Multi-level flywheel body oiling machine

An oil injection machine and flywheel technology, which is applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve the problems of low work efficiency, uneven oil injection, high labor intensity, etc., and achieve the effect of high speed and good oil injection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

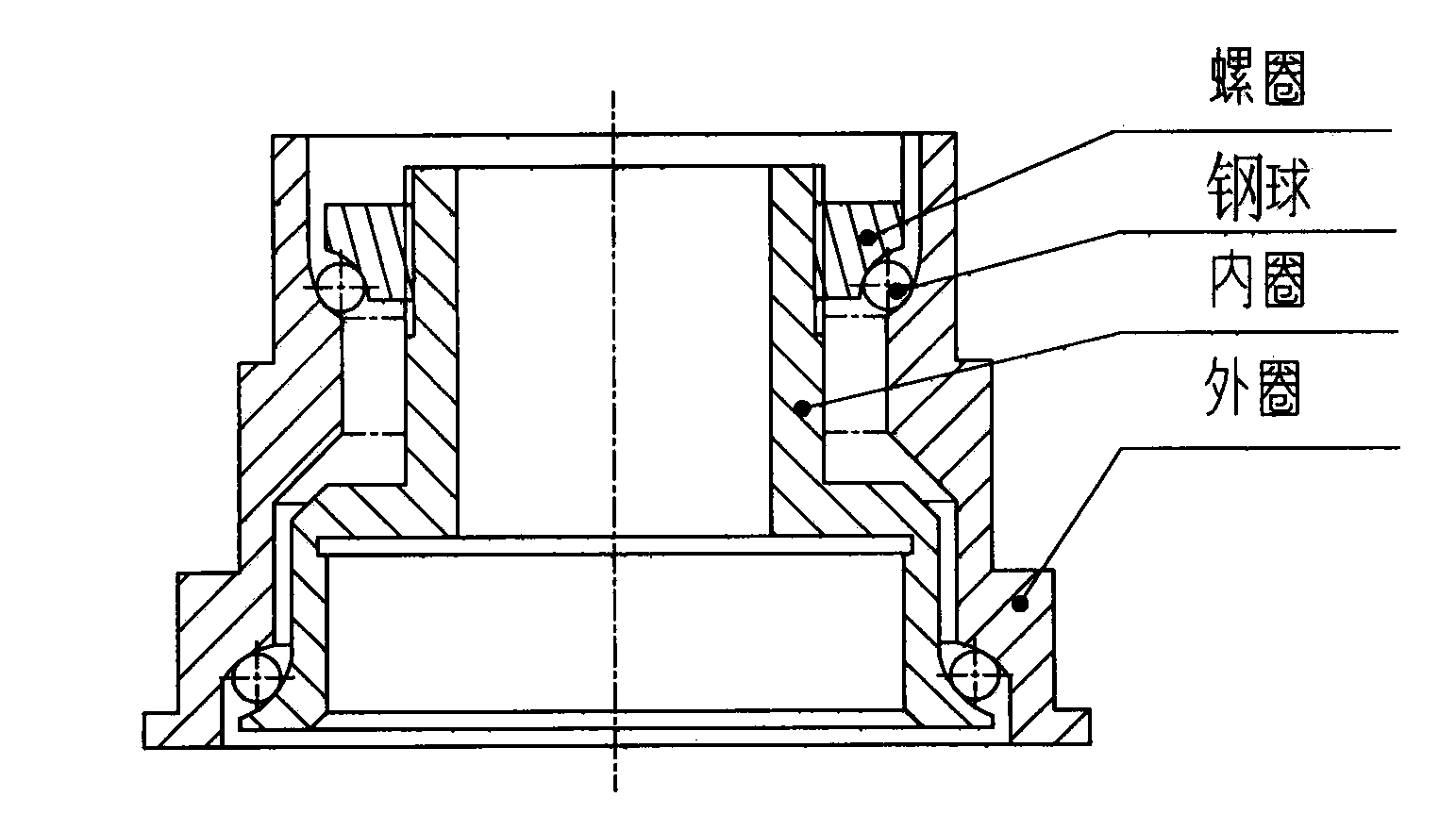

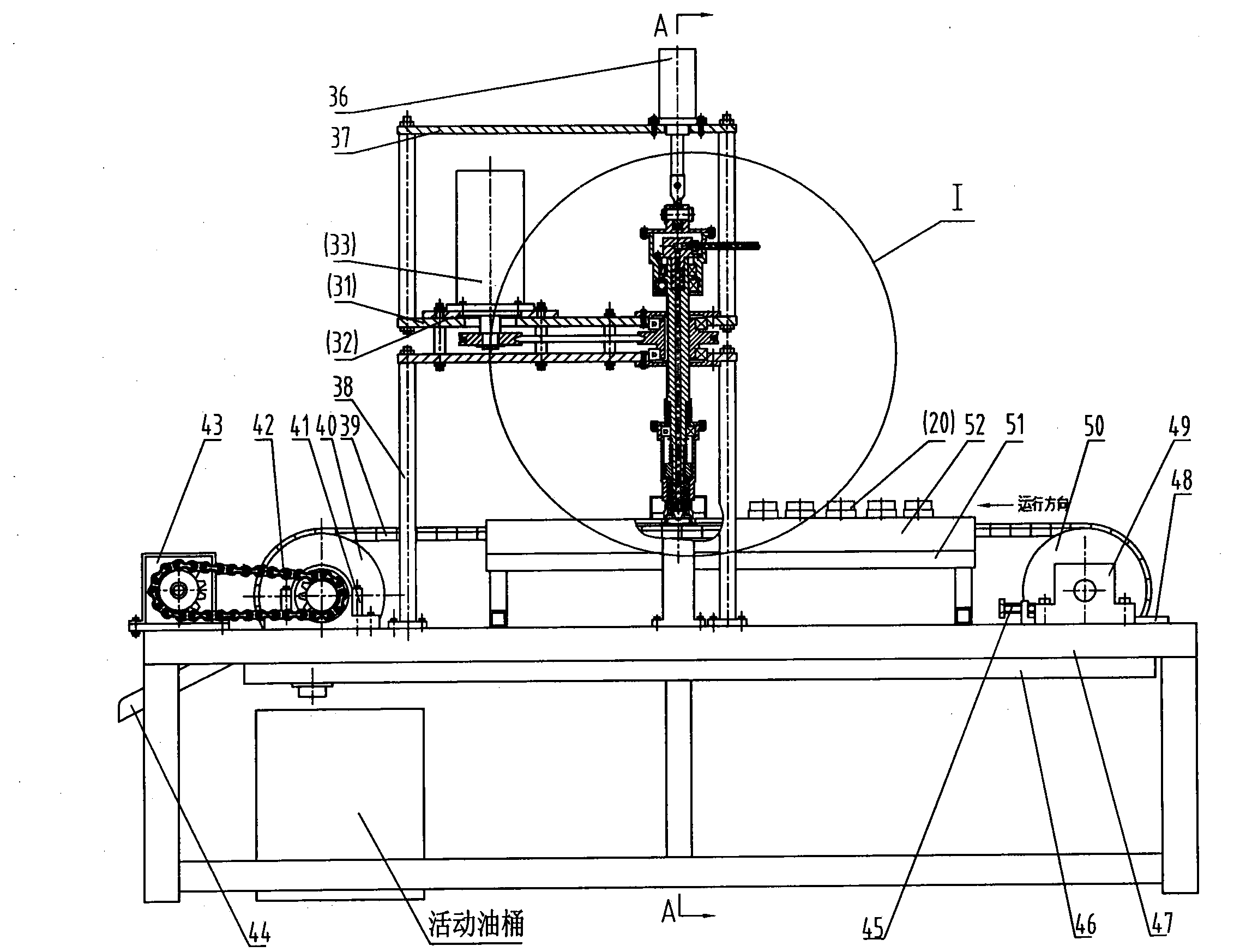

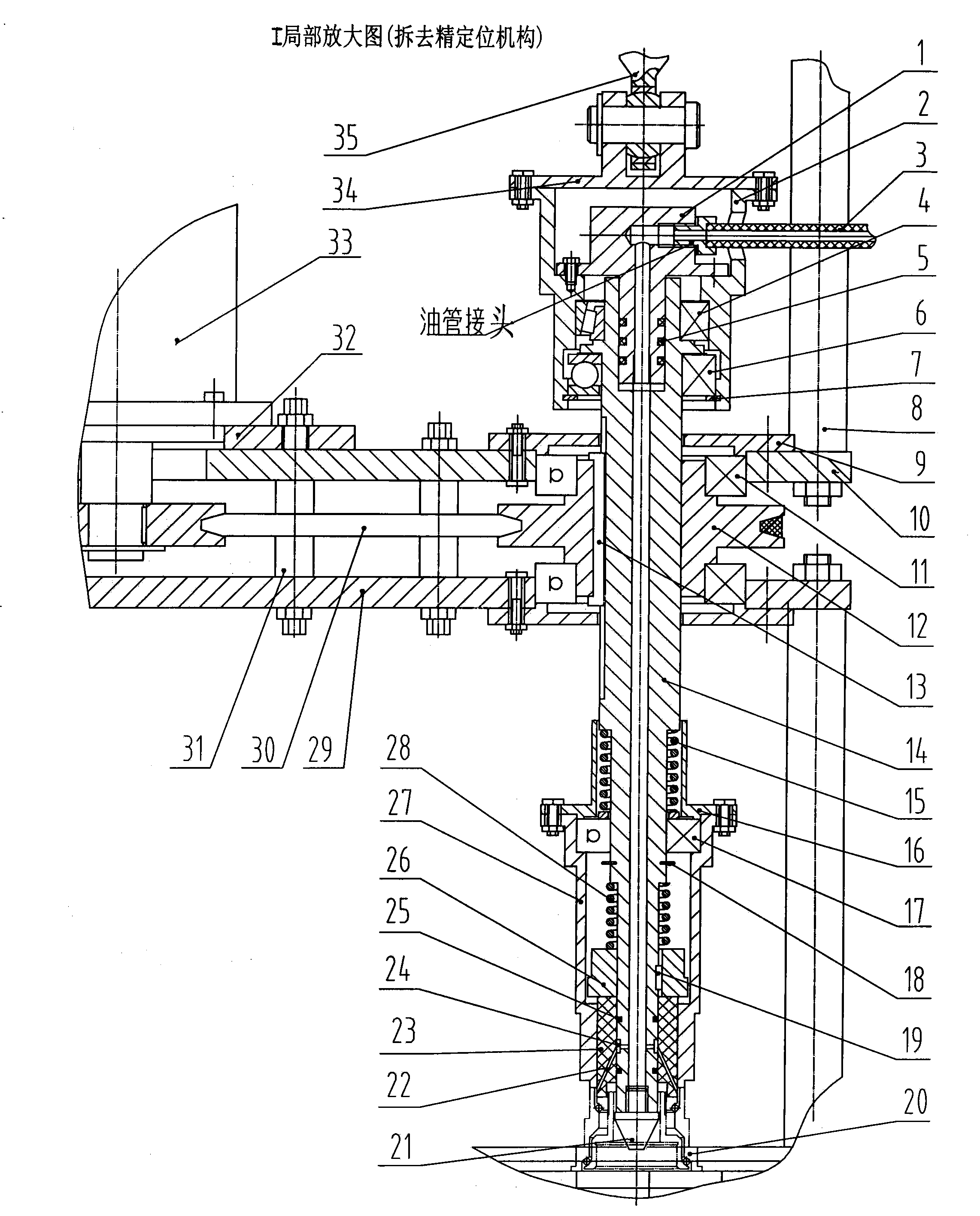

[0015] Below in conjunction with accompanying drawing, the present invention will be described in further detail, as figure 2 Shown, the present invention mainly is made up of frame 47, conveyor belt mechanism, positioning mechanism and oiling rod parts. like figure 2 , Figure 4 Shown, conveyor belt mechanism comprises speed-regulating motor 43, conveyor belt 39, driving wheel 40, tail wheel 50, limit plate 52, supporting bar 57 and oil pan 46 etc., and its driving wheel 40 uses speed-regulating motor 43 to pass chain 42 Drive, the driving wheel 40 drives the conveyor belt 39 to run; the tail wheel bearing seat 49 is connected with the fixed slideway 48 on the frame, and the tension can be adjusted by the screw rod 45; To ensure that the conveyor belt 39 is always kept level during operation; fixedly install limit plates 52 on both sides of the working surface of the conveyor belt 39, so that the flywheel body runs along the fixed track; a fixed oil pan 46 is provided bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com