Bainite type rail excellent in surface fatigue damage resistance and wear resistance

A technology of fatigue damage and bainite, applied in the field of high-strength bainite steel rails, can solve the problems of bainite structure toughness reduction, spalling and other delamination damage, and wear resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] Certain embodiments of the present invention will be described below.

[0070]

rails

refer to

letter

Chemical composition (weight percent)

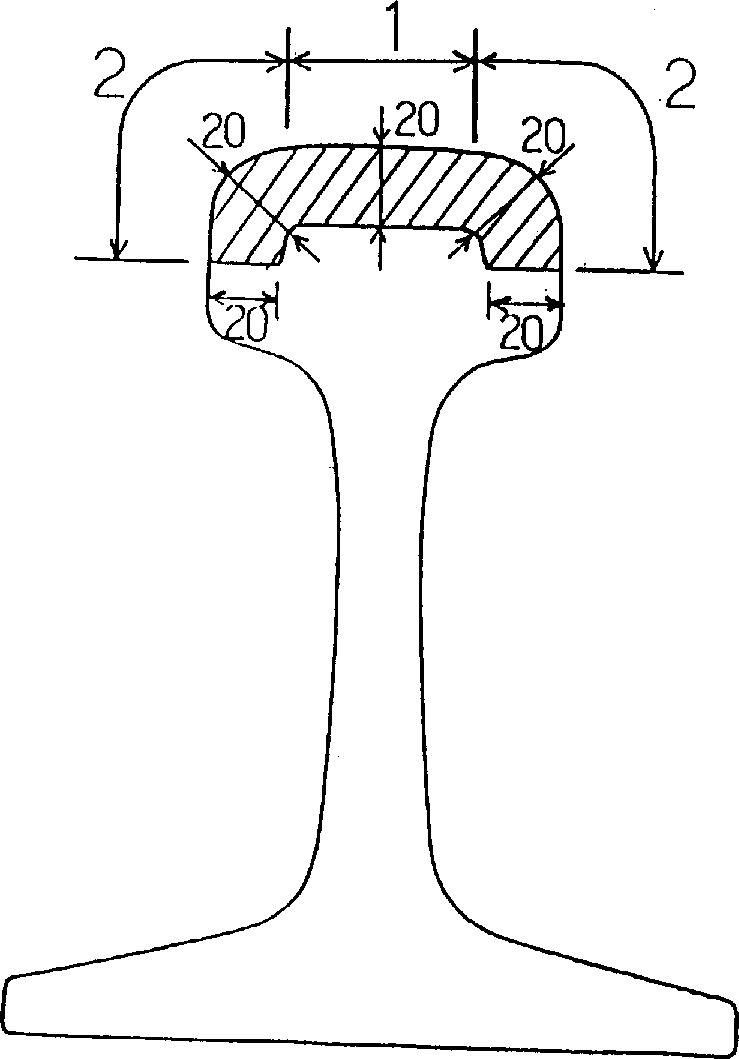

rail head

on a given section

Carbide major axis range

Area occupied on a given section (%)

rail head

Wear (g / 50×10 4 Second-rate)

surface fatigue damage

Incidence rate (×10 4 Second-rate)

C

Si

mn

Cr

Other Alloy Additives

* Maximum~Minimum(nm)

Book

send

bright

steel

track

A

0.17

1.82

1.45

1.21

B:0.017

200~2600

11

1.51

200, no damage

B

0.22

0.35

2.91

0.64

V:0.04

150~1600

18

0.81

200, no damage

C

0.22

0.81

0.84

2.84

Nb: 0.04

Ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com