Laser rapid repairing method for high chromium cast steel roller surface layer fatigue micro cracks

A technology of high-chromium cast steel and a repair method, which is applied in the innovative technical field of material surface treatment methods, can solve the problem of repairing micro-cracks on the surface of high-chromium cast steel materials, the problem of laser surface strengthening, affects the service life of the roll, and the surface is easy to appear. Cracks and other problems, to solve the effect of quick repair, uniform hardness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment one: Laser rapid repair and surface strengthening of fatigue microcracks on the surface of high chromium cast steel rolls

[0037]First of all, the high chromium cast steel roll is used as the treatment object. The fatigue microcrack depth on the surface of the high chromium cast steel is less than 0.4mm. Degrease steel surfaces.

[0038] Secondly, the light-absorbing paint was uniformly sprayed on the surface of the high-chromium cast steel material with the Japanese Iwata W-77 spray gun. The thickness of the light-absorbing paint sprayed layer was about 0.05mm. The preheating temperature is 150°C.

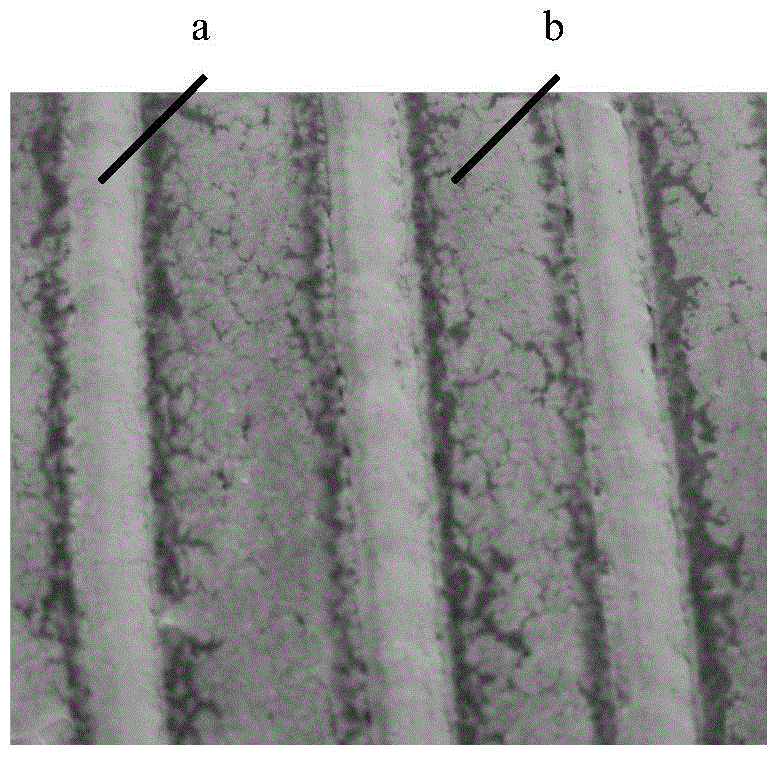

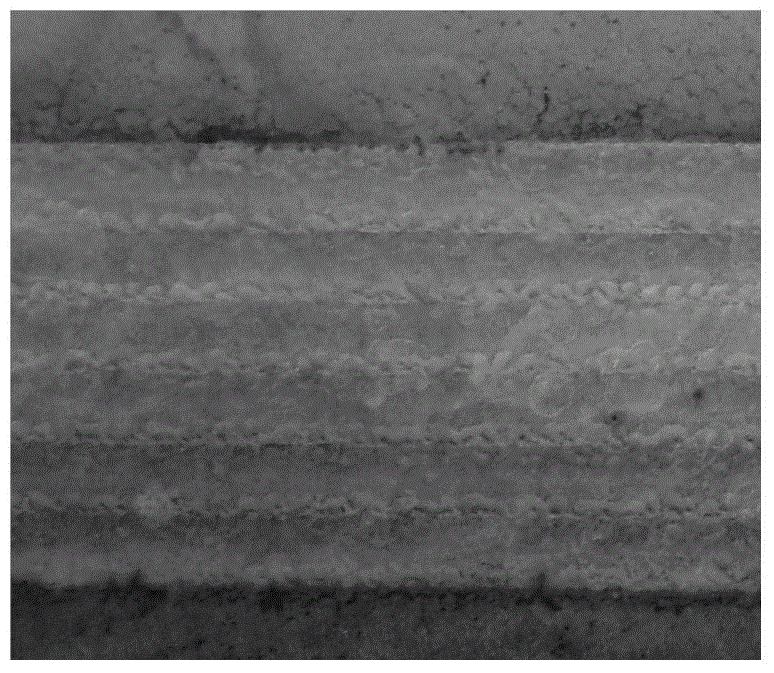

[0039] Then adopt the continuous overlapping method to carry out laser rapid melting treatment. The specific process parameters are: using 5kW cross-flow CO 2 Laser processing system, the spot size is Φ3mm, the power is 2700W, and the scanning speed is 300mm / min, the overlap is 1.0mm, and the surface of the high chromium cast steel material is continuously ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com