Laser surface intensified technique for roller of rolling section bar

A technology of surface strengthening and rolling, applied in the direction of rolling, metal rolling, manufacturing tools, etc., can solve the problems of large capital occupation, long production cycle, large inventory, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

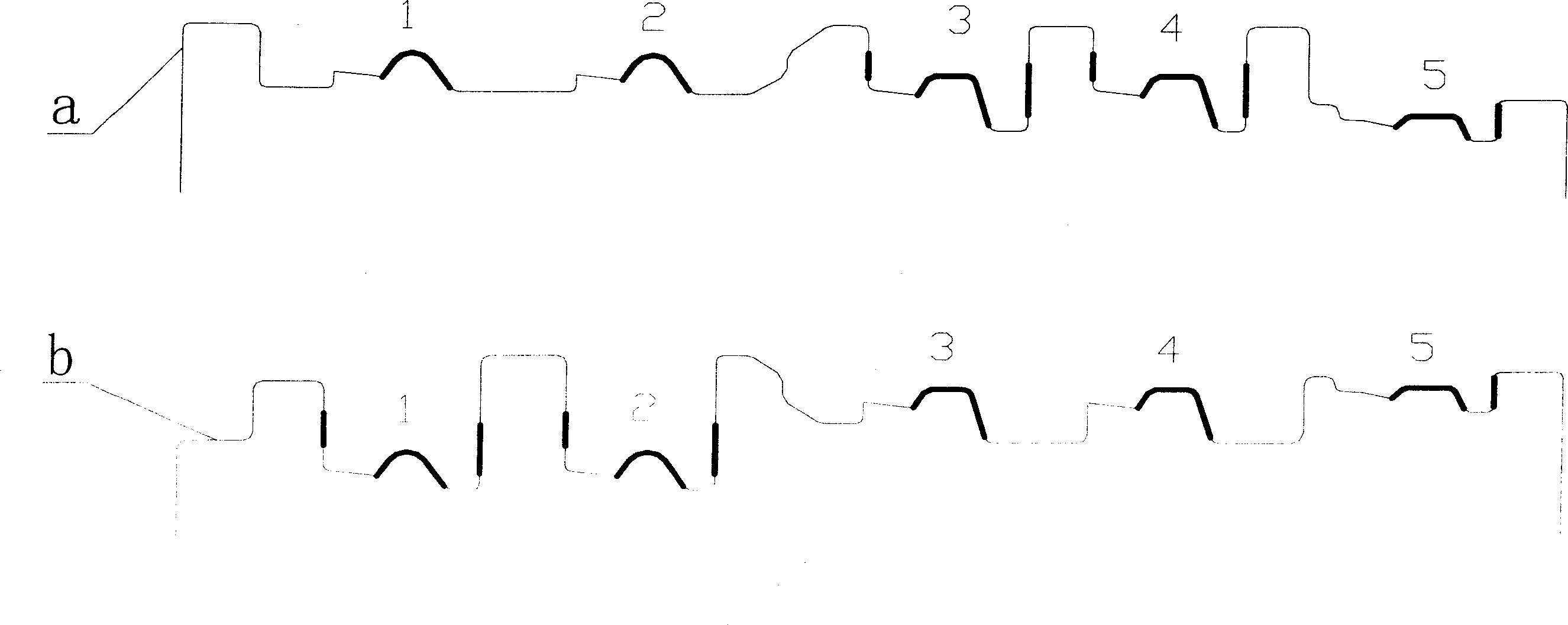

Image

Examples

Embodiment Construction

[0008] In view of the commonality of the working conditions of various rolls, the process of rolling 60Kg / m heavy rails with BD2 rolls is taken as an example. This process can be popularized and used in 75Kg / m, 50Kg / m, and 43Kg / m heavy rails on the roll.

[0009] Strengthening adopts roll turning processing, flaw detection inspection, surface pretreatment, and laser strengthening treatment process.

[0010] 1. Roll turning

[0011] Before the laser surface strengthening treatment, the fatigue layer on the surface of the BD2 roll should be turned clean, so as to avoid uneven protruding lumps due to rapid heating and cooling during laser surface treatment, which will affect the rolling quality and small pieces of spalling during steel rolling .

[0012] 2. Flaw detection inspection

[0013] After turning, the BD2 rolls should be inspected for flaw detection, and the surface cracks of the rolls should be inspected with a magnetic particle flaw detector. The rolls with circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com