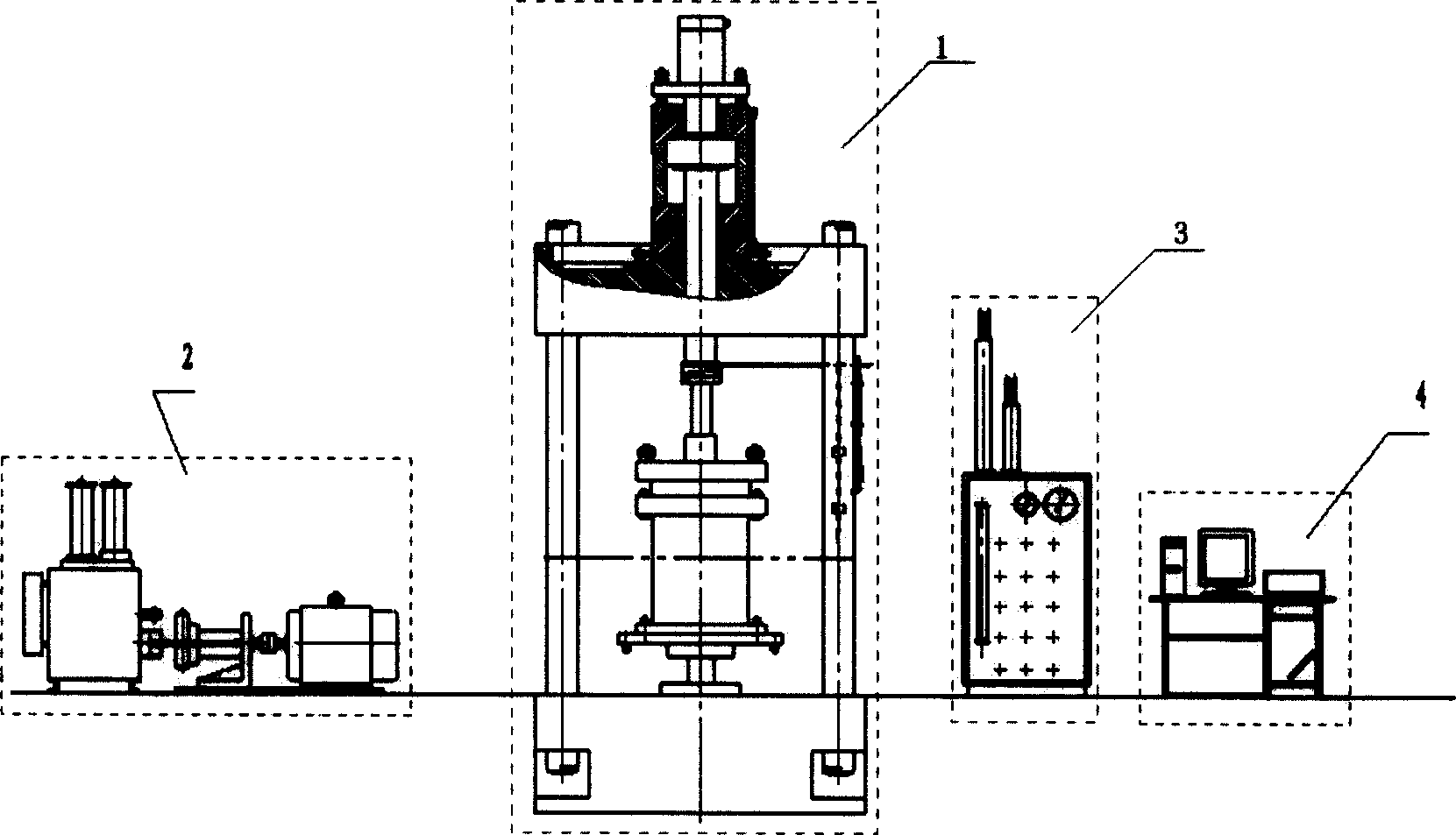

Large-sized multifunction material three-shaft static-dynamic test machine

A multi-functional, testing machine technology, used in material inspection products, analytical materials, soil material testing, etc., can solve problems such as insufficient stiffness, testing, and testing machines without soil, rock and concrete materials, and achieve high component utilization and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

