Systems and Methods for Modeling Surface Properties of a Mechanical Component

a technology of mechanical components and systems, applied in the field of systems and methods for modeling can solve the problems of unpredictable measurement of the surface fatigue life and surface degradation rate of mechanical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

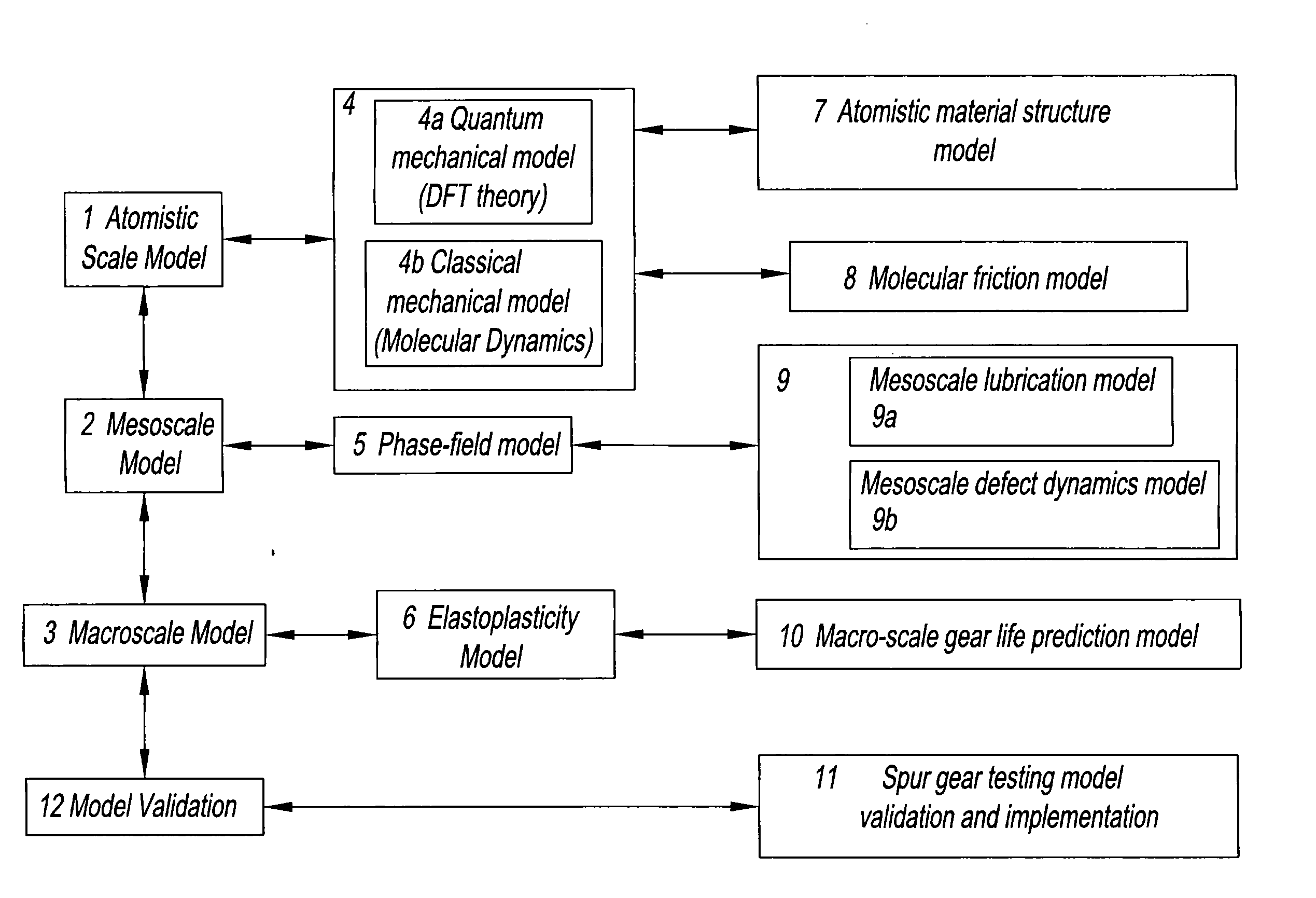

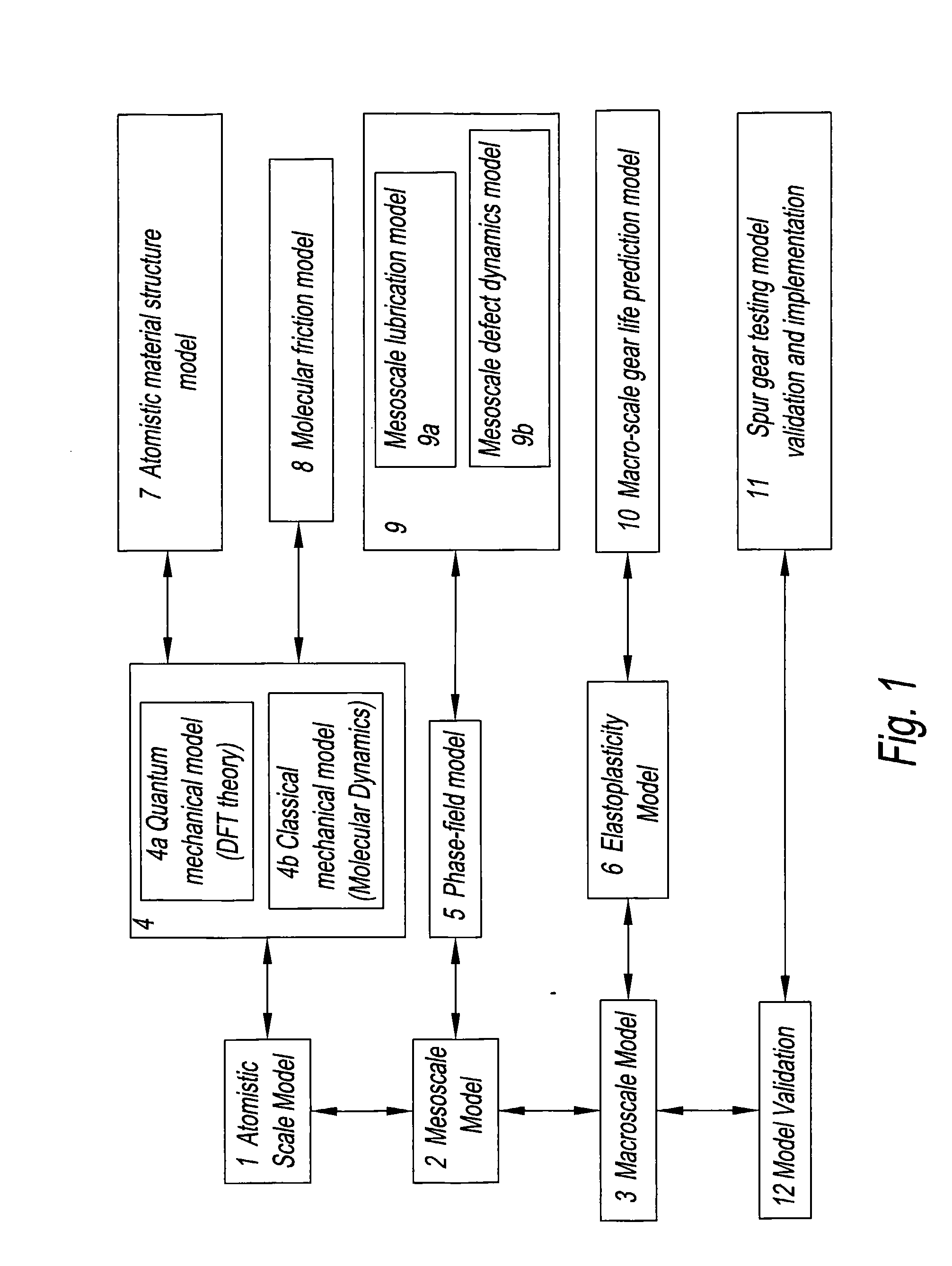

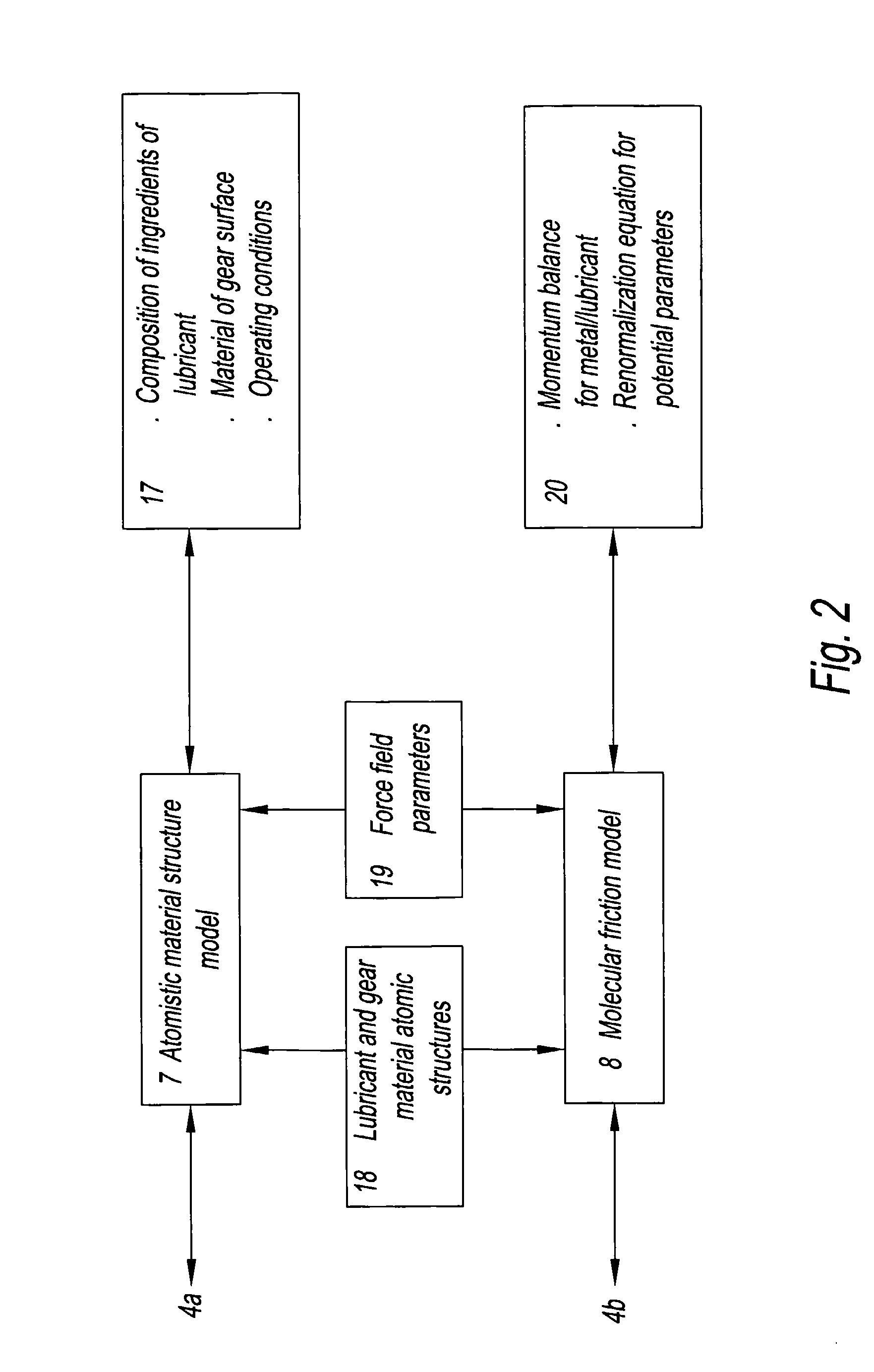

[0016]It was surprisingly found that the surface life fatigue and surface degradation rate of a mechanical component could be modeled. It was also surprisingly found that surface life fatigue and surface degradation rate could be predicted and characterized.

[0017]The system and method of the present invention are useful in predicting the surface life fatigue or surface degradation rate of mechanical components that are subject to repeated, cyclical mechanical and / or thermal stress. The system and method are useful, for example, with gears, bearings, splines, and springs. The system and method are particularly useful with interlocking / intermeshing gears, which are subject to repeated, cyclical mechanical stress. The system and method can be used with any type of gear, such as but not limited to a spur gear, worm gear, straight bevel gear, Zerol bevel gear, spiral bevel gear, helical gear, herringbone gear, double helical gear, hypoid gear, crossed helical gear, and the like.

[0018]The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com