Method and device for detecting sample axle through ultrasonic

An ultrasonic and shaft device technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of only downgraded use, waste of cost, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

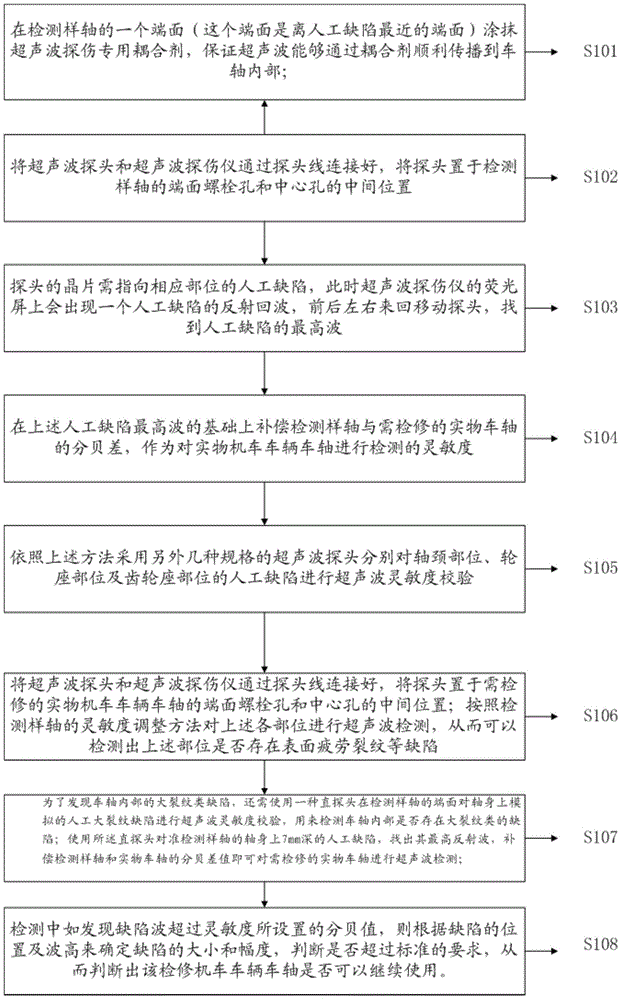

[0025] In order to have a clearer and more comprehensive understanding of this patent, its specific implementation methods are now described as follows:

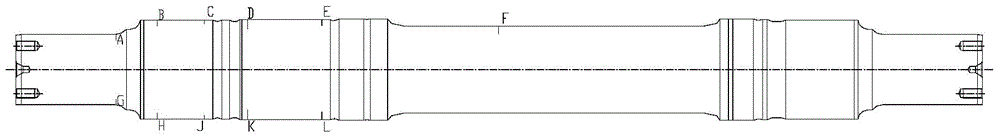

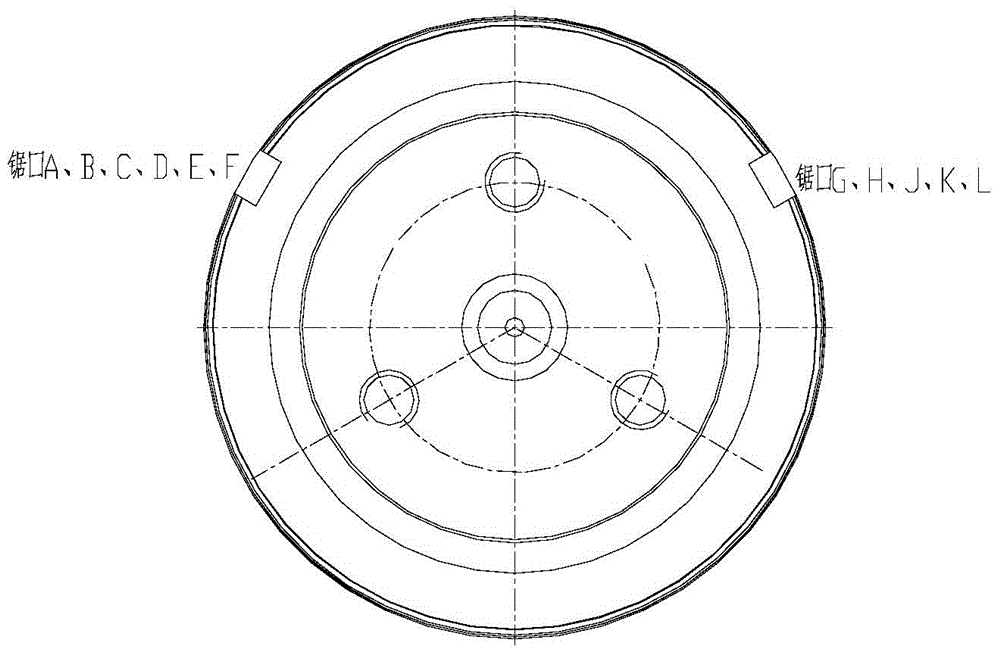

[0026] The detection sample shaft of this patent is manufactured by the following method:

[0027] First, use the same material as the overhauled locomotive and vehicle axle (such as: A1N, 35CrMoA, EA4T, JZ35, etc.) to make a finished axle; this axle needs to be refined through forging, heat treatment, rough turning and fine turning. , the grain size of the testing shaft is ≥ 8 grades; the roughness of the end surface and the outer surface of the shaft reaches the Ra ≤ 6.3 μm required by the testing standard, and then the testing shaft is subjected to an ultrasonic sound permeability test (defects are not allowed inside the shaft) ), after passing the inspection, just obtained the finished rolling stock axle shaft of prior art.

[0028] The rolling stock inspection sample shaft needs to process three kinds of artificial def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com