Method for repairing roller sleeve of continuous casting roller

A repair method and continuous casting roll technology, which is applied in the direction of welding media, laser welding equipment, welding/cutting media/materials, etc., can solve problems such as increased production costs, reduced precision of casting machines, and damage to roll sleeves, so as to reduce maintenance costs , Improve production efficiency, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

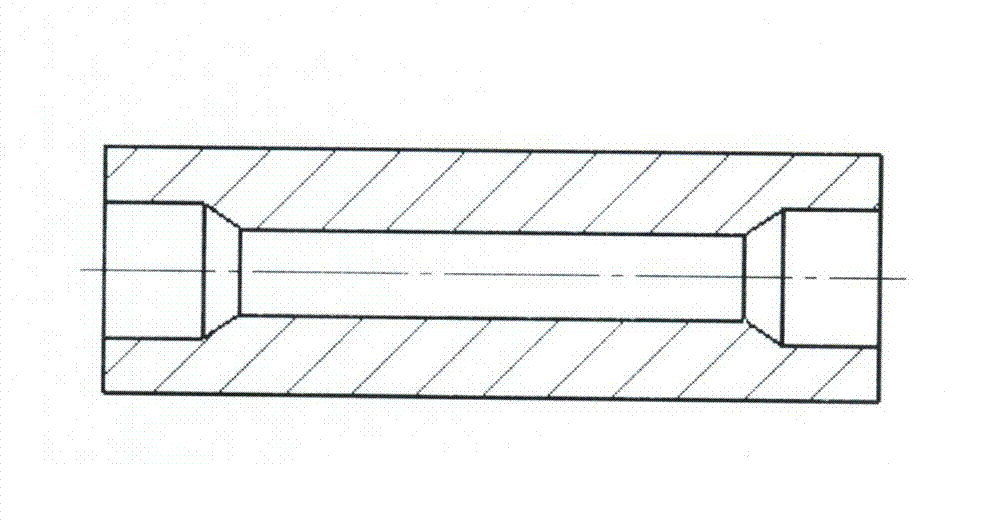

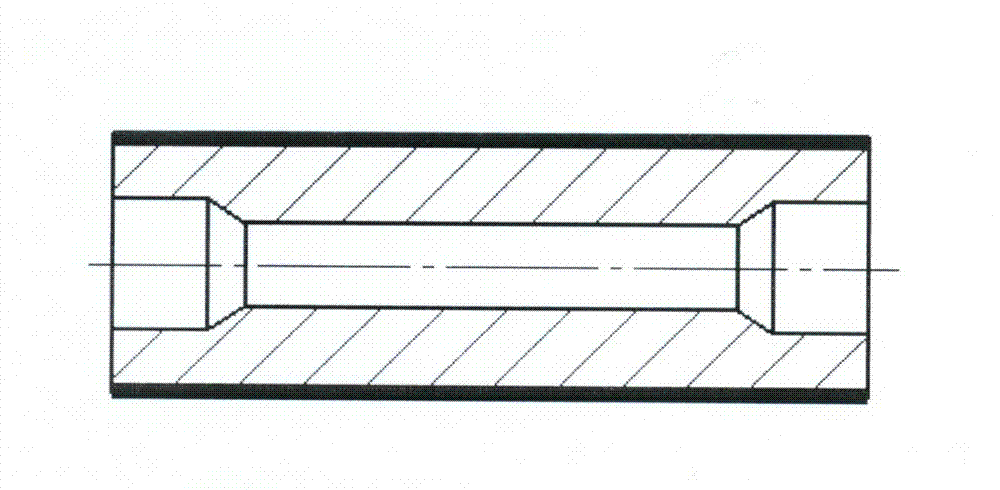

[0024] Example 1 Taking the continuous casting roll sleeve repaired with a material of 35CrMo and a size of φ230mm×618mm as an example, firstly, a preliminary inspection is performed on the roll sleeve whose material is 35CrMo to be repaired; figure 1 As shown, measure the size of each part of the roller sleeve to check whether it is suitable for the laser cladding repair standard, and then use the turning method to remove the 3mm fatigue layer on the surface of the roller sleeve, and conduct magnetic particle inspection and ultrasonic flaw detection to ensure that the surface of the roller sleeve and the base material are free of serious cracks. For defects, the outer diameter of the roller sleeve is processed to φ224mm; the proportionally prepared Ni45 and WC powders are put into a mechanical powder mixer and fully mixed by a mechanical mixing method. The mixing time is 1.5 hours, and the mixing ratio of the alloy powder is : Ni45 powder accounts for 75% of the total mass, a...

Embodiment 2

[0025] Example 2 Taking the repair of the continuous casting roll sleeve made of 42CrMo and with a size of φ230mm×618mm as an example, first, a preliminary inspection is carried out on the roll sleeve made of 42CrMo material to be repaired; the dimensions of each part of the roll sleeve are measured to see if it is suitable for laser melting. Then use the turning method to remove the 3mm fatigue layer on the surface of the roller sleeve, conduct magnetic particle inspection and ultrasonic flaw detection to ensure that there are no serious defects such as cracks on the surface of the roller sleeve and the base material, and process the outer diameter of the roller sleeve to φ224mm; use mechanical mixing Methods The Ni45 and WC powders prepared in proportion were put into a mechanical powder mixer and mixed fully. The mixing time was 1.5 hours. The mixing ratio of the alloy powder was: Ni45 powder accounted for 80% of the total mass, and WC powder accounted for 80% of the total ma...

Embodiment 3

[0026] Example 3 Taking the repair of a continuous casting roll sleeve made of 42CrMo and with a size of φ150mm×600mm as an example, a preliminary inspection is performed on the roll sleeve made of 42CrMo to be repaired; Then use the turning method to remove the 2mm fatigue layer on the surface of the roller sleeve, conduct magnetic particle inspection and ultrasonic flaw detection to ensure that there are no serious defects such as cracks on the surface of the roller sleeve and the base material, and process the outer diameter of the roller sleeve to φ146mm; use mechanical mixing Methods Put the Ni45 and WC powder prepared in proportion into a mechanical powder mixer and mix them thoroughly. The mixing time is 2 hours. The mixing ratio of the alloy powder is: Ni45 powder accounts for 80% of the total mass, and WC powder accounts for 80% of the total mass. 20%, preheat the 42CrMo roller sleeve to be clad to 350°C, adopt the coaxial powder feeding method, the powder transmission...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com