Chain processing technology

A processing technology and chain technology, applied in the direction of metal material coating technology, manufacturing tools, coatings, etc., can solve the problems of paint waste, carrying a large amount of paint, etc., to improve the uniformity, improve the painting effect, and improve the organizational structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

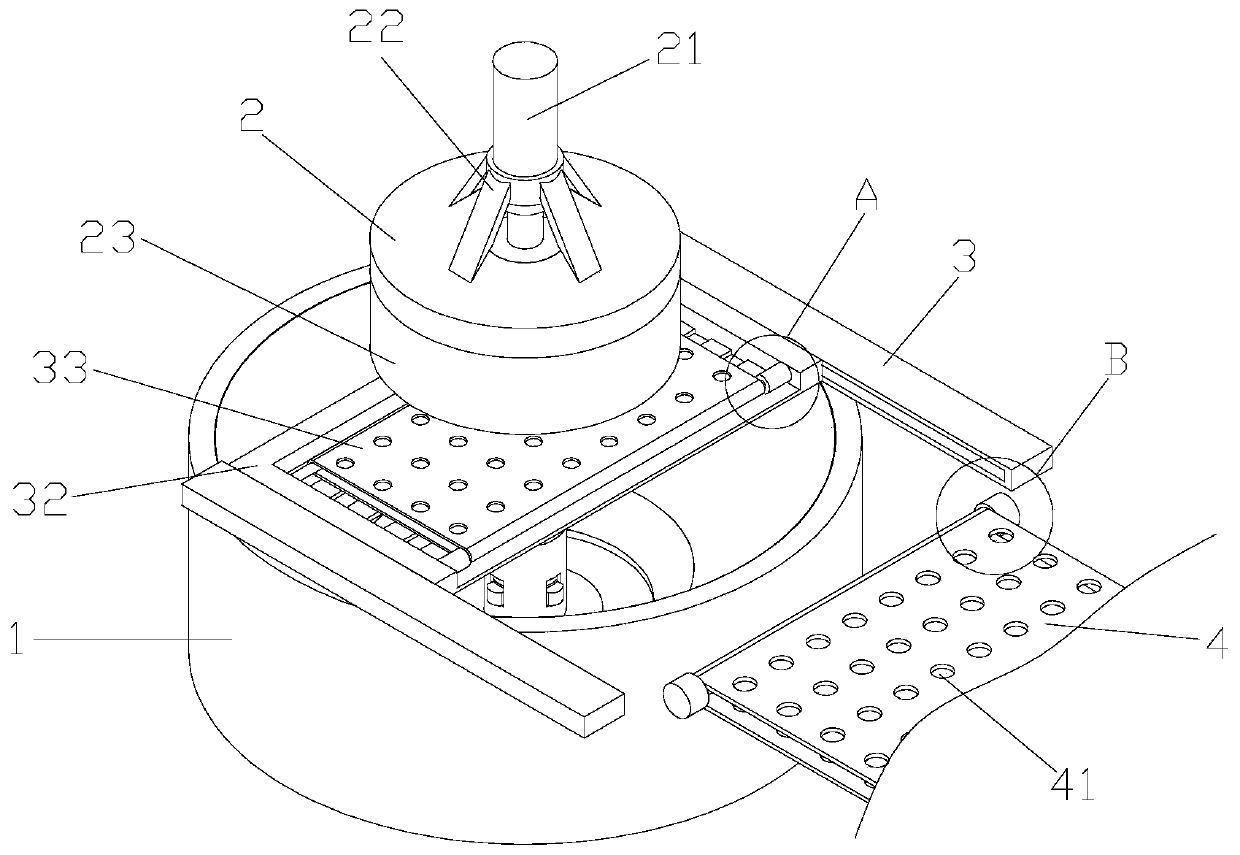

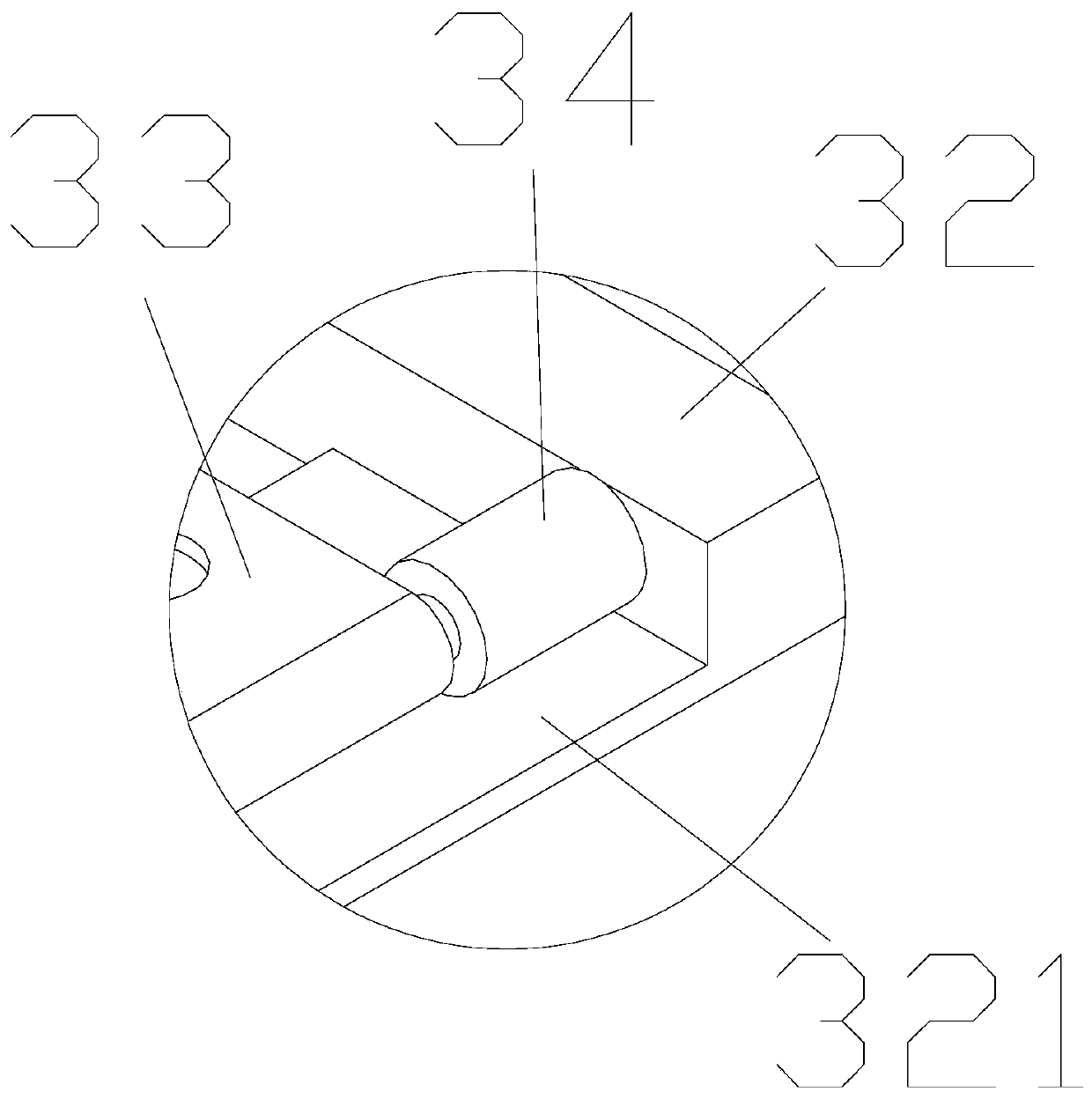

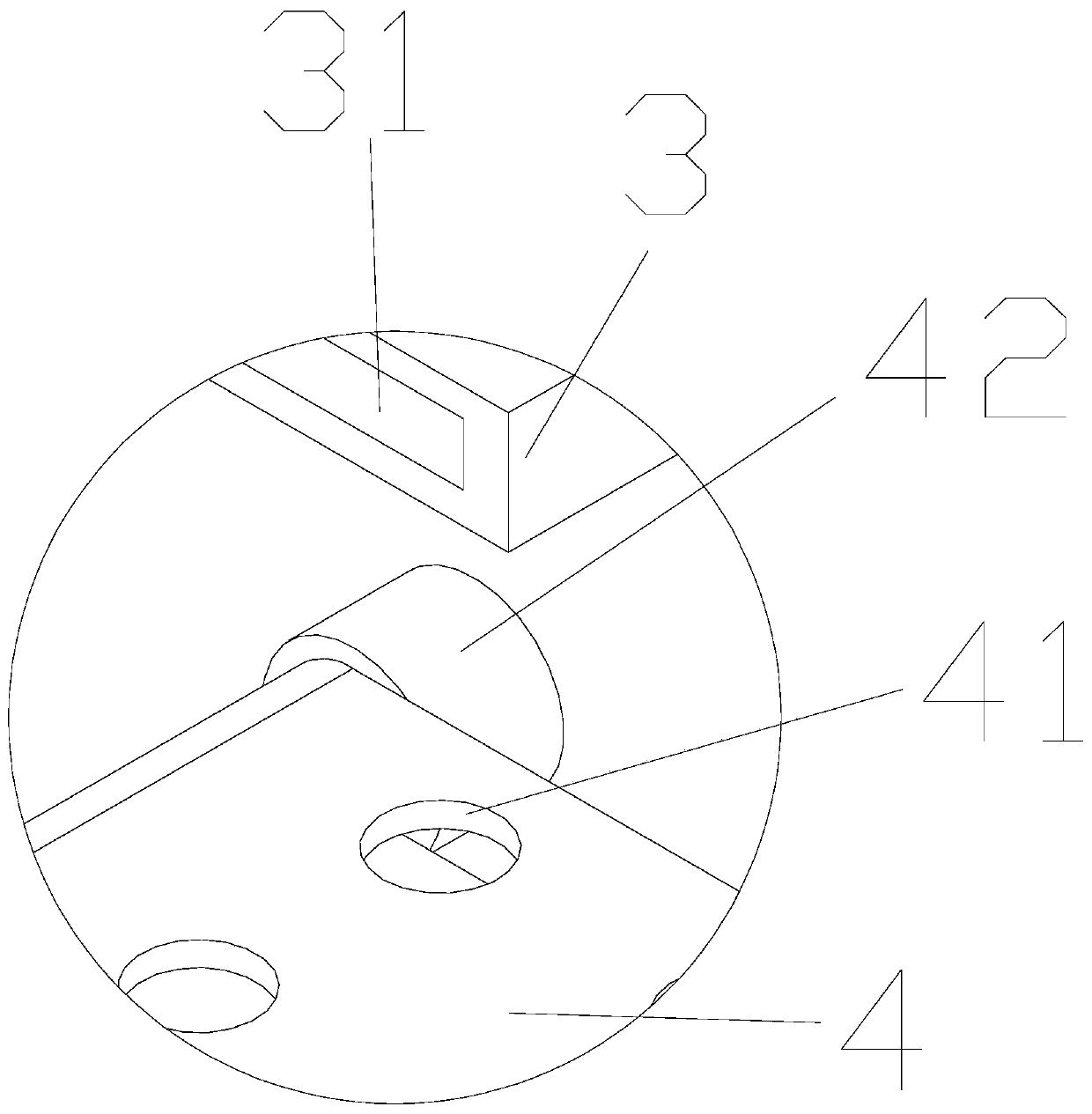

Image

Examples

Embodiment 1

[0036] A chain processing technology, including: a. heat treatment: in heat treatment equipment, various auxiliary media are used at high temperature to improve the structure of parts and improve the performance of various items; b. carburizing: place parts in heat treatment equipment Heating and keeping warm, and then passing through carbon-containing medium to infiltrate carbon into the surface of the parts to improve the hardness and wear resistance of the chain; c. Quenching: the parts are heated in the heat treatment equipment and kept warm, and then cooled in different media according to requirements, so that Improve the hardness of the