Automatic oiling device for automobile brake component assembling

A technology for component assembly and automobile braking, applied in the direction of injection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

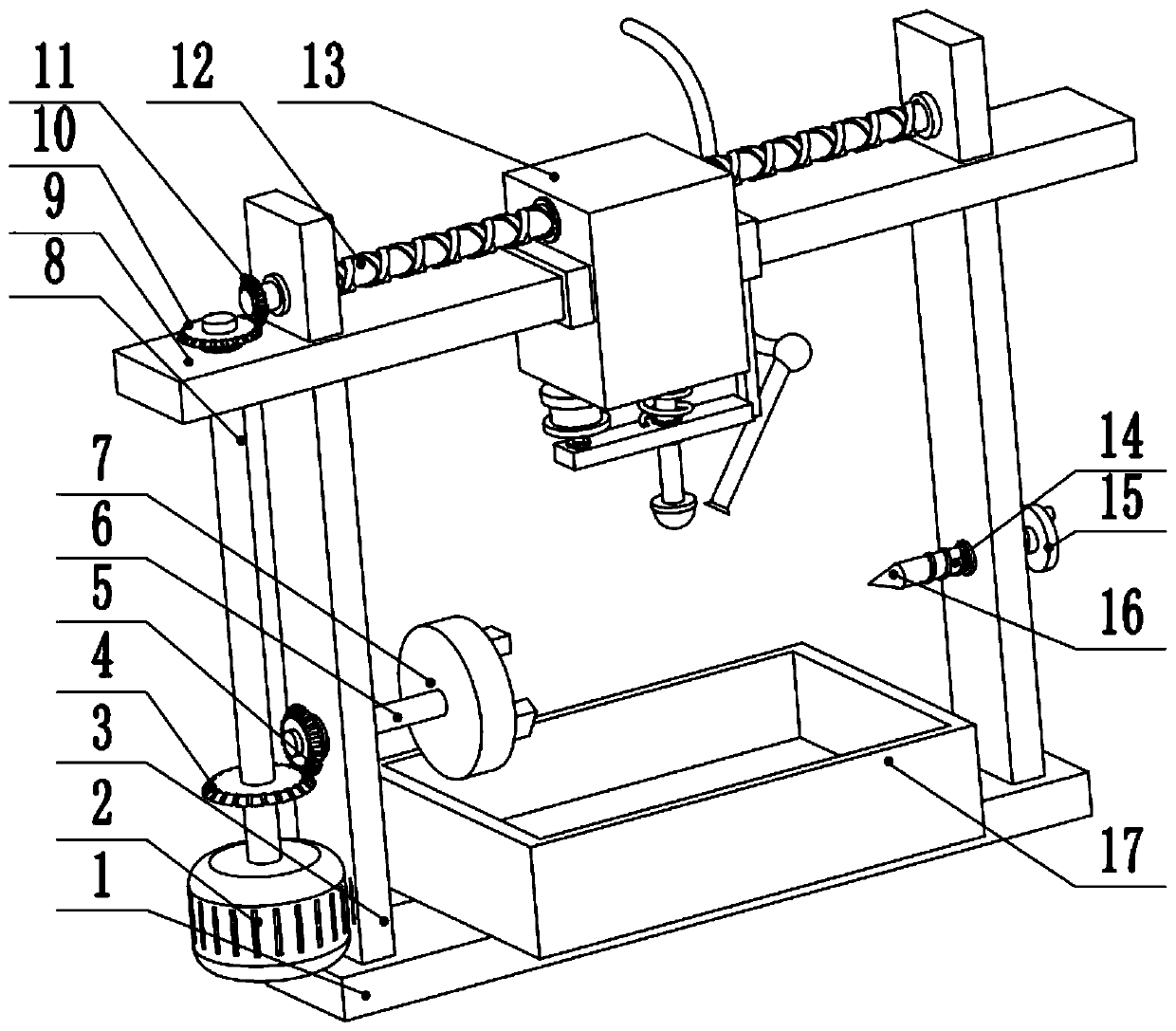

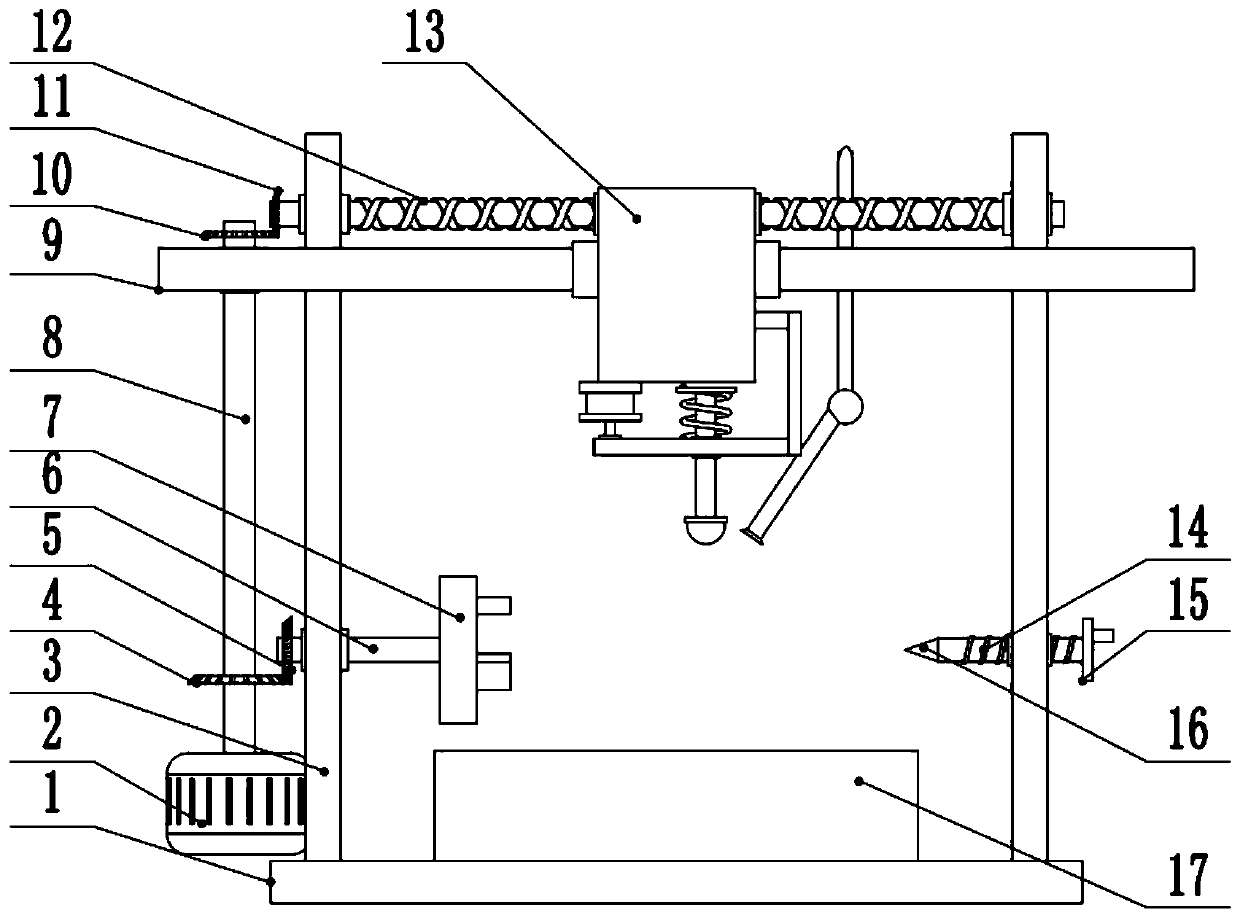

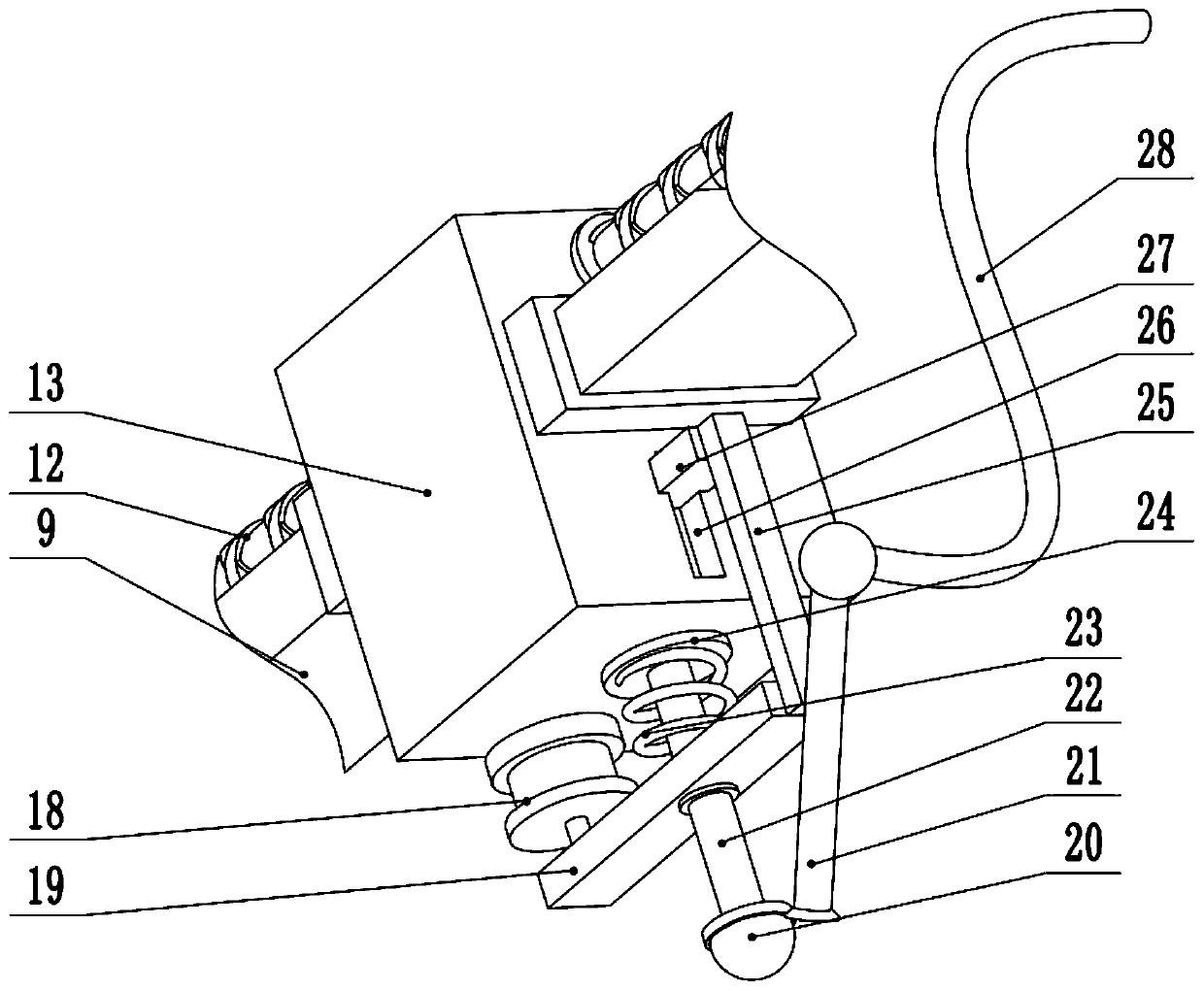

[0025] see Figure 1-3 , an automatic oiling device for assembly of automobile brake parts, comprising a base plate 1, an oil storage tank 17 is provided in the middle of the base plate 1, side plates 3 are provided on the left and right sides of the base plate 1, and the upper part of the side plate 3 is fixedly connected to the top plate 9, left The bottom of the side plate 3 is provided with a driving motor 2, the output shaft of the driving motor 