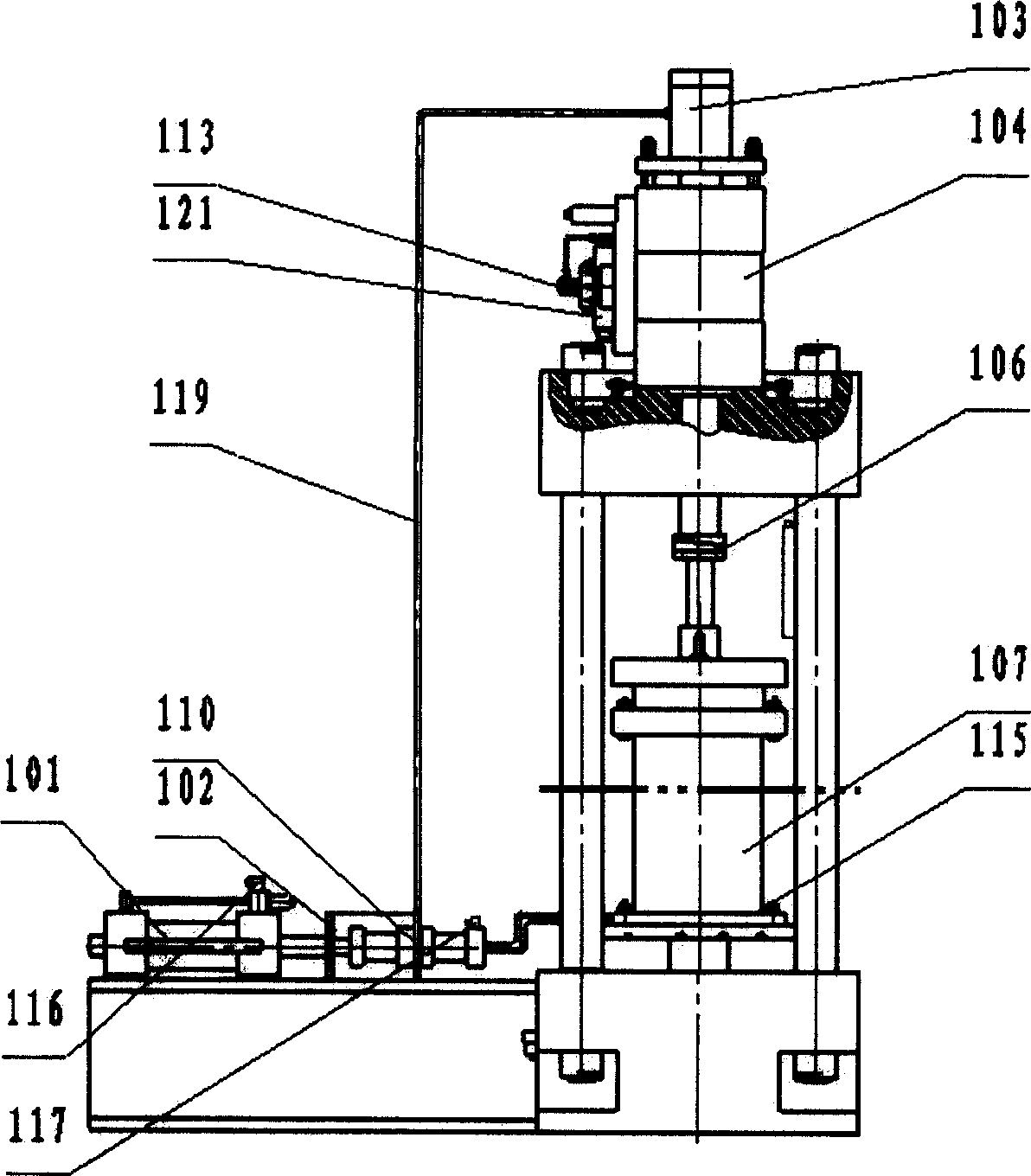

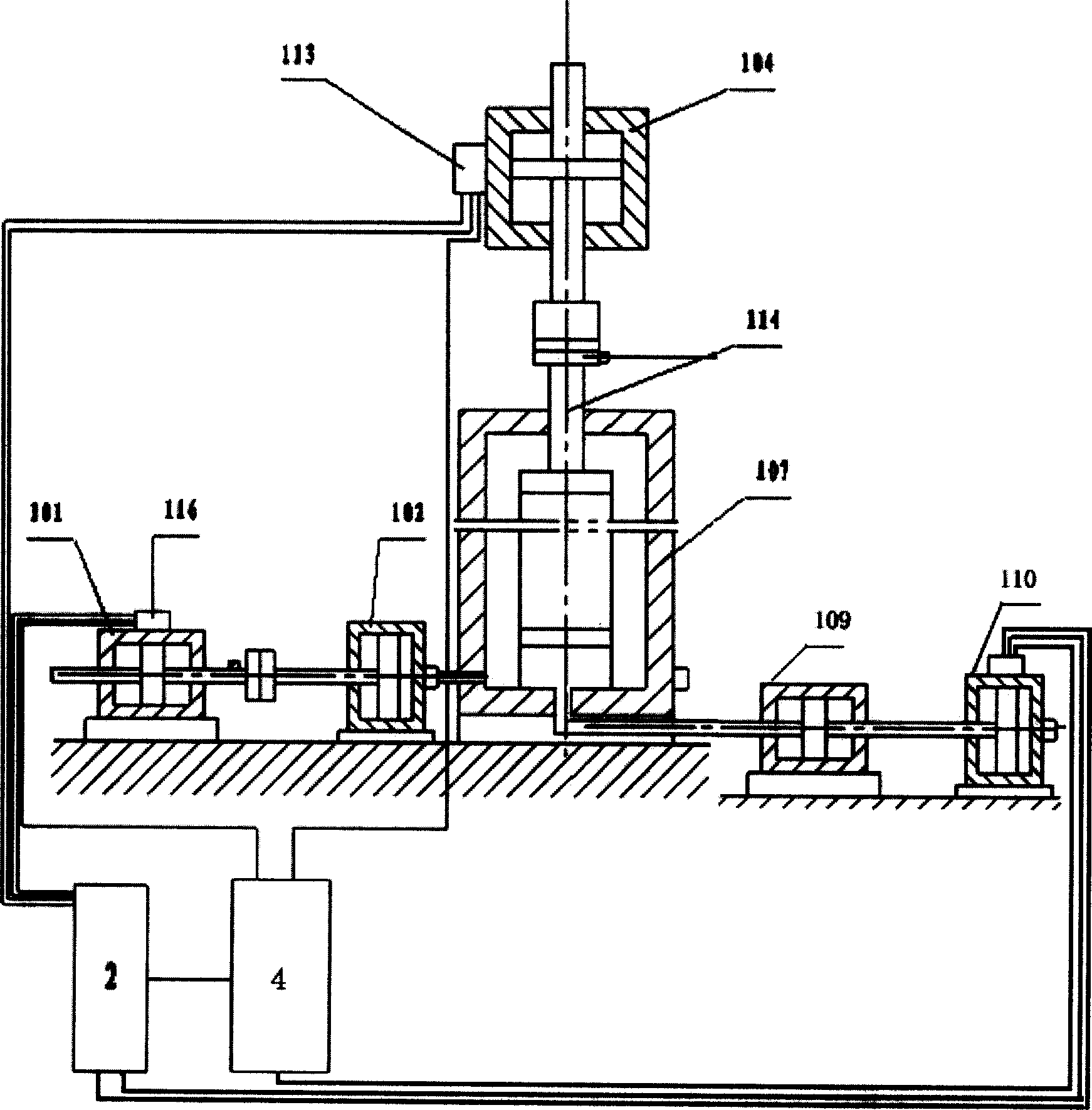

[0014] The multifunctional material three-axis static and dynamic testing machine provided by the present invention is realized by the following key technologies:

[0015] 1) In order to meet the needs of different material tests, a hydraulic system with parallel oil sources is adopted, which can be flexibly added at any time according to the amount of oil required for the test;

[0016] 2) In order to overcome the pressure instability of the triaxial pressure chamber caused by the axial load or the instability of the axial load caused by the confining pressure load, the pressure stabilizing equipment connected with the triaxial pressure chamber is adopted to achieve the internal pressure of the system. The water quality is constant to ensure the pressure stability of the pressure chamber;

[0017] 3) In order to realize the active control of the pore pressure of the sample, an independent electro-hydraulic servo control system is used to participate in the measurement and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com