parts; d. Tempering: the quenched parts are heated at a specific temperature in the heat treatment equipment, and then cooled after being kept warm; e. Blackening: the principle of polymer organic polymerization is adopted, and the residual heat of tempering during the heat treatment process is used Blackening of the film; f, blue: after h...

Embodiment 2

[0052] A chain processing technology, including: a. heat treatment: in heat treatment equipment, various auxiliary media are used at high temperature to improve the structure of parts and improve the performance of various items; b. carburizing: place parts in heat treatment equipment Heating and keeping warm, and then passing through carbon-containing medium to infiltrate carbon into the surface of the parts to improve the hardness and wear resistance of the chain; c. Quenching: the parts are heated in the heat treatment equipment and kept warm, and then cooled in different media according to requirements, so that Improve the hardness of the parts; d. Tempering: the quenched parts are heated at a specific temperature in the heat treatment equipment, and then cooled after being kept warm; e. Blackening: the principle of polymer organic polymerization is adopted, and the residual heat of tempering during the heat treatment process is used Blackening of the film; f, blue: after h...

Embodiment 3

[0054] A chain processing technology, including: a. heat treatment: in heat treatment equipment, various auxiliary media are used at high temperature to improve the structure of parts and improve the performance of various items; b. carburizing: place parts in heat treatment equipment Heating and keeping warm, and then passing through carbon-containing medium to infiltrate carbon into the surface of the parts to improve the hardness and wear resistance of the chain; c. Quenching: the parts are heated in the heat treatment equipment and kept warm, and then cooled in different media according to requirements, so that Improve the hardness of the parts; d. Tempering: the quenched parts are heated at a specific temperature in the heat treatment equipment, and then cooled after being kept warm; e. Blackening: the principle of polymer organic polymerization is adopted, and the residual heat of tempering during the heat treatment process is used Blackening of the film; f, blue: after h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com