Surface fatigue crack detecting method based on CCD image characteristic

A technology of fatigue cracks and image features, which is applied in the direction of optical testing for defects/defects, can solve the problems of cumbersome implementation, expensive equipment, and the need to contact samples, and achieve the effects of fast detection speed, low cost, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0045] Such as Figure 1-4 shown.

[0046] A kind of image detection method of surface fatigue crack, it comprises the following steps:

[0047] Step 1: Carry out fatigue crack growth test on the sample and collect digital images;

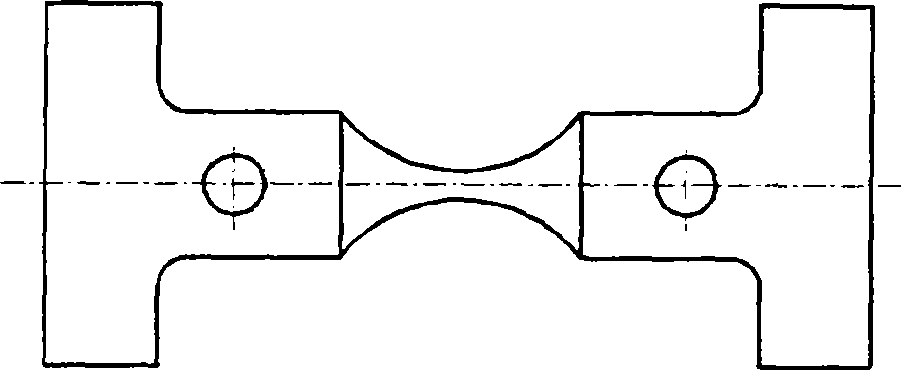

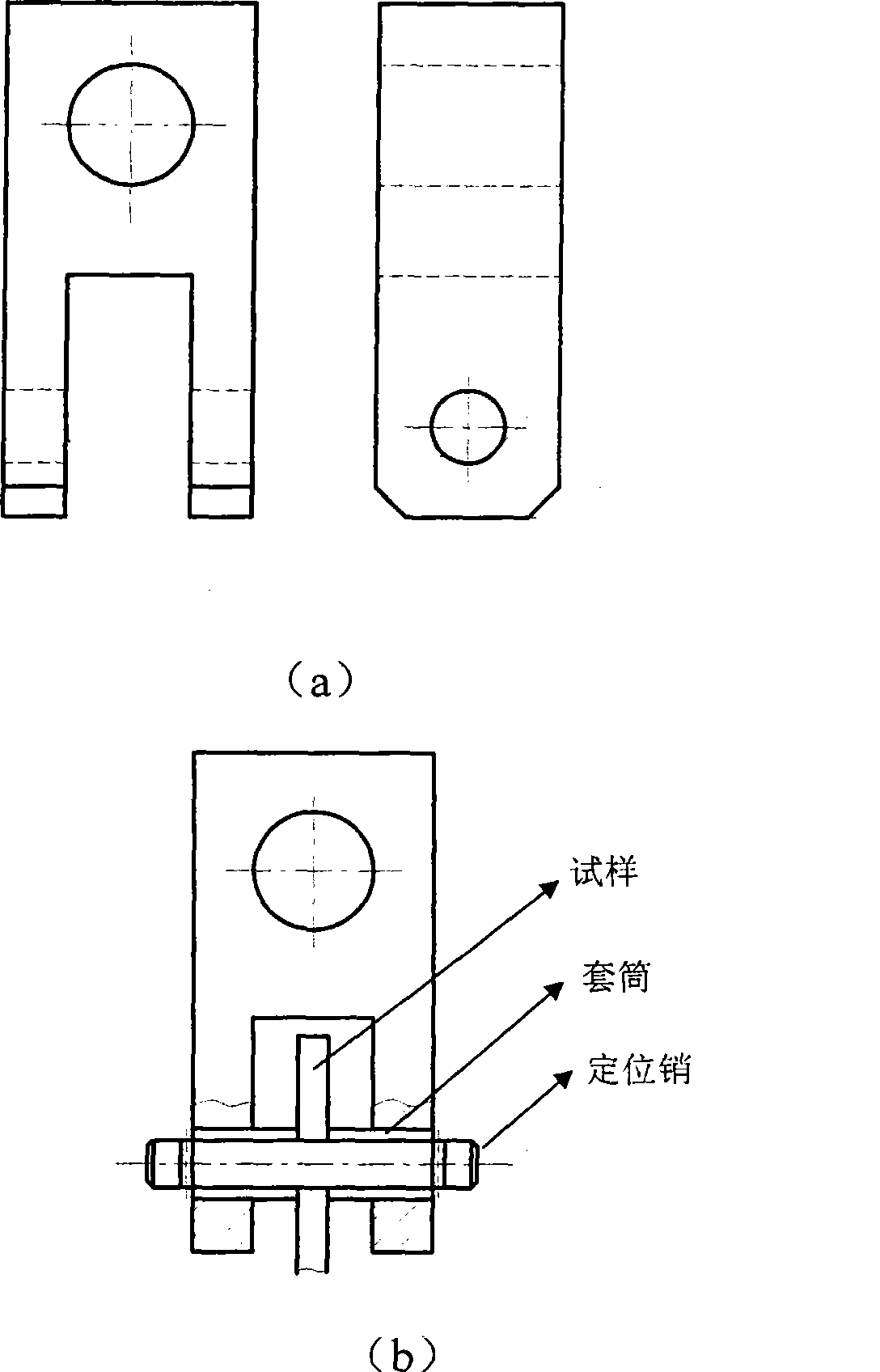

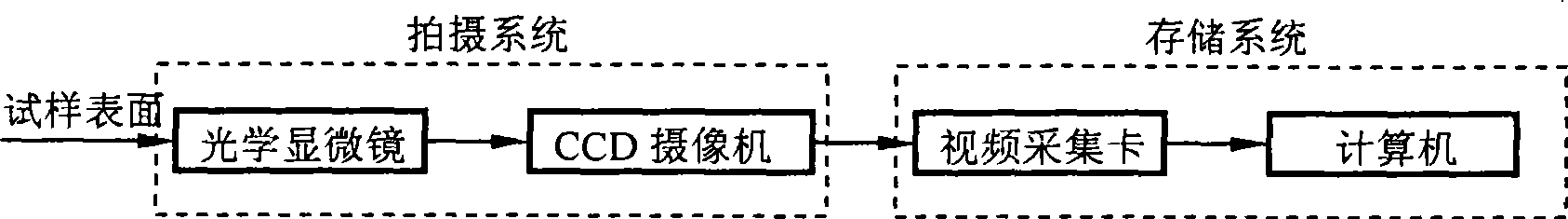

[0048] Sample such as figure 1 As shown, the clamping scheme is as follows figure 2 shown. Using self-designed image acquisition system (such as image 3 (shown) to collect (continuously collected during the whole test process or regularly collected at regular intervals) images of the surface fatigue crack growth process, and analyze the surface fatigue cracks using the surface replica method to obtain the length of each stage of the surface fatigue crack growth, according to The number of vibrations of the fatigue testing machine and the corresponding surface fatigue crack length, the length growth curve (a-N curve and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com