Amino- and thiol-modified magnetic carbon nanotube composite material and preparation method

A technology of magnetic carbon nanotubes and carbon nanotubes, which is applied in the field of nanomaterials, can solve the problems of low efficiency of functional groups, poor dispersion of carbon nanotubes, and low degree of functionalization, and achieve simple process, favorable adsorption, and excellent magnetic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

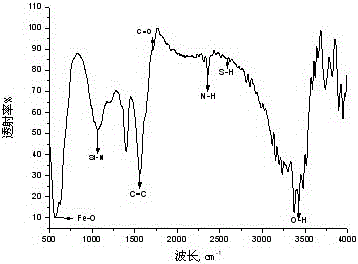

[0017] The preparation method of the magnetic carbon nanotube composite material modified by amino group and thiol group, the steps are:

[0018] (1) Disperse the carbon nanotubes into the mixed acid solution, react at 60-80°C for 1-3 hours for pretreatment, then filter, wash and dry for later use;

[0019] (2) Add pretreated carbon nanotubes to the solution containing ferrous ions and ferric ions. After ultrasonic oscillation for 10-30 minutes, add ammonia water drop by drop to control the pH at 11-12. Stir for 30 to 60 minutes, wherein the mass ratio of the pretreated carbon nanotubes to ammonium ferrous sulfate is 1:2 to 1:10;

[0020] (3) Separate the generated magnetic carbon nanotubes with a magnet, and dry them in a vacuum oven at 60-120°C for 6-20 hours to obtain superparamagnetic carbon nanotube materials;

[0021] (4) Disperse the supermagnetic carbon nanotube material in absolute ethanol, stir mechanically under the protection of nitrogen, add acetic acid and 3-mer...

Embodiment 1

[0030] Step 1 carbon nanotube pretreatment:

[0031] Disperse 1g of original multi-walled carbon nanotubes (prepared by chemical vapor deposition) into a mixed acid solution of 60ml concentrated sulfuric acid and 20ml concentrated nitric acid, stir and react at 60°C for 3 hours, wash with distilled water until pH = 7, and vacuum dry at 80°C Reserve after 12 hours.

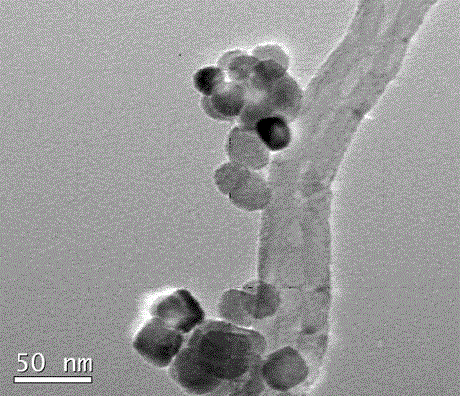

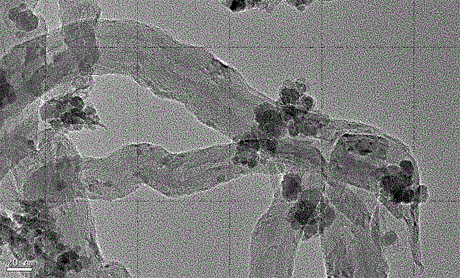

[0032] Step 2 Preparation of superparamagnetic carbon nanotube material MagCNTs:

[0033] 0.1 g of pretreated multi-walled carbon nanotubes were added to a mixed solution of 0.17 g ferrous ammonium sulfate and 0.25 g ferric ammonium sulfate, and ultrasonically oscillated for 10 minutes; 8 mol / L ammonia solution was added dropwise, and the mixed solution was The pH is controlled at 11-12; the generated superparamagnetic carbon nanotube material is separated from the suspension with a magnet, washed 5 times with distilled water; vacuum-dried at 80 degrees for 8 hours, dried and ground for later use to obtain superpa...

Embodiment 2

[0039] Step 1 carbon nanotube pretreatment:

[0040] Put 0.3g of original multi-wall carbon nanotubes (prepared by chemical vapor deposition) into a sand core funnel with a pore size of 20-30 microns, and place the sand core funnel with original multi-wall carbon nanotubes in a volume of 50 ml In the Teflon container, there is 3ml of concentrated nitric acid at the bottom of the Teflon container, put the Teflon container into a reaction kettle with a volume of 100ml, seal it, and then put it into the drying box, the temperature of the drying box is 200°C, duration is 5 hours. Take out the reaction kettle to cool to room temperature, open the reaction kettle and take out the sand core funnel, put the carbon nanotubes into a clean beaker, dilute with 100ml of distilled water, pour the diluted carbon nanotubes into a 10 cm diameter beaker with ordinary filter paper Wash the funnel 10 times with water and absolute ethanol until the pH of the washing water is close to neutral. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com