Machine tool comprising a device for collision monitoring

A technology of collision detection and machine tools, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Preferred embodiments of the present invention are described in detail below with reference to the accompanying drawings. However, the invention is not limited to the described embodiments. The present invention is defined by the scope of the claims. Identical and / or similar features of the embodiments are denoted by the same numerical references.

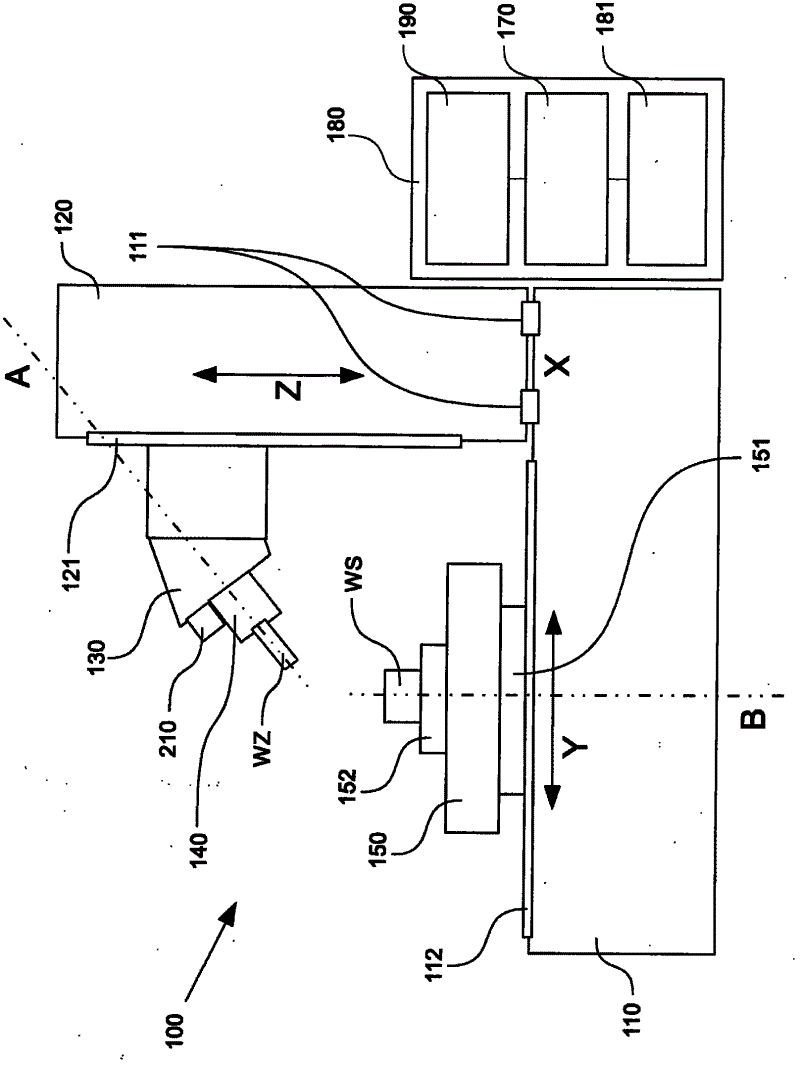

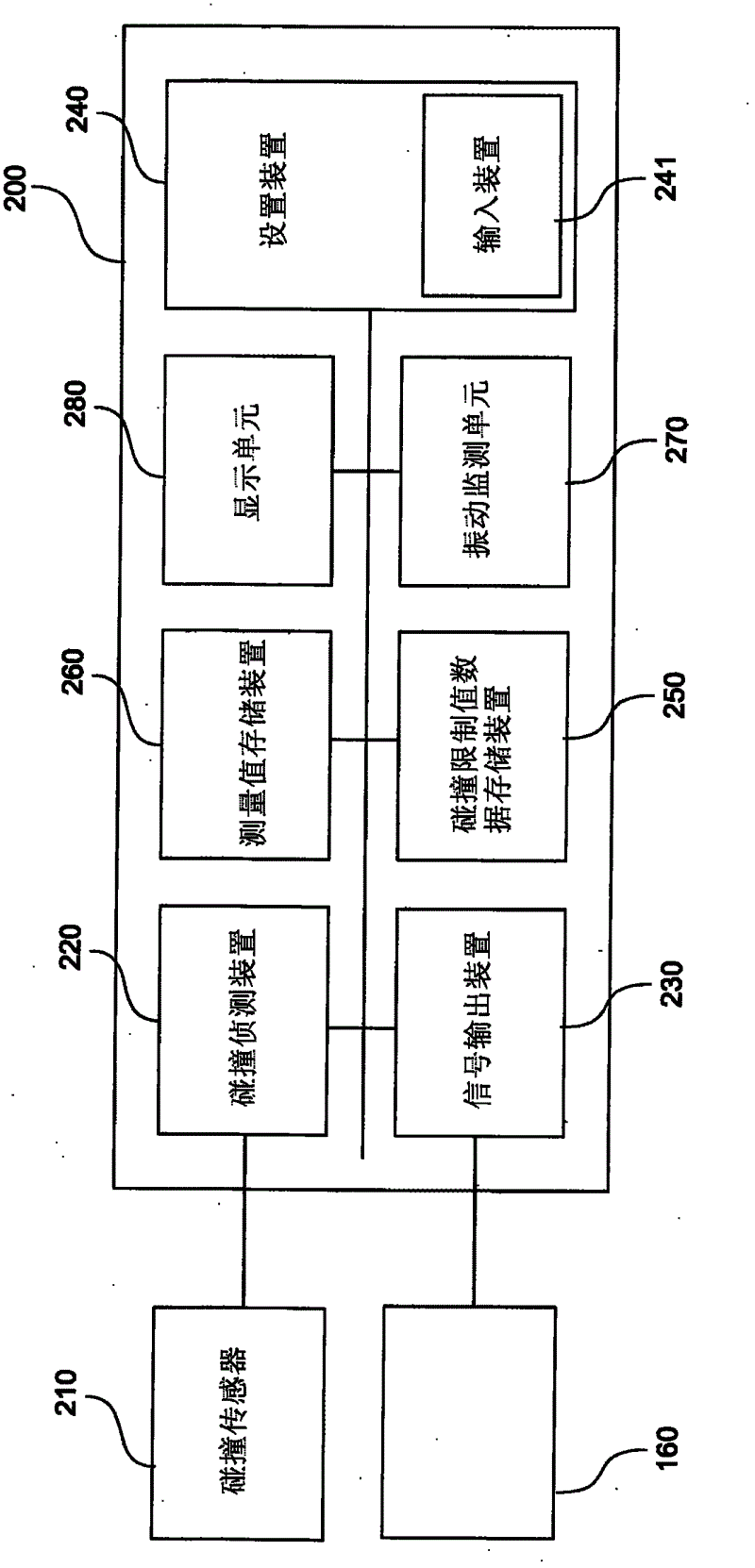

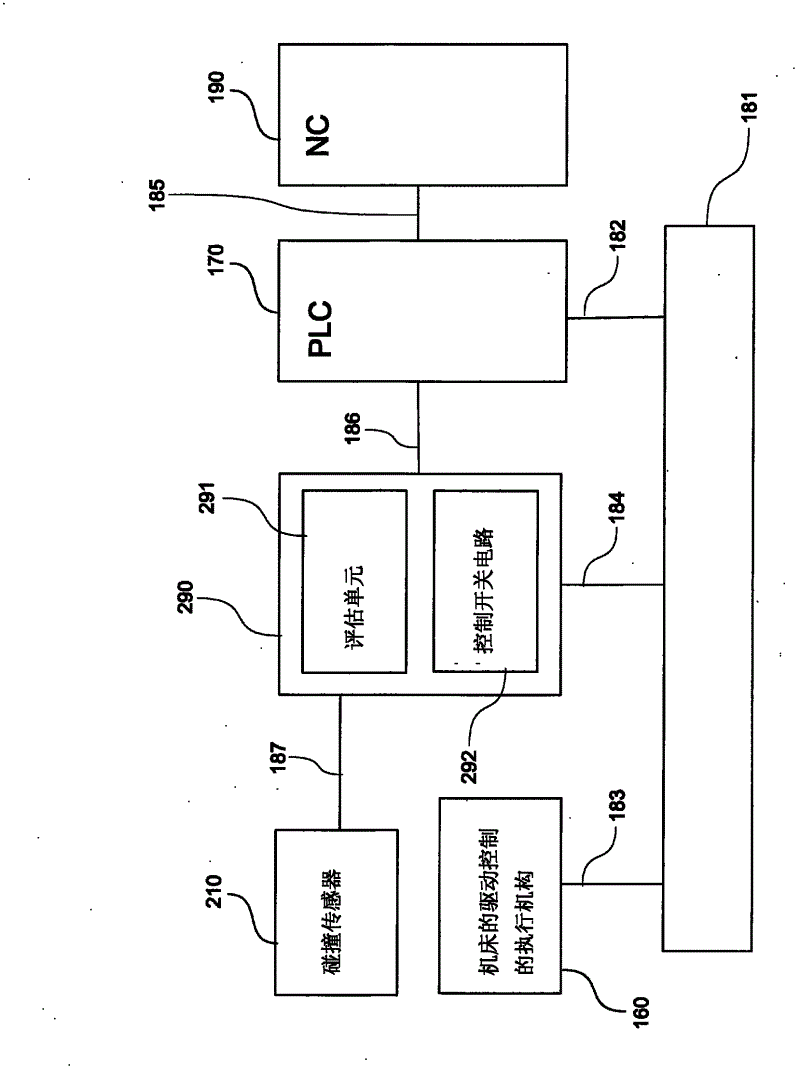

[0075] figure 1 A schematic diagram of an embodiment of a numerically controlled machine tool 100 for machining a workpiece WS is shown. The workpiece WS is clamped on a clamping device 152 provided on the turntable 150 of the machine tool 100, so that the workpiece is fixed in rotation and can be rotated by a rotating shaft B (see figure 1 The vertical rotation axis in the) rotation drive. As an embodiment, the turntable 150 can be moved by a support frame 151 installed on the Y-direction guide rail 112 on the bed 110 of the machine tool, and the support frame 151 moves along the Y guide rail 112 in the Y direction thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com