm), ultrasonically cleaned in acetone and alcohol for 5 minutes, and passivated in concentrated nitric acid for 30 minutes , and then kept in a 100°C drying oven for 5 hours. Then put the stent in the spraying device, use the spray gun to spray the colloid containing medicaments in tetrahydrofuran (containing 0.08% heparin) with a mass concentration of 3% polyglycolide to the outer surface of the stent several times, and the inner surface is sprayed with a built-in Then, the inner surface was uniformly coated with a solution containing 40% endothelial growth factor (VEGF), and finally the scaffold was dried in a vacuum oven at 50°C for 20 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com