Oil coating structure of calendaring machine

A technology of calendering and oiling, which is applied in the direction of coating and liquid coating on the surface, etc. It can solve the problems of easy adsorption and adhesion of plastic films, difficulty in spraying silicone oil evenly, and weakened antistatic ability, so as to increase the antistatic capacity. Electrostatic capacity, uniform force, good oiling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

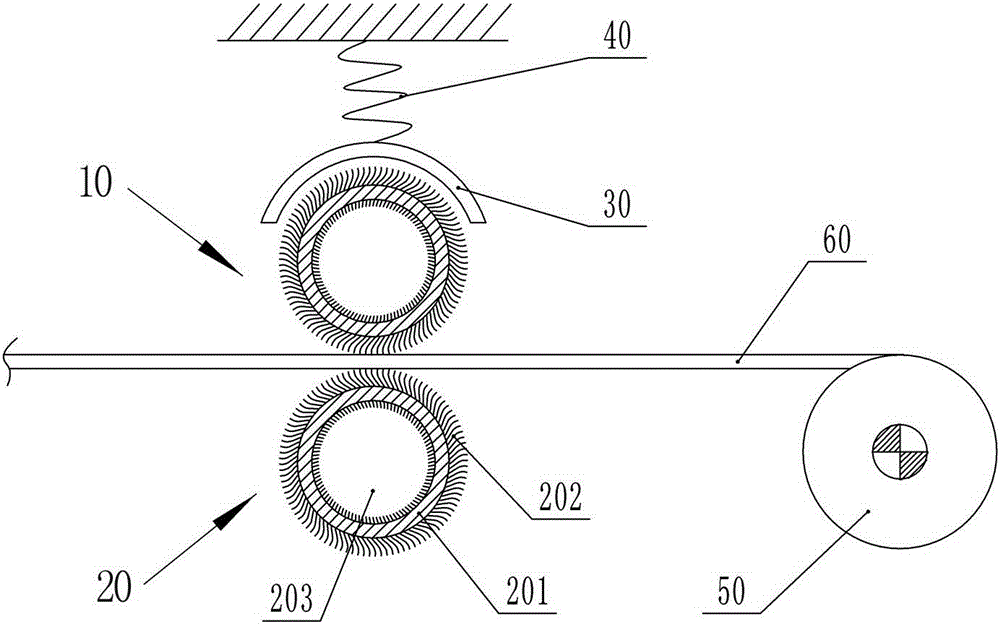

[0014] The reference signs in the drawings of the description include: the first brush roller 10, the second brush roller 20, the rotating roller 201, the bristles 202, the material storage chamber 203, the bearing bush 30, the elastic member 40, the winding roller 50, the plastic film 60.

[0015] Such as figure 1 As shown, the calender oiling structure includes an elastic member 40, a bearing bush 30, a first brush roller 10 and a second brush roller 20, and the first brush roller 10 and the second brush roller 20 are all rotatably arranged on the frame superior. The first fur brush roller 10 is located above the second fur brush roller 20 . Both the first brush roller 10 and the second brush roller 20 include a rotating roller 201 and bristles 202 . And all are provided with storage cavity 203 and feed door. The bristles 202 are inserted into the storage cavity 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com