Heat treatment technology for bearing ferrule

A bearing ring and process technology, applied in the field of bearing ring heat treatment technology, can solve problems such as decomposition and bearing size change, and achieve the effects of delaying crack propagation, enhancing stability, and alleviating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

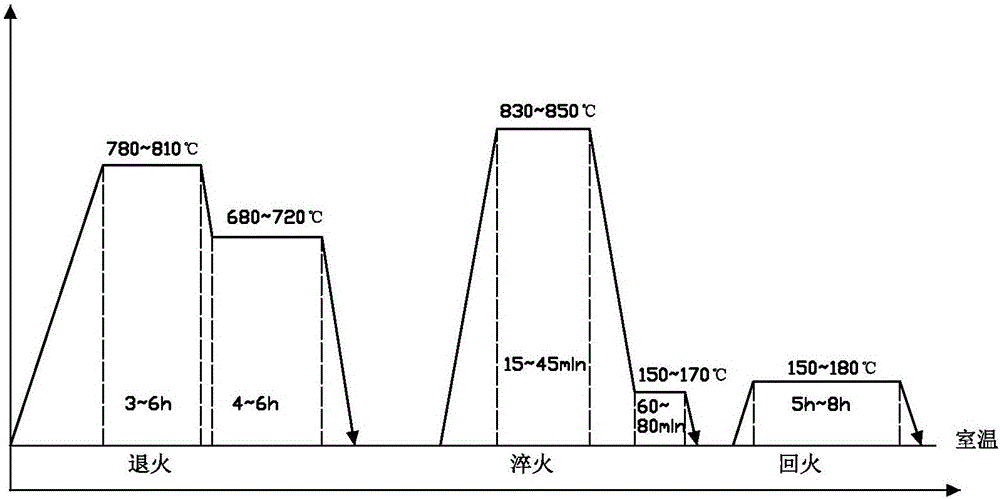

[0018] like figure 1 Shown is the process flow of the present invention, which is carried out according to the following steps: ①Spheroidizing annealing: raise the temperature to 780°C in the furnace, keep warm for 5h for annealing, then keep warm for 5h at 710°C, and then heat at 30°C / h The cooling speed furnace is cooled to 650 ℃ and air-cooled;

[0019] ②Quenching + Tempering, use 845°C, hold for 40 minutes, conduct a 160°C salt bath isothermal for 65 minutes, then take it out and air-cool, air-cool to room temperature, and then temper at 170°C for 6 hours.

Embodiment 2

[0021] like figure 1 Shown is the process flow of the present invention, which is carried out according to the following steps: ①Spheroidizing annealing: raise the temperature to 800°C in the furnace, keep warm for 6h for annealing, then keep warm for 6h at 720°C, and then use 30°C / h The cooling speed furnace is cooled to 650 ℃ and air-cooled;

[0022] ②Quenching + Tempering: Use 850°C, hold for 45 minutes, perform 160°C salt bath isothermal for 75 minutes, then take it out and air-cool, air-cool to room temperature, and then temper at 160°C for 8 hours.

Embodiment 3

[0024] like figure 1 Shown is the process flow of the present invention, which is carried out according to the following steps: ①Spheroidizing annealing: raise the temperature to 810°C in the furnace, keep warm for 4h for annealing, then keep warm for 5h at 690°C, and then use 30°C / h The cooling speed furnace is cooled to 650 ℃ and air-cooled;

[0025] ②Quenching + Tempering: Use 835°C, hold for 30 minutes, perform 150°C salt bath isothermal for 60 minutes, then air-cool, air-cool to room temperature, and then temper at 150°C for 6 hours.