2 is fixedly connected to the rotating shaft 8, the bottom of the rotating shaft 8 is provided with a first bevel gear 4, and the first bevel gear 4 is meshed with the second bevel gear 5, The second bevel gear 5 is fixedly connected to the left end of the rotating rod 6, the middle part of the rotating rod 6 is connected to the side plate 3 on the left side in rotation, and the right end of the rotating rod 6 is provided with a fixed seat 7, and the fixed seat 7 can adopt a three-catch chuck to ensure that the workpiece can be sta...

Embodiment 2

[0028] The other content of this embodiment is the same as that of Embodiment 1, the difference is that: the bottom of the side plate 3 on the right is connected to the threaded rod 14 by rotation, the left side of the threaded rod 14 is provided with a plug 16, and the right side of the threaded rod 14 is provided with a Hand wheel 15, the center of rotation of threaded rod 14 is concentric with the center of rotation of turning rod 6. Because the fixed seat 7 can only fix one end of the workpiece, and when the fixed seat 7 drives the workpiece to rotate, the right end of the workpiece may shake. 16. Press the plug 16 tightly on the right end of the workpiece through the threaded rod 14, so as to play a certain supporting role for the workpiece. Prevent the workpiece from shaking during rotation.

[0029] In the implementation process of the present invention, at first the left end of the workpiece is fixed in the fixed seat 7, and the oil pipe 28 is connected with the oil s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com