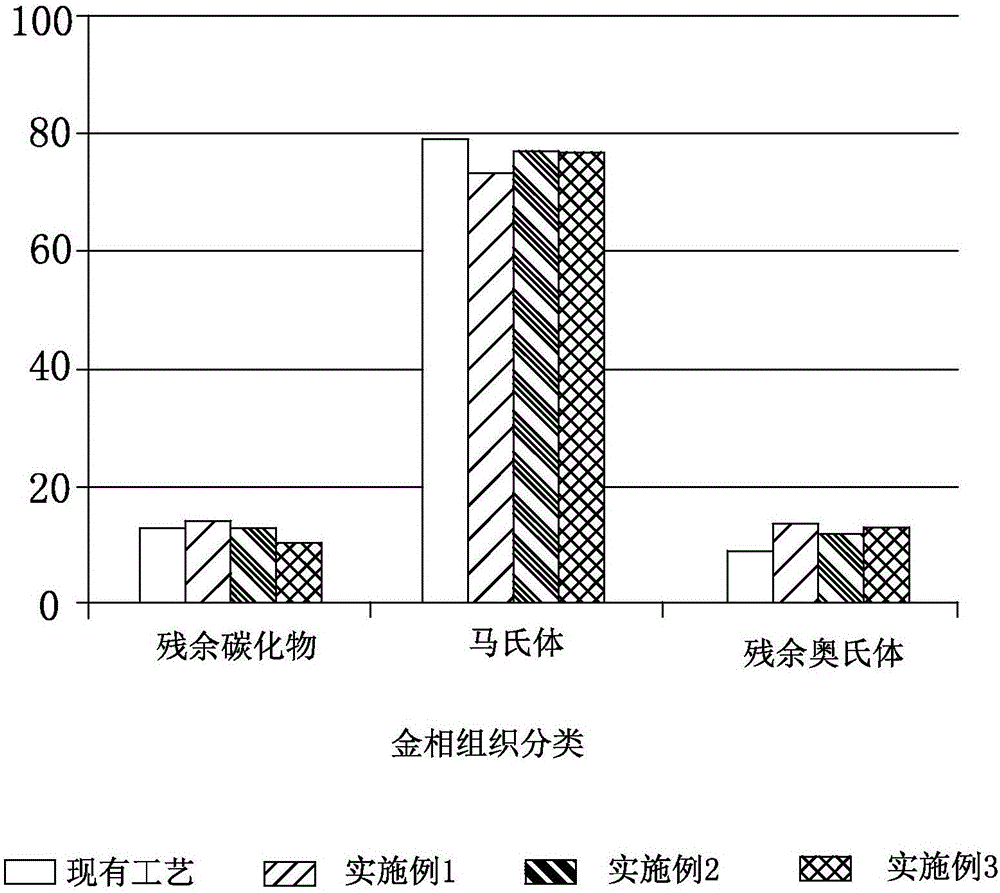

[0026] The material content of the bearing ring under the existing technology and the above-mentioned embodiment is detected: the content of retained austenite is detected by X-ray method; the content of residual carbide is counted by image binary method; the remaining content is the martensite content. get as figure 2 The chart shown.

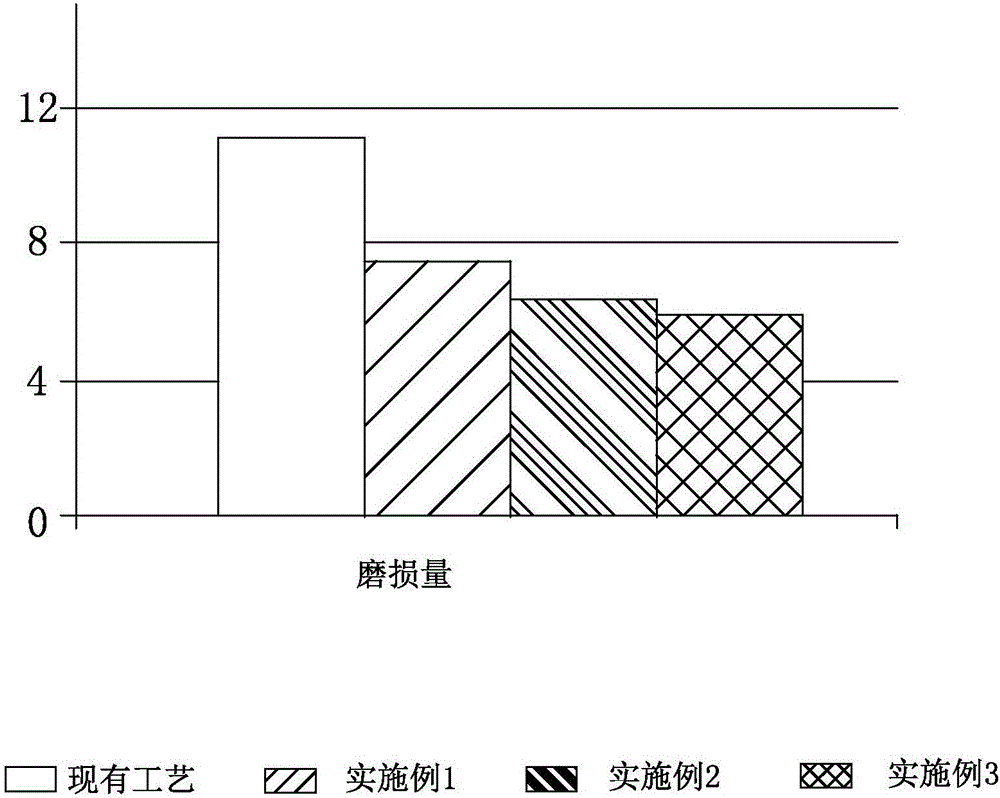

[0027] The wear test of the existing technology and the bearing rings of the above-mentioned exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com